Nano far infrared negative ion pigment printing paste and preparation method thereof

A far-infrared negative ion and paint printing technology, applied in the field of textiles, can solve the problems of weak binding of negative ions, easy to fall off, loss of function, etc., and achieve the effects of improving human immunity, promoting blood circulation, and improving air quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

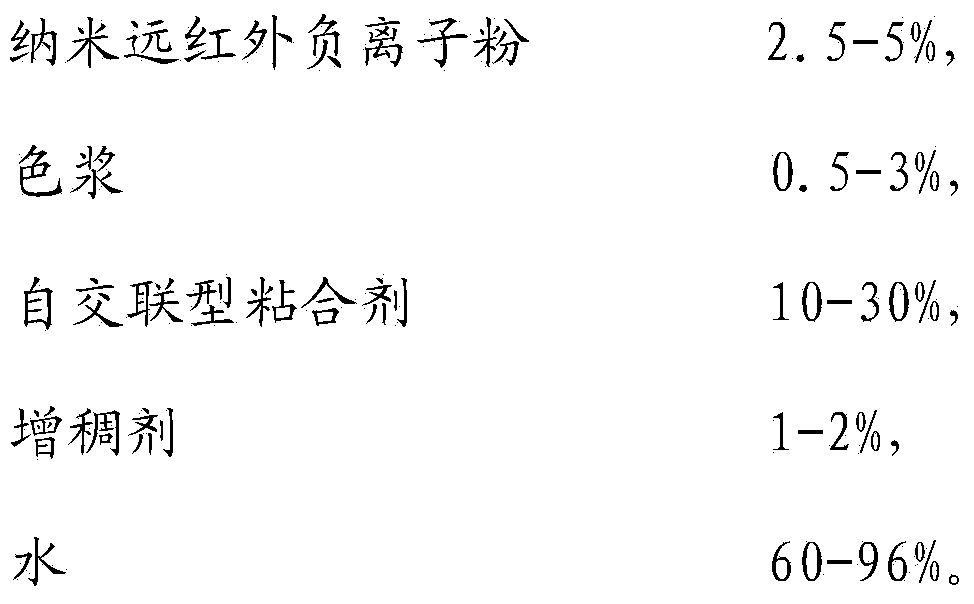

[0022] A kind of nanometer far-infrared negative ion pigment printing paste, comprises the following components by mass percentage:

[0023]

[0024] The self-crosslinking adhesive is a methacrylic paint adhesive.

[0025] The preparation method of described nanometer far-infrared negative ion paint printing paste, comprises the steps:

[0026] 1) Measure nanometer far-infrared negative ion powder, adhesive, thickener, color paste and water according to the formula;

[0027] 2) Preparation of nanometer far-infrared negative ion slurry: mix nanometer far-infrared negative ion powder with water at a mass ratio of 1:3; first stir at 800rpm for 8 minutes, then stir at 2500rpm for 18 minutes at high speed, filter it with a 100-mesh filter bag, and finally Then use a 190 mesh filter bag to filter and set aside;

[0028] 3) Mix the adhesive, thickener, color paste, and water evenly, add the nanometer far-infrared anion paste prepared in step 1) of 15% of the total mass of the pi...

