Recovering and purifying device and recovering method of thionyl chloride in acyl chloride production

A thionyl chloride, purification device technology, applied in the direction of thionyl chloride, sulfur and halogen compounds, etc., can solve the problems of production capacity control, increase recycling cost, unsuitable for popularization and use, etc., achieve effective separation, realize automatic control, Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

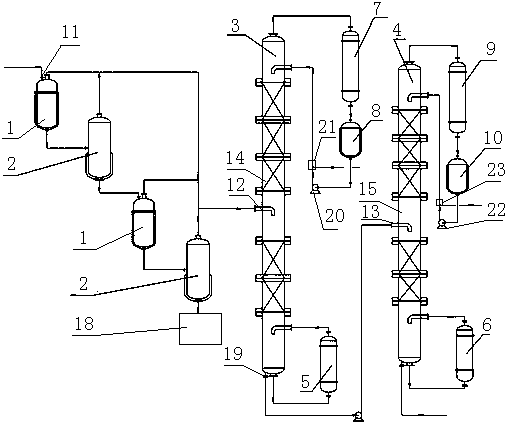

[0021] A recovery and purification device for thionyl chloride in the production of acyl chlorides of this embodiment, refer to the attached figure 1 , including an evaporating device, a thionyl chloride delightening tower 3, and a thionyl chloride refining tower 4 connected in series, the evaporating device is provided with an acid chloride synthesis liquid inlet 11, and the thionyl chloride delightening tower 3 is provided with a chlorination Thionoxide crude product inlet 12 and heavy component discharge port 19, Thionyl chloride refining tower 4 is provided with heavy component inlet 13, evaporation device is connected with thionyl chloride crude product inlet 12 through pipeline, heavy component discharge port 19 is communicated with the heavy component inlet 13 through a pipeline; the delightening tower 3 of the sulfur oxychloride includes a delightening tower heating device 5 assembled and connected sequentially from bottom to top, a thionyl chloride rectifying tower I14...

Embodiment 2

[0024] The recovery purification method of thionyl chloride in the production of isophthaloyl chloride of the present embodiment is as follows:

[0025] Among them, the synthetic liquid of isophthaloyl dichloride includes: 75% of isophthaloyl dichloride, 23% of thionyl chloride, and 2% of other components.

[0026] The synthesis liquid of isophthaloyl chloride enters the two-stage evaporation unit connected in series, the temperature of the evaporation tank in the evaporation device is controlled to 100°C, and the pressure of the separation tank is 30KPa. Since the boiling point of thionyl chloride is lower than that of acid chloride, the separation of the two is realized. The thionyl chloride vapor phase enters the thionyl chloride light removal tower 3, and the isophthaloyl chloride synthesis liquid from which the thionyl chloride is removed enters the acyl chloride continuous rectification system 18. Ceramic corrugated packing is housed in the light removal tower 3 of thion...

Embodiment 3

[0028] The recovery and purification method of thionyl chloride in the production of terephthaloyl chloride of the present embodiment is as follows:

[0029] Among them, the synthetic solution of terephthaloyl dichloride includes: 70% of isophthaloyl dichloride, 28% of thionyl chloride, and 2% of other components.

[0030] The terephthaloyl chloride synthetic liquid enters the two-stage evaporation unit connected in series, and the temperature of the evaporation tank in the evaporation device is controlled to 110°C, and the pressure of the separation tank is 20KPa. Since the boiling point of thionyl chloride is lower than that of acid chloride, the separation of the two is realized. The thionyl chloride vapor phase enters the thionyl chloride light removal tower 3, and the isophthaloyl chloride synthesis liquid from which the thionyl chloride is removed enters the acyl chloride continuous rectification system 18. Ceramic corrugated packing is housed in the light removal tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com