Vertical double-station steel pipe fittings rotary automatic welding machine

An automatic welding, double-station technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of improving welding quality, reducing welding noise pollution, and uniform welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments.

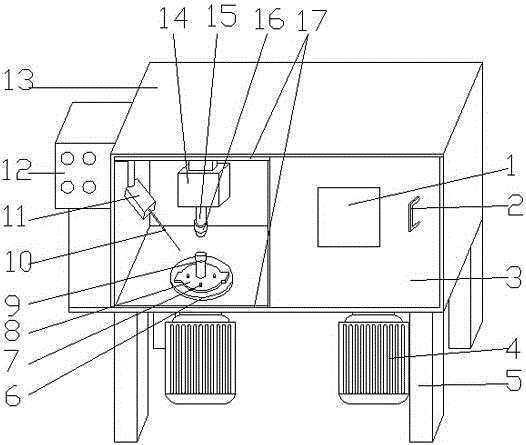

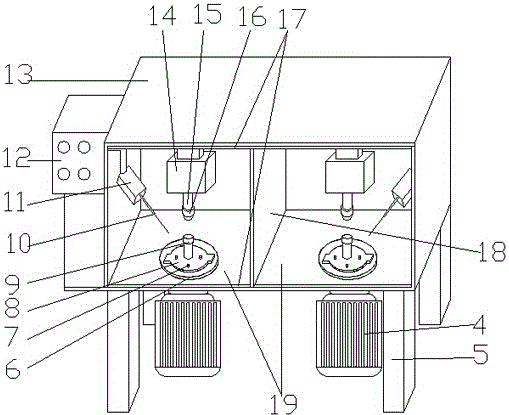

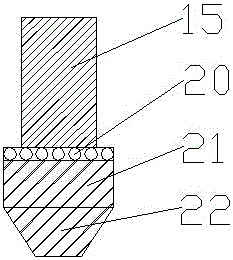

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a vertical double-station steel pipe fitting rotary automatic welding machine includes a bed 13, an automatic welding device, and an electrical control device 12. The bed 13 includes pillars 5 fixed at its four corners and two identical welding Chamber 19 adopts a double-station welding method, which greatly improves production efficiency and is suitable for large-scale production; the welding chamber 19 is symmetrically arranged at both ends of the bed 13 with the isolation plate 18 as the center, and the welding chamber 19 The same automatic welding device is respectively provided; the automatic welding device includes a welding device, a vertical correction fastening device and a rotary device, and the welding device includes a welding wire feeding device 11 and a welding torch arranged on the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com