Embodiment 2

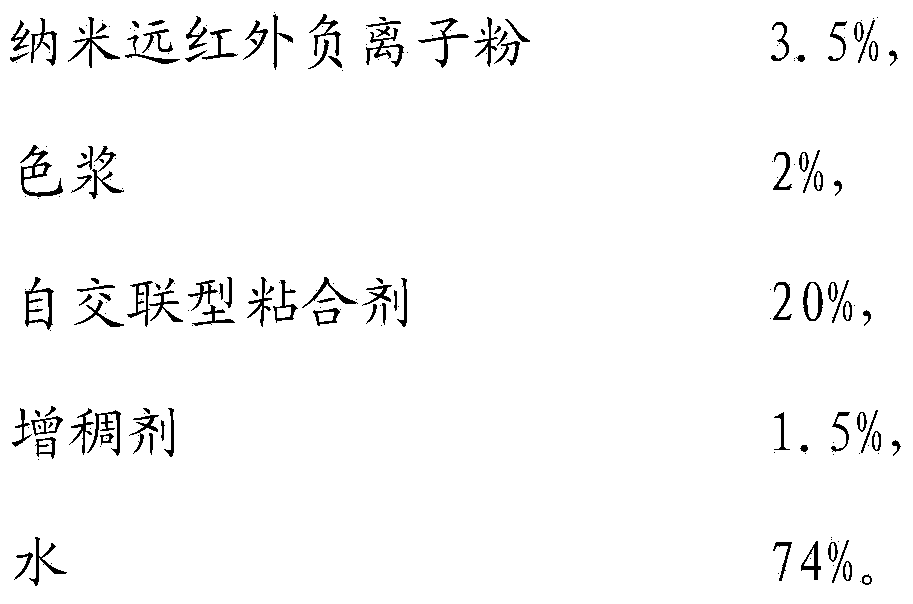

[0031] A kind of nanometer far-infrared negative ion pigment printing paste, comprises the following components by mass percentage:

[0032]

[0033] The self-crosslinking adhesive is a polyurethane coating adhesive.

[0034] The preparation method of described nanometer far-infrared negative ion paint printing paste, comprises the steps:

[0035] 1) Measure nanometer far-infrared negative ion powder, adhesive, thickener, color paste and water according to the formula;

[0036] 2) Preparation of nanometer far-infrared negative ion slurry: Mix nanometer far-infrared negative ion powder with water at a mass ratio of 1:3; first stir at 500rpm for 10 minutes, then stir at 3000rpm for 15 minutes at high speed, filter it with an 80-mesh filter bag, and finally Then use a 200-mesh filter bag to filter and set aside

[0037] 3) Mix the binder, thickener, color paste and water evenly, add the nanometer far-infrared anion paste prepared in the step 1) of 10-20% of the total mass of...

Embodiment 3

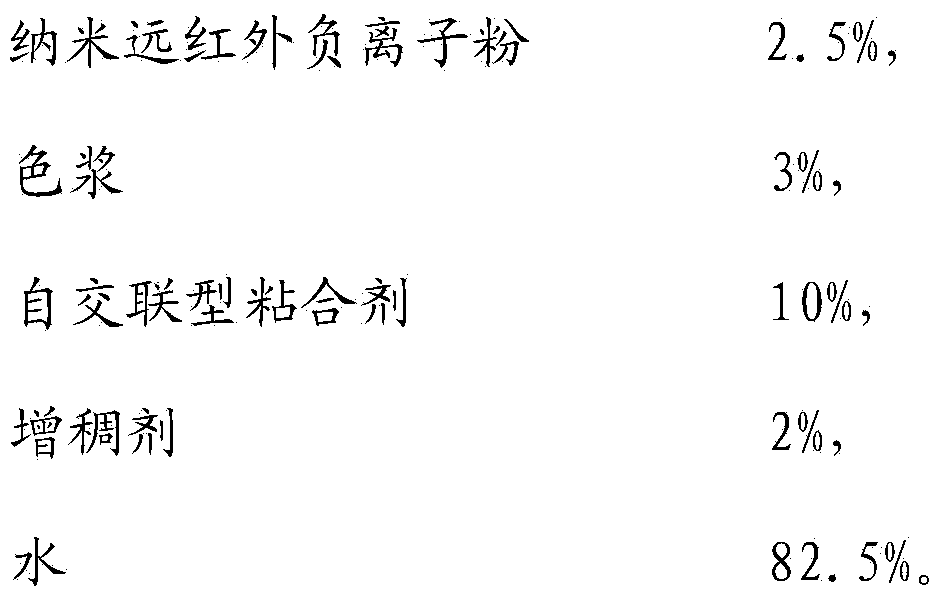

[0040] A kind of nanometer far-infrared negative ion pigment printing paste, comprises the following components by mass percentage:

[0041]

[0042] The self-crosslinking adhesive is a methacrylic paint adhesive.

[0043] The preparation method of described nanometer far-infrared negative ion paint printing paste, comprises the steps:

[0044] 1) Measure nanometer far-infrared negative ion powder, adhesive, thickener, color paste and water according to the formula;

[0045] 2) Preparation of nano-far-infrared negative ion slurry: Mix nano-far-infrared negative ion powder with water at a mass ratio of 1:3; first stir at 1000rpm for 10 minutes, then stir at 2000rpm for 15 minutes at high speed, filter it with a 120-mesh filter bag, and finally Then use a 180-mesh filter bag to filter and set aside

[0046] 3) Mix the binder, thickener, color paste, and water evenly, add the nanometer far-infrared anion paste prepared in step 1) of 10% of the total mass of the pigment print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com