Modified biomass charcoal and remediation method of heavy metal contaminated soil

A biomass charcoal and modification technology, which is applied in the restoration of polluted soil, chemical instruments and methods, and other chemical processes, etc., can solve the influence of activated carbon structure and surface functional groups, increase the oxygen content on the surface of activated carbon, and stabilize the efficiency of adsorption of impurities. and other problems, to achieve the effect of enhancing passivation or fixation, repairing or improving soil, and simple modification methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

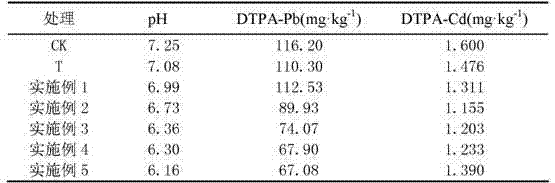

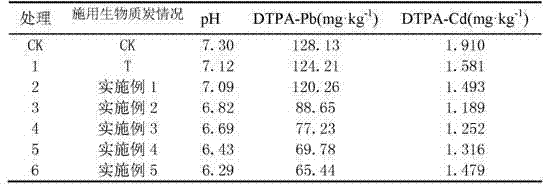

Embodiment 1

[0031] Example 1: A modified biochar suitable for remediation of heavy metal pollution in soil is prepared by the following steps:

[0032] (1) Take corn stalks and peanut shells respectively, wash them with clean water and dry them at 90°C;

[0033] (2) Mix the dried corn stalks and peanut shells at a mass ratio of 1:1, then place them in a muffle furnace for pyrolysis at 600°C for 3 hours, and crush them after cooling;

[0034] (3) After passing the biochar through a 10-mesh sieve, wash it with water to remove floating dust and impurities on its surface until the washing water is neutral;

[0035] (4) Mix the obtained biochar with the phosphoric acid solution at a mass ratio of 1:2, then soak at room temperature for 24 h, and the mass concentration of the phosphoric acid solution is 5%;

[0036] (5) Solid-liquid separation was carried out on the soaking solution, and then the obtained solid material was dried at a constant temperature of 105 °C for 24 h to obtain the modif...

Embodiment 2

[0037] Example 2 : except that the mass concentration of phosphoric acid solution is 10%, it is identical with embodiment 1.

Embodiment 3

[0038] Example 3 : except that the mass concentration of phosphoric acid solution is 15%, it is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com