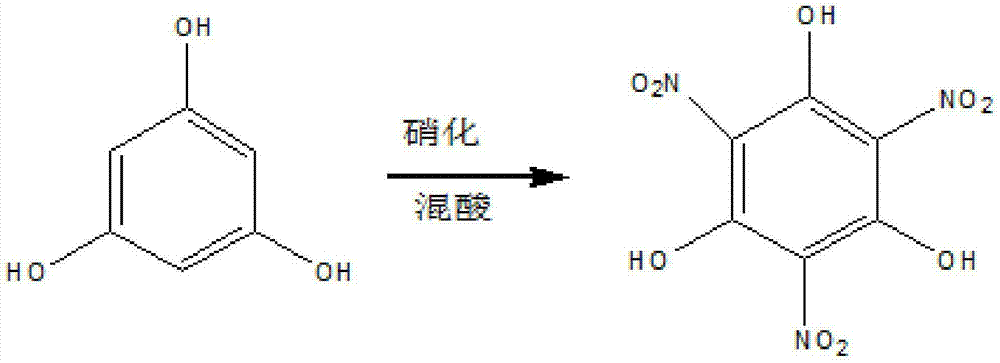

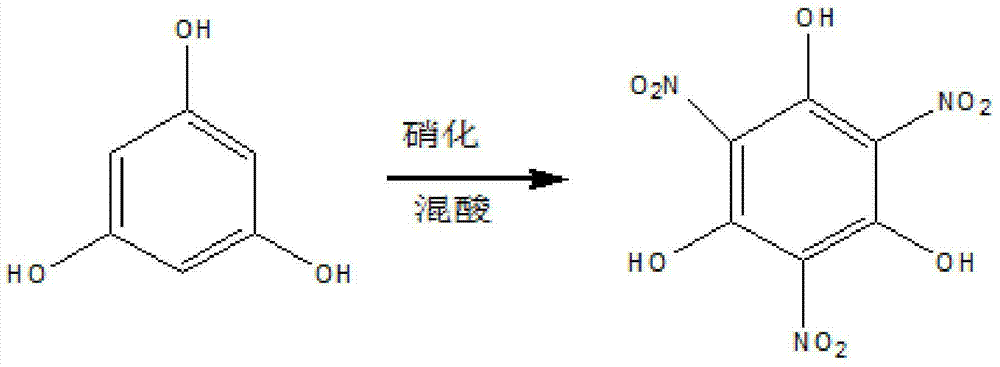

Treatment method of nitration wastewater in TATB (triamino trinitrobenzene) production technique

A technology of nitrification wastewater and treatment method, which is applied in the fields of natural water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of non-selectivity, no economical and effective method for nitrification wastewater, etc., and achieves short treatment time. , Simple operation, high COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

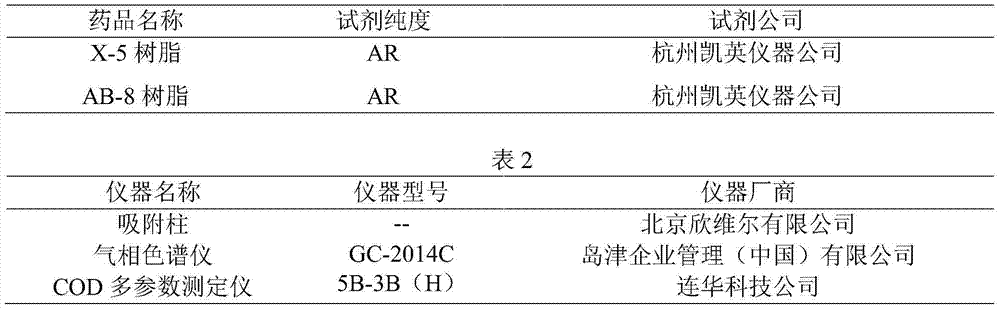

[0033] (1) Filtration: filter the wastewater produced by the TATB nitrification reaction, collect the precipitate, wash to obtain nitrification wastewater; the pH of the nitrification wastewater is <0, the COD value is 672.7mg / L, and the phloroglucinol content is 0.73mg / ml;

[0034] (2) Adsorption: At 30°C, take 20ml (wet volume) X-5 resin and evenly fill it in the adsorption column In the process, 100ml of nitrification wastewater was added to the adsorption column filled with X-5 resin, and the wastewater was flowed through the adsorption column at a speed of 1BV / h, and the colorless effluent was collected. The COD value was 80.5mg / L, and the COD removal rate reached 88.03 %.

[0035] (3) Desorption: The X-5 resin after adsorption treatment is eluted with methanol, wherein the elution temperature is 40°C; the eluate after methanol elution is distilled to recover methanol, and the residue is incinerated; The adsorption column was washed with hot water and reused.

Embodiment 2

[0037] (1) Filtration: filter the wastewater produced by the TATB nitrification reaction, collect the precipitate, wash to obtain nitrification wastewater; the pH of the nitrification wastewater is <0, the COD value is 672.7mg / L, and the phloroglucinol content is 0.73mg / ml;

[0038] (2) Adsorption: At 40°C, take 100ml (wet volume) X-5 resin and evenly fill it in the adsorption column In the process, 100ml of nitrification wastewater was added to the adsorption column filled with X-5 resin, and the wastewater flowed through the adsorption column at a speed of 3BV / h, and the colorless effluent was collected. The COD value was 79.76mg / L, and the COD removal rate reached 88.14 %.

[0039] (3) Desorption: The X-5 resin after adsorption treatment is eluted with methanol, wherein the elution temperature is 60°C; the eluate after methanol elution is distilled to recover methanol, and the residue is incinerated; The adsorption column was washed with hot water and reused.

Embodiment 3

[0041] (1) Filtration: filter the wastewater produced by the TATB nitrification reaction, collect the precipitate, wash to obtain nitrification wastewater; the pH of the nitrification wastewater is <0, the COD value is 672.7mg / L, and the phloroglucinol content is 0.73mg / ml;

[0042] (2) Adsorption: At 15°C, take 20ml (wet volume) X-5 resin and evenly fill it in the adsorption column In the process, 100ml of nitrification wastewater was added to the adsorption column filled with X-5 resin, and the wastewater was flowed through the adsorption column at a speed of 5BV / h, and the colorless effluent was collected. The COD value was 84.5mg / L, and the COD removal rate reached 87.44 %.

[0043] (3) Desorption: The X-5 resin after adsorption treatment is eluted with methanol, wherein the elution temperature is 45°C; the eluate after methanol elution is distilled to recover methanol, and the residue is incinerated; The adsorption column was washed with hot water and reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com