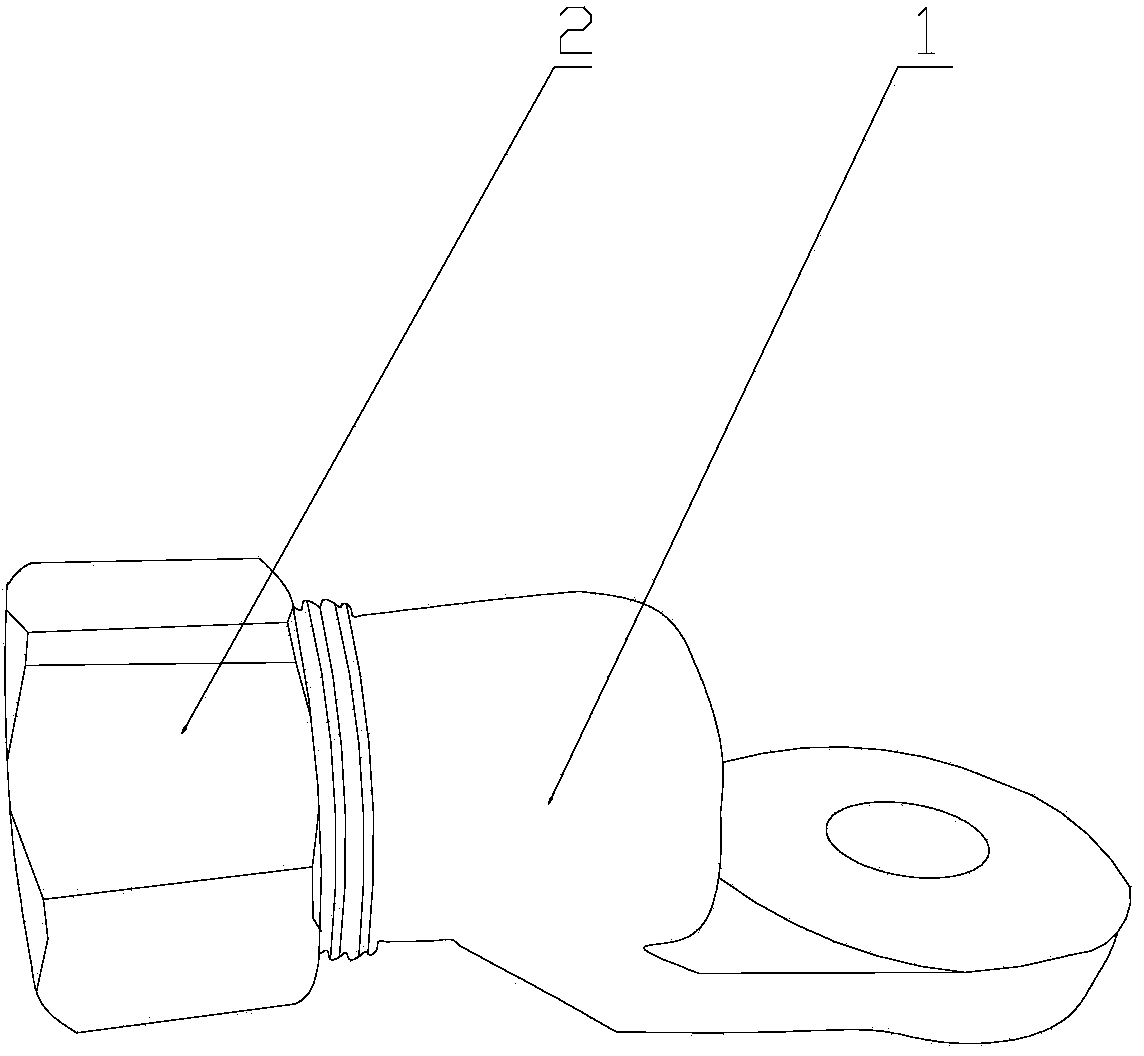

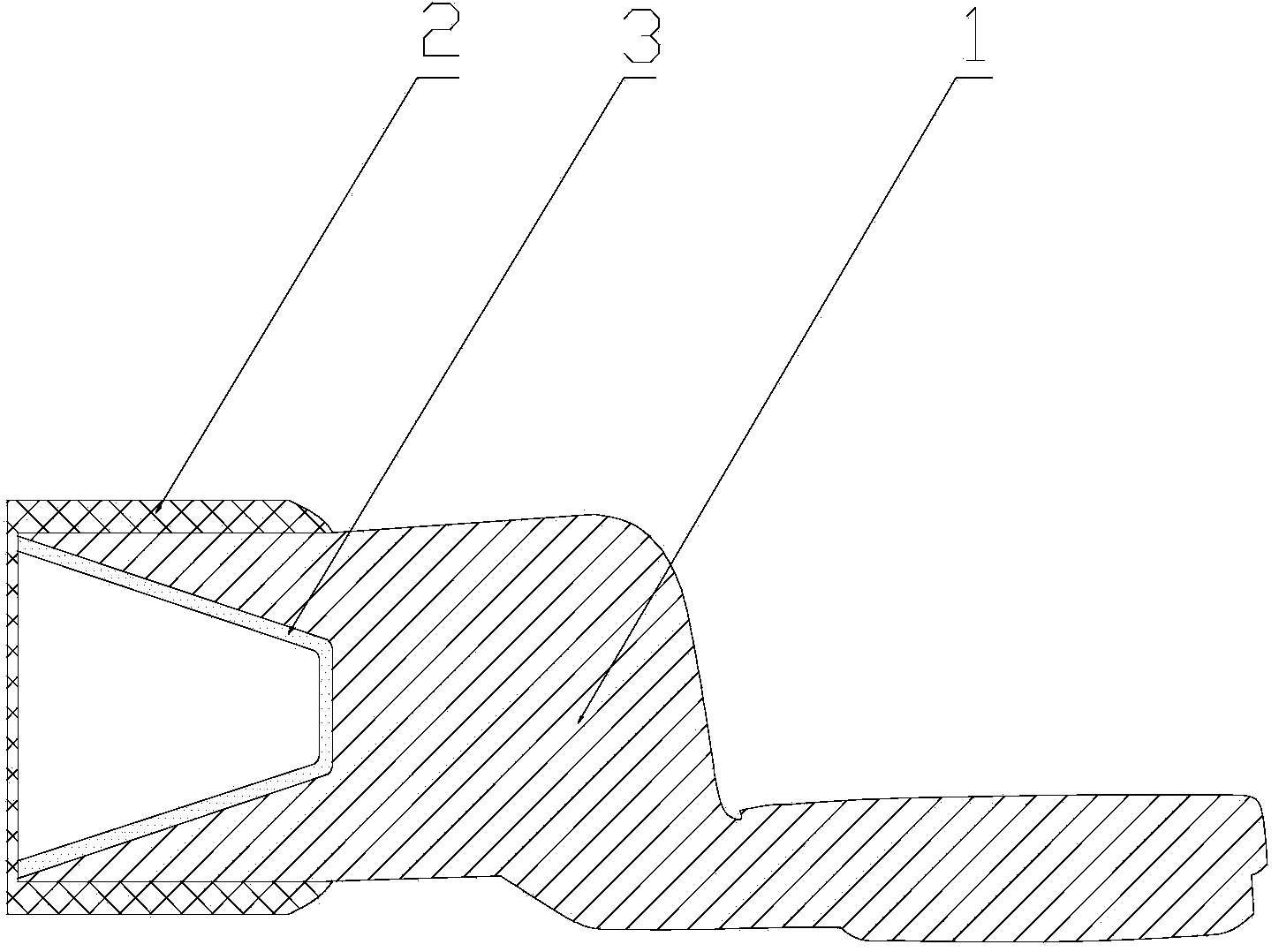

Taper press-fitting cable wiring terminal

A terminal and press-fit technology, applied in the field of tapered press-fit cable terminals, can solve the problems of unreasonable structural design, difficult processing operation, high processing cost, etc., and achieve ingenious structural design, strong practical value and low processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

