A hollow fiber carbon molecular sieve membrane and preparation and use thereof

A fiber carbon and molecular sieve technology, which can be used in hollow objects, other household appliances, membranes, etc., and can solve the problems of high capital expenditure and large amount of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

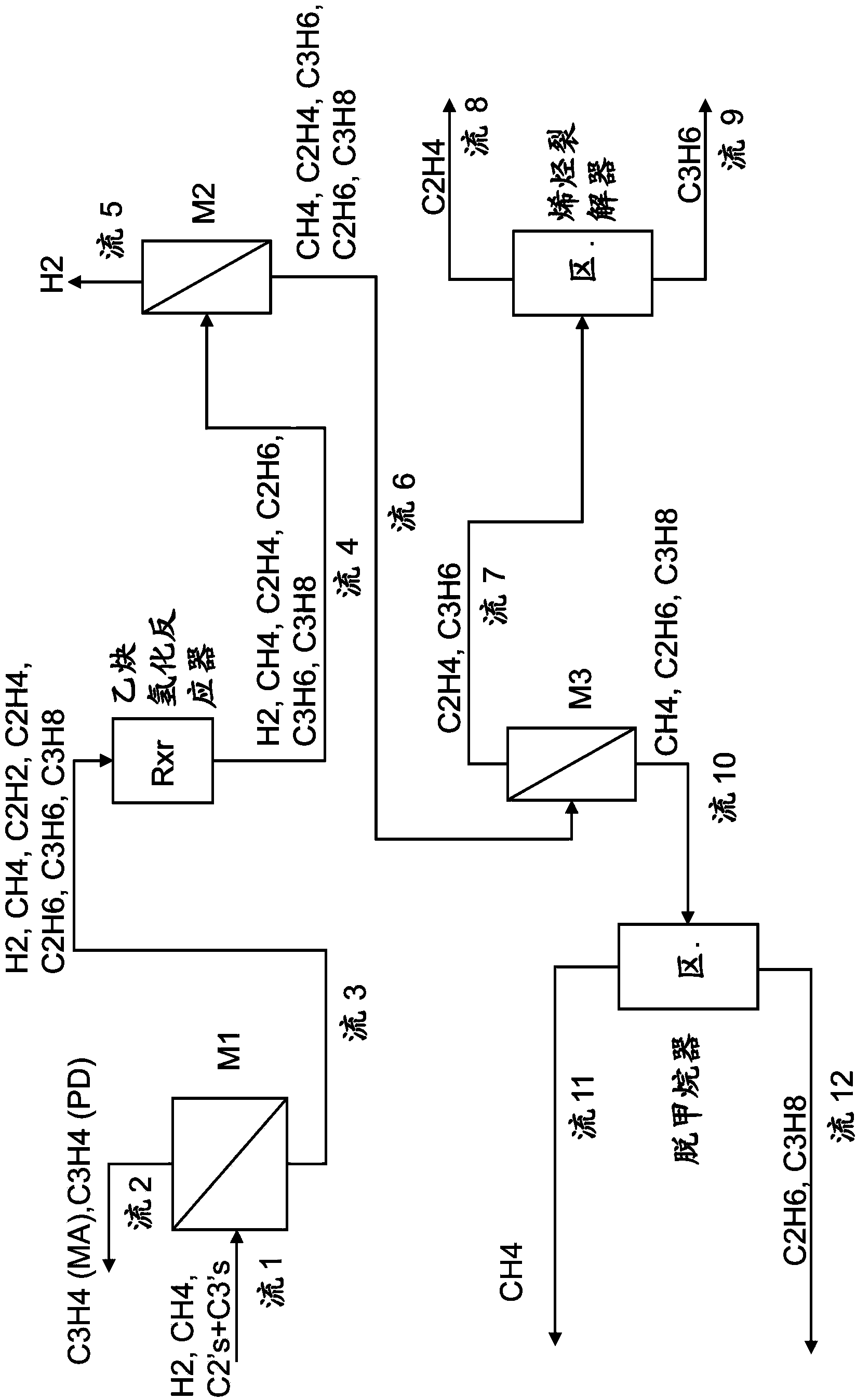

[0023] In some embodiments, the above-described method for effecting the separation of an alkene or at least two alkene from a mixture comprising the one or more alkene and its corresponding alkane is adapted to be suitable for the treatment of the following gaseous mixture, The mixture also comprises at least one additional gaseous component selected from the group consisting of acetylene, hydrogen, propadiene, and methacryne, and said conditions are sufficient to allow at least a portion of said additional gaseous component and at least a portion of said one or Various alkenes pass through the screen while blocking at least a portion of the corresponding alkanes from passing through the screen. A preferred variant of said modified method comprises the additional step wherein the gas passing through said sieve is subjected to a second separation using either the same hollow fiber carbon molecular sieve prepared as described above or a second hollow fiber carbon molecular sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com