Method for producing mold for transferring fine pattern, method for producing substrate having uneven structure using same, and method for producing organic el element having said substrate having uneven structure

A manufacturing method and technology of concave-convex structure, which are applied in the directions of electroluminescent light sources, electrical components, optical components, etc., to achieve the effects of preventing pattern defects, low cost, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

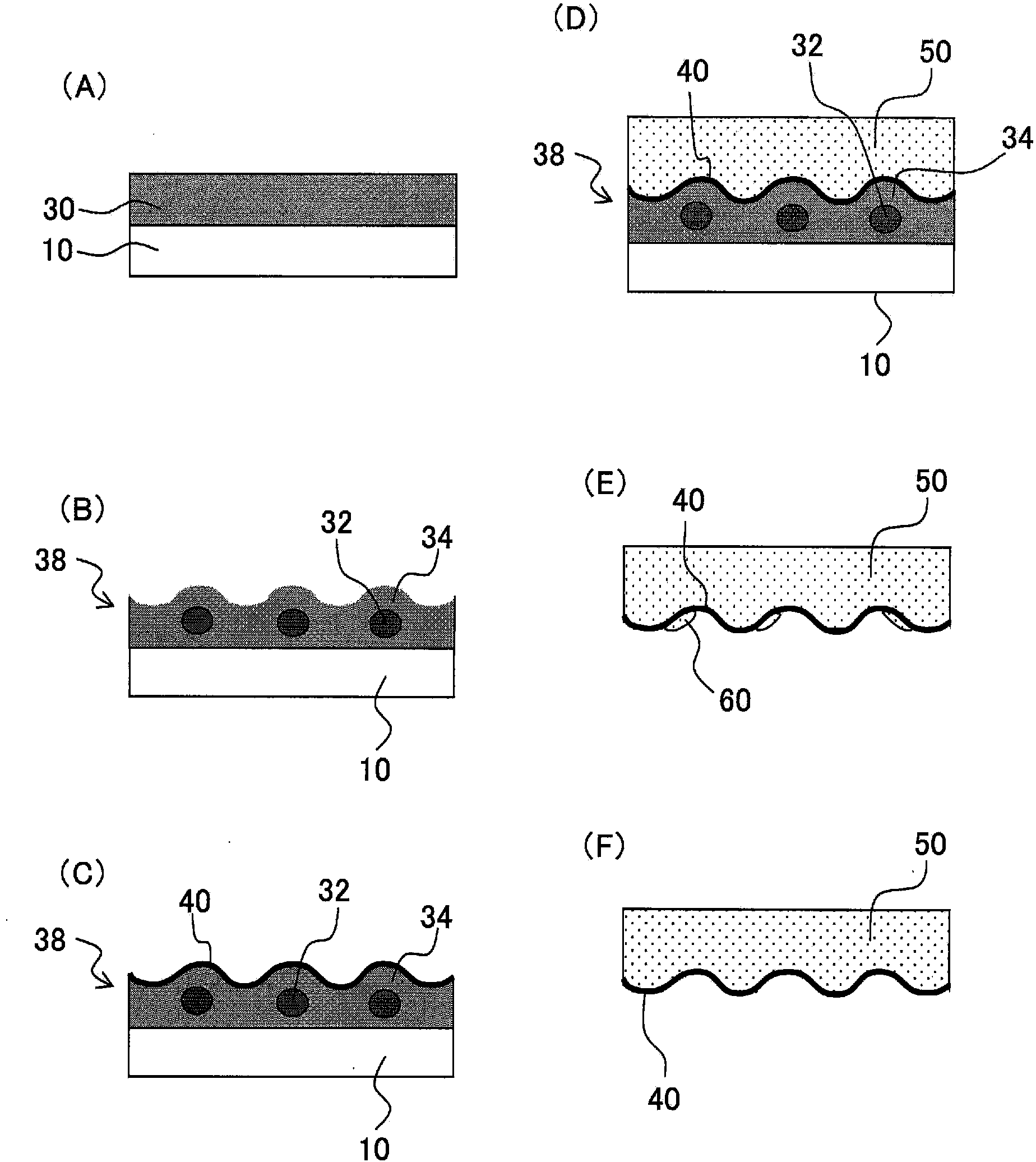

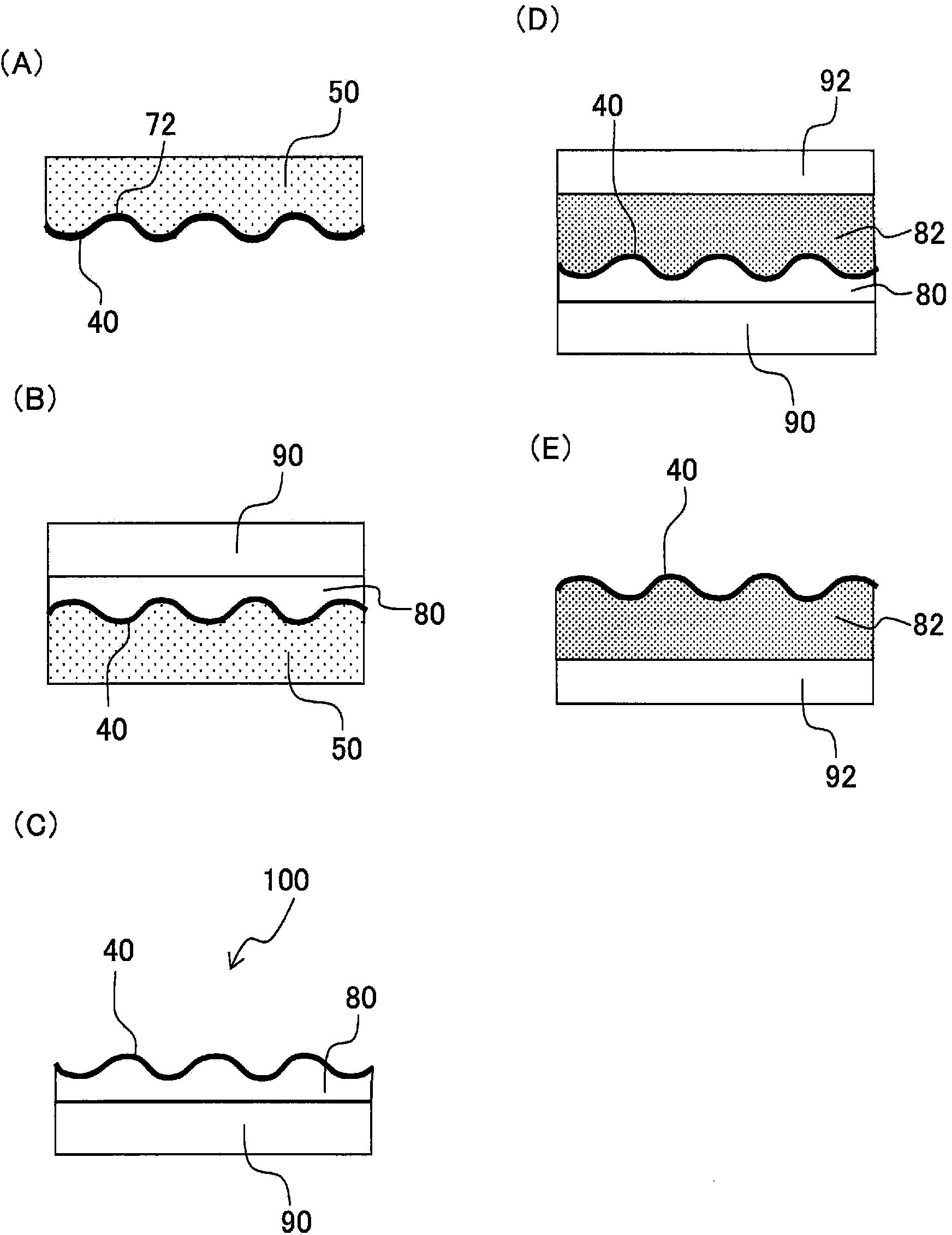

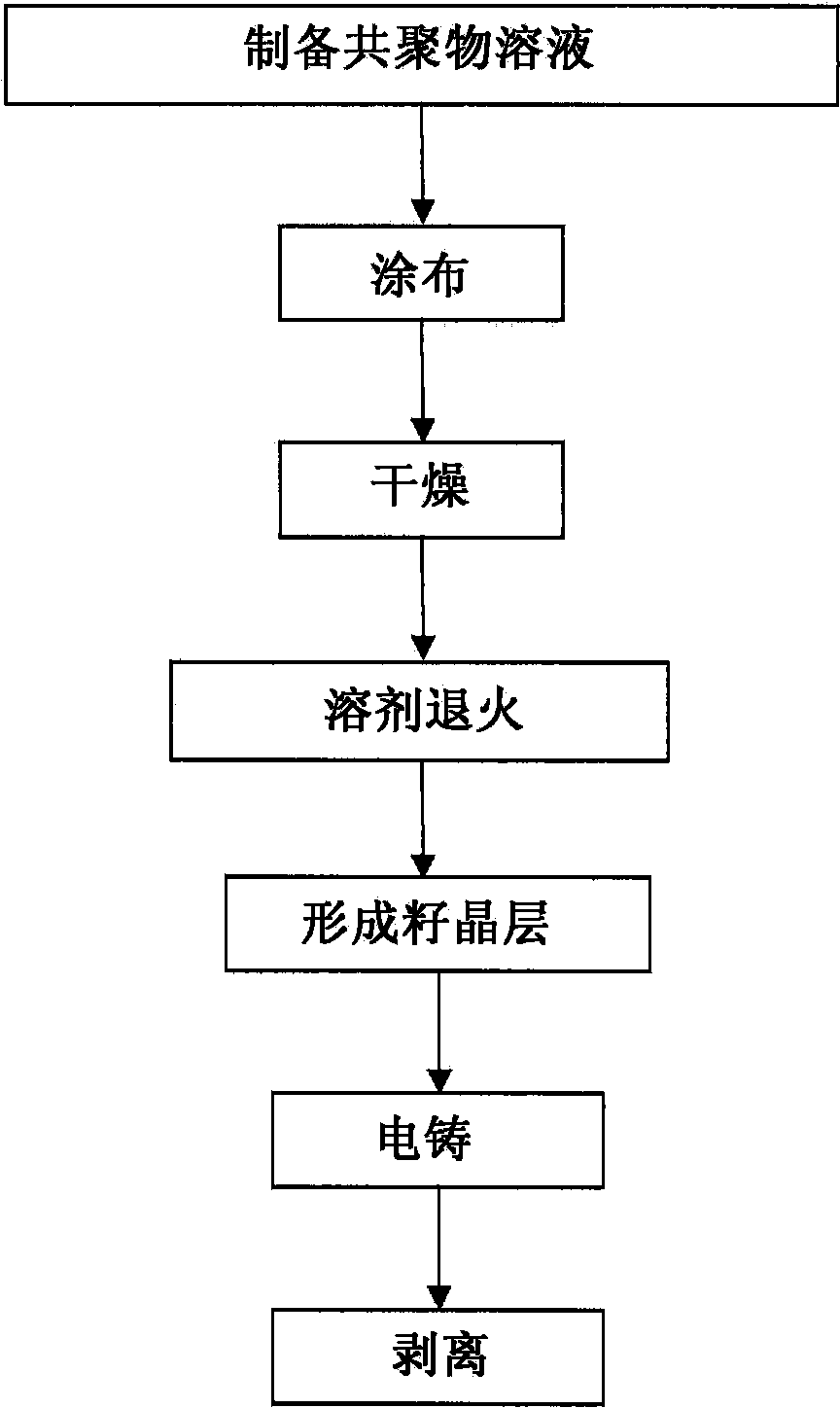

Method used

Image

Examples

preparation example Construction

[0059]

[0060] The block copolymer used in the present invention has at least: a first polymer segment composed of a first homopolymer, and a second polymer segment composed of a second homopolymer different from the first homopolymer . The second homopolymer preferably has a solubility parameter higher than that of the first homopolymer by 0.1 to 10 (cal / cm 3 ) 1 / 2 Solubility parameter. The difference between the solubility parameters of the first homopolymer and the second homopolymer is less than 0.1 (cal / cm 3 ) 1 / 2 , the block