Membrane extraction device and method

An extraction device and extraction technology, which is applied in the field of membrane extraction, can solve the problem that the overall efficiency of membrane extraction is far apart, and achieve the effect of increasing the concentration difference and improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1-membrane extraction experiment

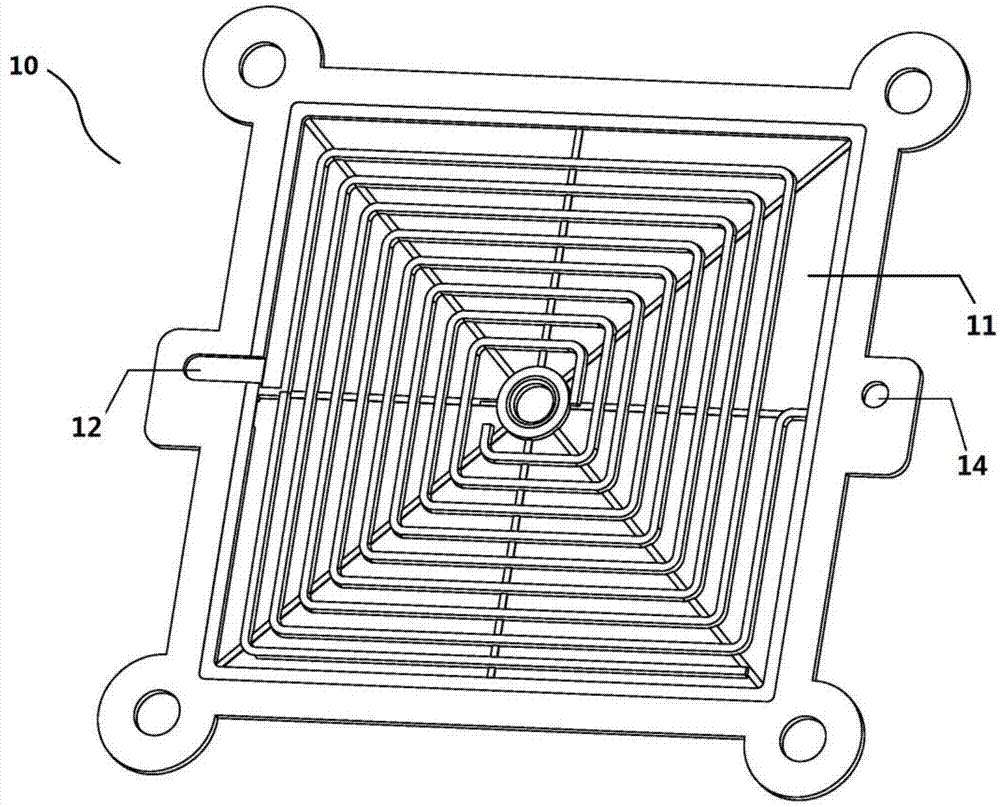

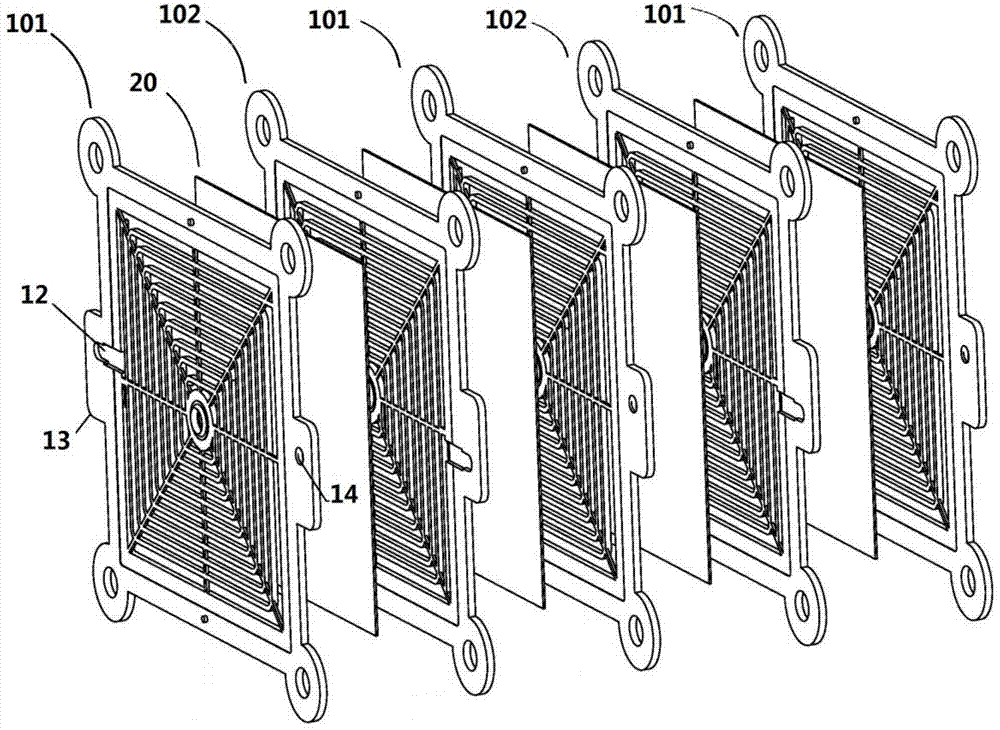

[0051] This embodiment uses the Figure 4 A similar membrane extraction device is shown, except that fifty drain sheets are used. The material of the drainage sheet is polytetrafluoroethylene, the shape is a square of 0.4m×0.4m, the thickness is 5mm, the internal flow channel is rectangular, and the rectangular cross-sectional area is 0.00004m 2 .

