Internal thread tapping device and control system

The technology of a tapping device and a control system is applied in the field of mechanical processing, which can solve the problems of low processing efficiency, complex structure, long processing time of internal threads, etc., and achieve the effect of improving processing efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] The object of the present invention is to overcome the deficiencies of the prior art, and provide a high-efficiency internal thread tapping device capable of rapidly processing internal threads at one time.

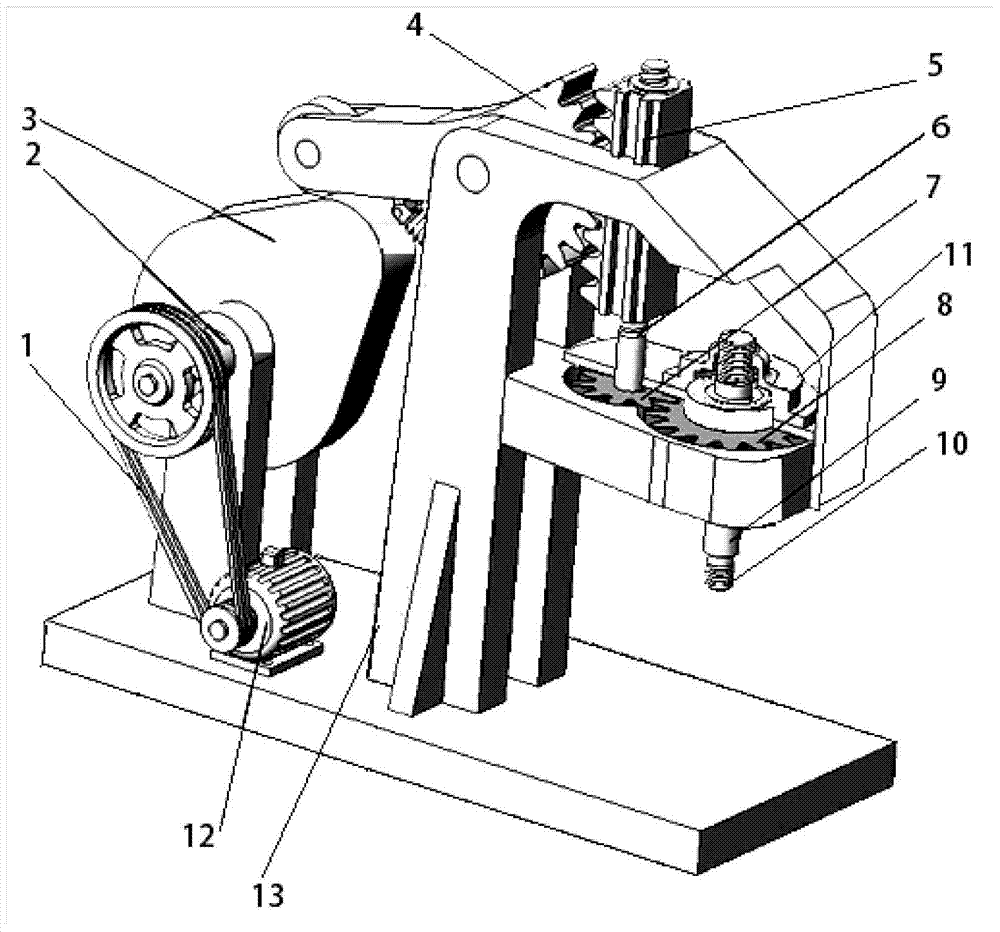

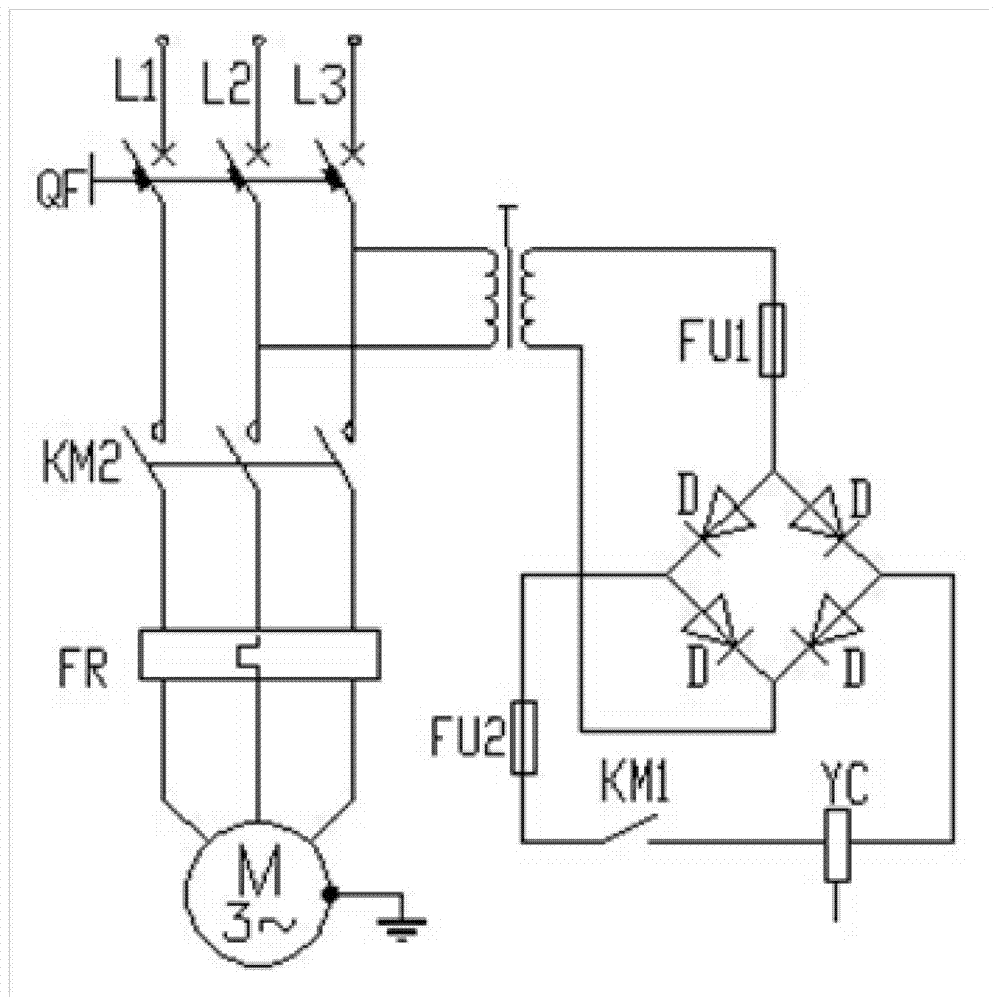

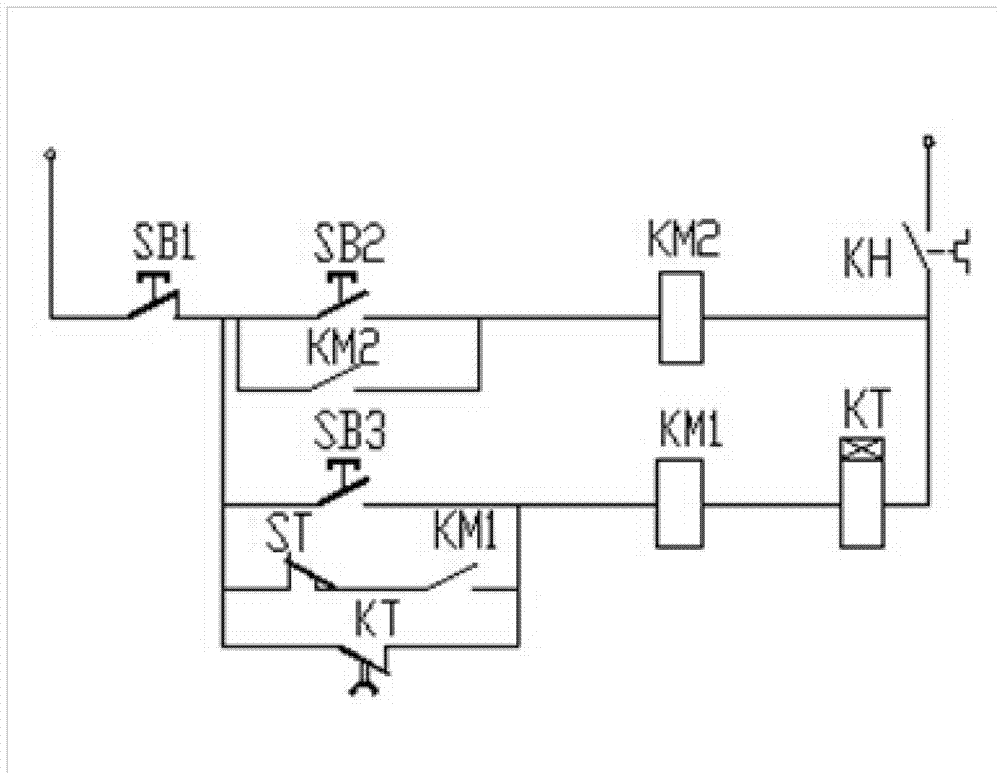

[0015] Such as figure 1 As shown, the motor 12 drives the belt transmission 1 to move, the large pulley shaft of the belt transmission 1 is connected with the cam 3 shaft through the electromagnetic clutch 2, the cam 3 is rotatably hinged on the frame 13, and the tail of the sector gear 4 is flexibly connected with the cam 3, Composed of a high pair, the middle part of the sector gear 4 is rotatably hinged on the frame 13. When the cam 3 rotates, it can drive the sector gear 4 to perform swinging motion with the hinge of the sector gear 4 middle part and the frame 13 as the axis. The head of the sector gear 4 The teeth of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com