copolymer is difficult to form a regular microphase separation structure; the difference exceeds 10 (cal / cm 3 ) 1 / 2 , it is difficult to prepare a homogeneous solution of the block copolymer.

[0061] Examples of monomers that can be used as raw materials for homopolymers used in the first homopolymer and the second homopolymer include styrene, methylstyrene, propylstyrene, butylstyrene, and hexylstyrene. , octylstyrene, methoxystyrene, eth...

Embodiment 1

[0152] Toluene was added to 150 mg of Block Copolymer 1 and 37.5 mg of polyethylene glycol 2050 (average Mn=2050) manufactured by Aldrich as polyethylene oxide so that the total amount was 15 g, and dissolved. Table 1 shows the physical properties of the block copolymer 1 (hereinafter abbreviated as BCP-1 as appropriate).

[0153] This block copolymer solution was filtered with a membrane filter having a pore diameter of 0.5 μm to obtain a block copolymer solution. A mixed solution of KBM-51031 g manufactured by Shin-Etsu Silicone Co., Ltd., 1 g of ion-exchanged water, 0.1 ml of acetic acid, and 19 g of isopropanol was spin-coated on a glass substrate (10 seconds at a rotation speed of 500 rpm, followed by 45 seconds at 800 rpm) . By treating at 130° C. for 15 minutes, a silane coupling-treated glass was obtained. The obtained block copolymer solution was applied by spin coating to a film thickness of 150 to 170 nm on silane coupling-treated glass as a base material. Spin c...

Embodiment 2

[0184] In this example, the number-average molecular weight (Mn) of the block copolymer and the ratio of the PS part and the PMMA part constituting the block copolymer were changed to observe how the concave-convex structure of the film after the solvent annealing treatment changed. As the block copolymer, block copolymers 1 (BCP-1) to 11 (BCP-11) having the physical properties shown in Table 1 were used, except that the amount of polyethylene oxide added relative to 100 mass of the block copolymer Except that the parts were changed to 30 parts by mass, the block copolymer solution was applied and dried on a silane coupling-treated glass substrate in the same manner as in Example 1, and then solvent annealing was performed. The image of the irregularities on the surface of the thin film after the solvent annealing treatment was observed and analyzed by an atomic force microscope under the same analysis conditions as in Example 1. The physical properties of the block copolymers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com