[0052] The filter membrane is a special extraction flat membrane produced by Shanghai Jiesheng Environmental Protection Technology Co., Ltd. The filter layer is a cellulose layer, which does not swell in organic solvents, and is a good extraction special membrane material.

[0053] The stock solution uses salt lake brine containing lithium ions, and the ion content in the salt lake brine is as shown in Table 1; 2:6 mass ratio composition.

[0054] Table 1 Table of ion content in raw liquid salt lake brine:

[0055]

[0056] The raw liquid salt lake brine has a density o...

Embodiment 1

[0064] Put the original solution and the extract into the separatory funnel, the original solution is salt lake brine, and the extract is composed of N,N-bis(1-methylheptyl)acetamide / tributyl phosphate / 200 kerosene in a mass ratio of 2:2:6 Composition, stock solution volume is 100ml, extract solution volume is 50ml. After shaking by hand for 20 minutes, let it stand still. After the two solutions are separated, the original solution of salt lake brine is in the lower layer, and the extract is in the upper layer.

Embodiment 2

[0065] Embodiment 2-membrane extraction experiment

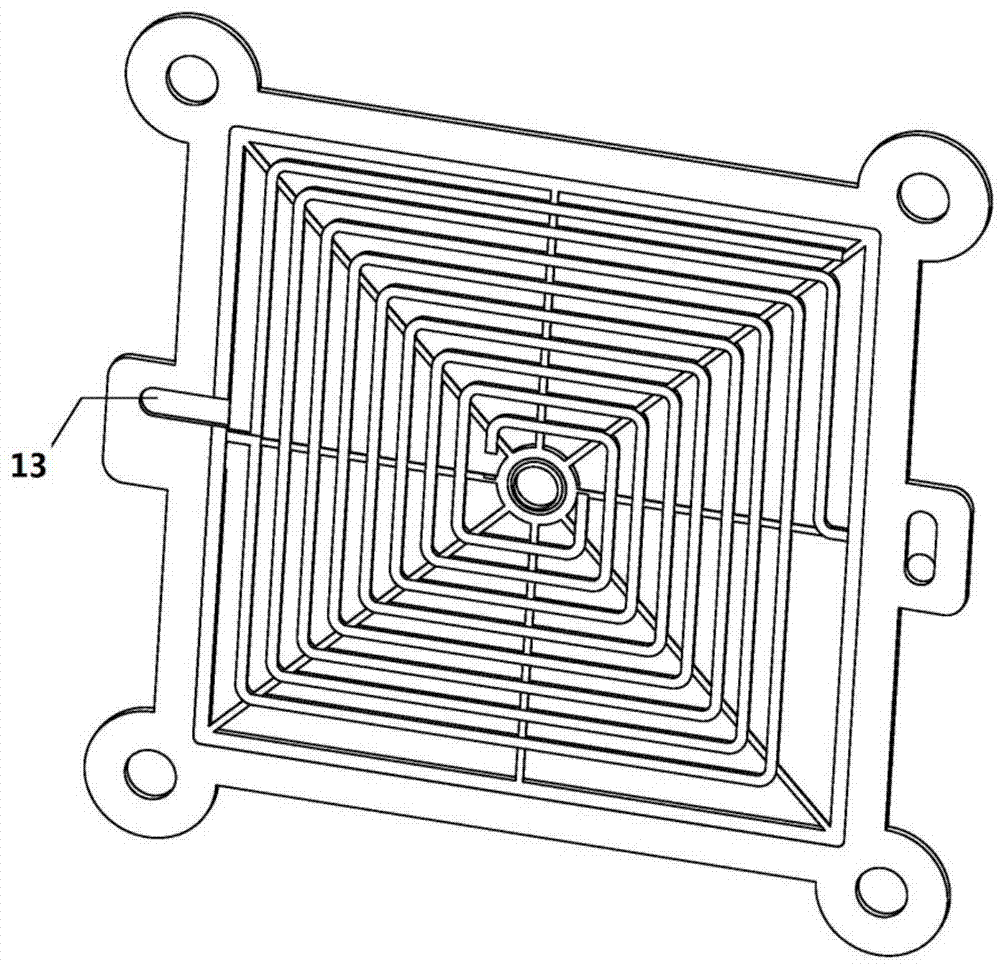

[0066] This embodiment uses the Figure 4 The same membrane extraction device, twenty drainage pieces. The material of the drainage sheet is polyethylene, the shape is a square of 0.5m×0.5m, the thickness is 6mm, the internal flow channel is rectangular, and the rectangular cross-sectional area is 0.00007m 2 .

[0067] The filter membrane is a commercially available PP flat membrane, which does not swell in organic solvents and is a good special membrane material for extraction.

[0068] The stock solution is aqueous acetic acid solution, and the extract solution is methyl isobutyl ketone. The purpose is to extract acetic acid in aqueous solution.

[0069] The raw liquid is pumped into one liquid inlet hole, the extraction liquid is pumped into the other liquid inlet hole, and extracted between the drainage sheet flow channel and the membrane inside the device, the original liquid comes out from one liquid outlet hole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com