Method for preparing off-white attapulgite by hydrothermal method

A technology of attapulgite and attapulgite clay, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of protein denaturation, vascular toxicity, liver and kidney toxicity, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

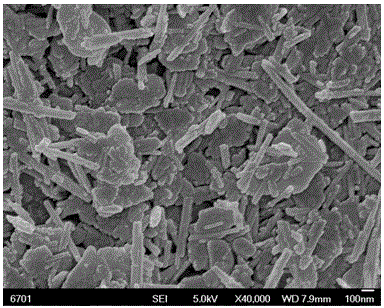

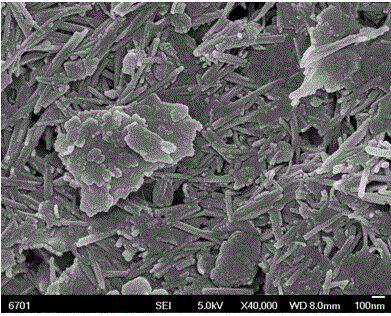

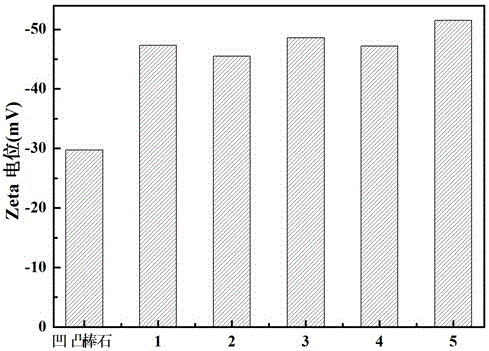

[0021] Under stirring conditions, disperse 0.6g sulfuric acid and 0.3g sodium sulfide in 600 mL water, add 8g brick red attapulgite clay and stir for 1 hour to disperse evenly, then place it in a 1 L autoclave and react at a temperature of 180 °C After 48 h, the temperature was naturally cooled to room temperature, centrifuged and washed with tap water, dried, crushed, and passed through a 200-mesh sieve to obtain a reddish attapulgite. The attapulgite has an adsorption capacity of 105 mg / g for heavy metal copper ions.

Embodiment 2

[0023] Under stirring conditions, disperse 1.5g aminoacetic acid and 0.5g zinc sulfide in 600 mL water, add 10g brick red attapulgite clay and stir for 1 hour to disperse evenly, then place it in a 1 L autoclave, at a temperature of 220 ℃ After reacting for 48 h, cool down to room temperature naturally, centrifuge, wash with tap water, dry and pulverize. Pass through a 200-mesh sieve to obtain off-white attapulgite. The attapulgite has an adsorption capacity of 108 mg / g for heavy metal copper ions.

Embodiment 3

[0025] Under stirring conditions, disperse 1.5g acetic acid and 0.8g ammonium sulfide in 600 mL water, add 15g brick red attapulgite clay and stir for 1 hour to disperse evenly, then place it in a 1 L autoclave and react at a temperature of 200 °C After 72 hours, the temperature was naturally cooled to room temperature, centrifuged, washed with tap water, dried, crushed, and passed through a 200-mesh sieve to obtain off-white attapulgite. The attapulgite has an adsorption capacity of 112 mg / g for heavy metal copper ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com