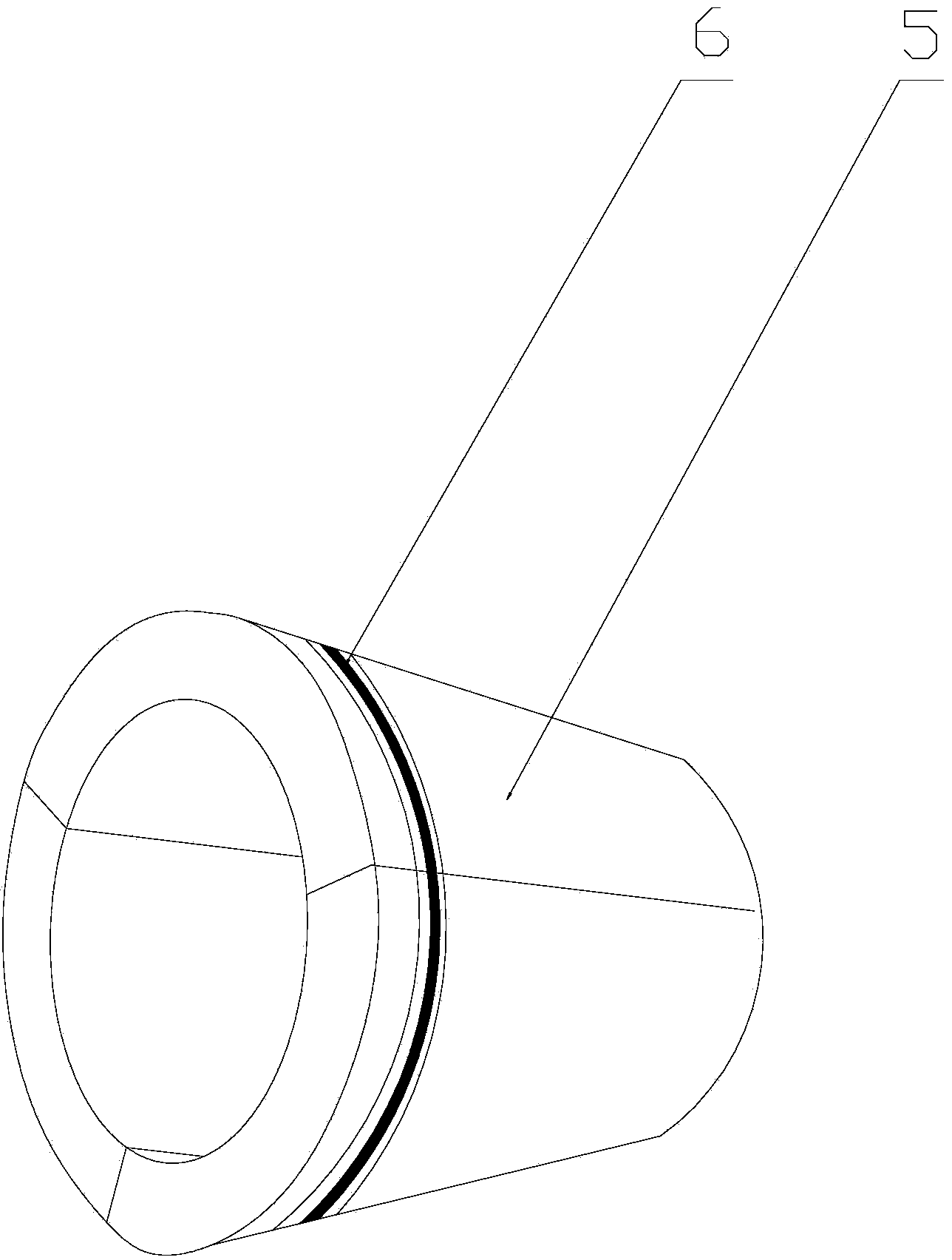

[0022] as attached image 3 As shown, three press-fitted inclined blocks 5 with grooves 4 cooperate with each other to form a whole, which is in the shape of a circular platform, and the elastic metal ring 6 is set in the circular groove formed by the grooves 4 to fix the above-mentioned Three press-fit oblique blocks 5 form a tapered press-fit block 3.

[0023] The wires and cables pass through the taper press-fitting block 3. Since the outer diameter of the wires and cables is greater than the diameter of the bottom of the taper press-fitting block 3 and smaller than the diameter of the upper bottom of the taper press-fitting block 3, when the wires and cables pass through the taper press-fitting block 3 , the bottom of the taper press-fitting block 3 will be stretched due to wires and cables, and under the fixing of the elastic metal ring 6, the taper press-fitting block 3 will not be scattered. At this time, put the tapered press-fitting block 3 with wires and cables into...

Embodiment 2

[0025] Four press-fitted inclined blocks 5 with grooves 4 cooperate with each other to form a whole, which is in the shape of a circular platform. The elastic metal ring 6 is set in the circular groove formed by the grooves 4 to fix the above four press-fits. Dress inclined block 5, form taper pressing block 3.

[0026] The wires and cables pass through the taper press-fitting block 3. Since the outer diameter of the wires and cables is greater than the diameter of the bottom of the taper press-fitting block 3 and smaller than the diameter of the upper bottom of the taper press-fitting block 3, when the wires and cables pass through the taper press-fitting block 3 , the bottom of the taper press-fitting block 3 will be stretched due to wires and cables, and under the fixing of the elastic metal ring 6, the taper press-fitting block 3 will not be scattered. At this time, put the tapered press-fitting block 3 with wires and cables into the connecting hole of the terminal body 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com