A wide-band infrared scanning spectroscopic device and calibration method

An infrared scanning and spectroscopic device technology, which is applied in the field of infrared radiation spectroscopic testing, can solve the problems of high cost, difficult CVF device coating technology, and difficulty in universal adoption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

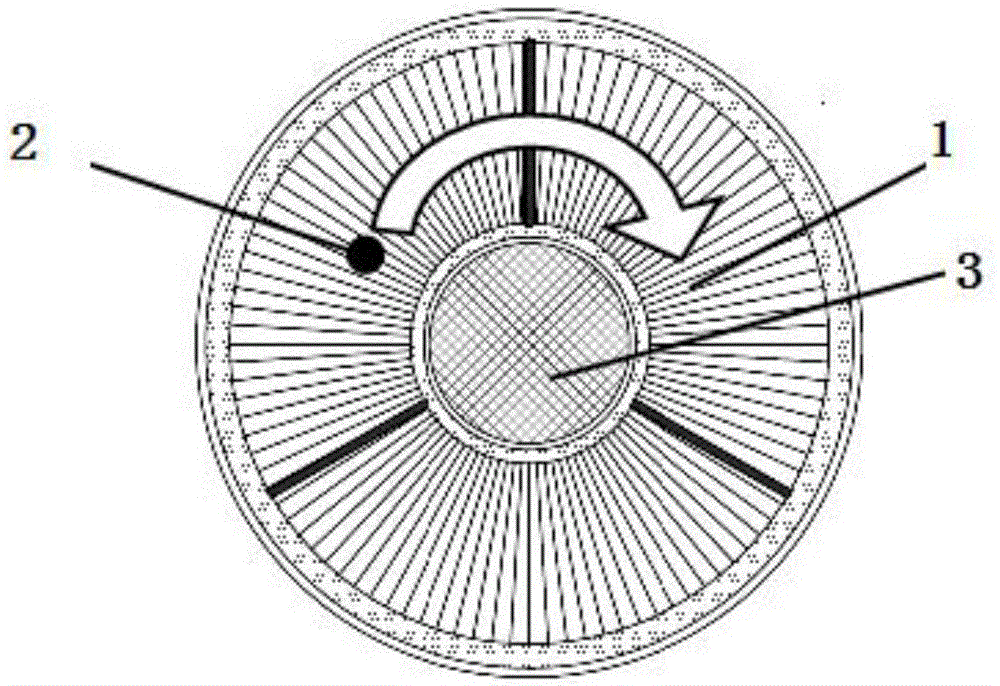

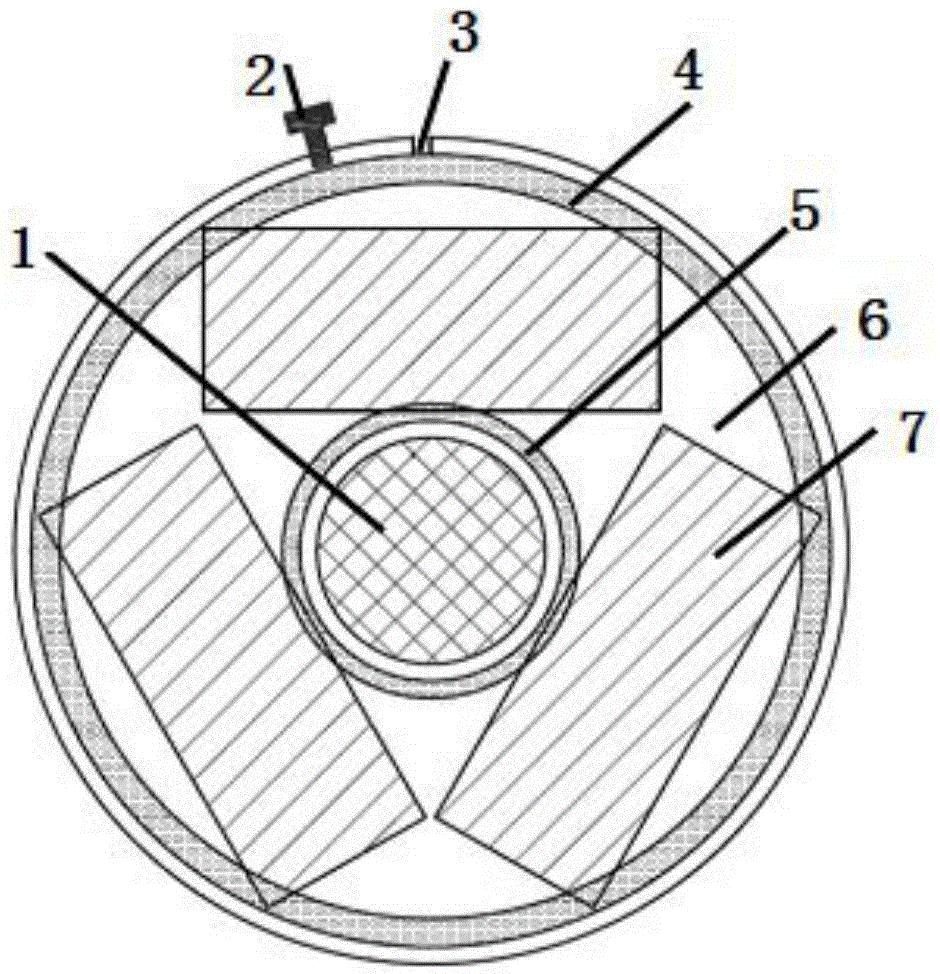

[0031] The present invention designs a device that uses multi-chip combined LVF (strip-shaped gradient filter) for infrared spectrum radiation splitting and can perform high-speed scanning. Such as figure 2 As shown, the device of the present invention includes LVF7, fixture 6, driving motor 1, photoelectric switch 2, zero opening 3, outer pressure ring 4 and inner pressure ring 5, and the driving motor 1 drives the fixture 6 equipped with LVF7 to perform a rotation scanning test. The inner pressure ring 5 and the outer pressure ring 4 just press the non-working area of the LVF7 for fixing, the assembly is simple and firm, and high-speed rotating scanning test can be realized.

[0032] During the test, the light spot converged by the incident lens is hit on the LVF7, and the fixture 6 equipped with the LVF7 is rotated under the drive of the drive motor 1, and the transmitted radiation is detected by an infrared detector, and the scanning is completed with the rotation of th...

Embodiment 2

[0034] On the basis of the above embodiments, the present invention also provides a calibration method for a broadband infrared scanning spectroscopic device,

[0035] Compared with using CVF for scanning and splitting, the present invention greatly reduces the difficulty of coating technology and the cost of coating. Aiming at the wavelength inhomogeneity in the LVF scanning process, a corresponding wavelength calibration algorithm is designed to realize continuous scanning of wide infrared band spectral radiation.

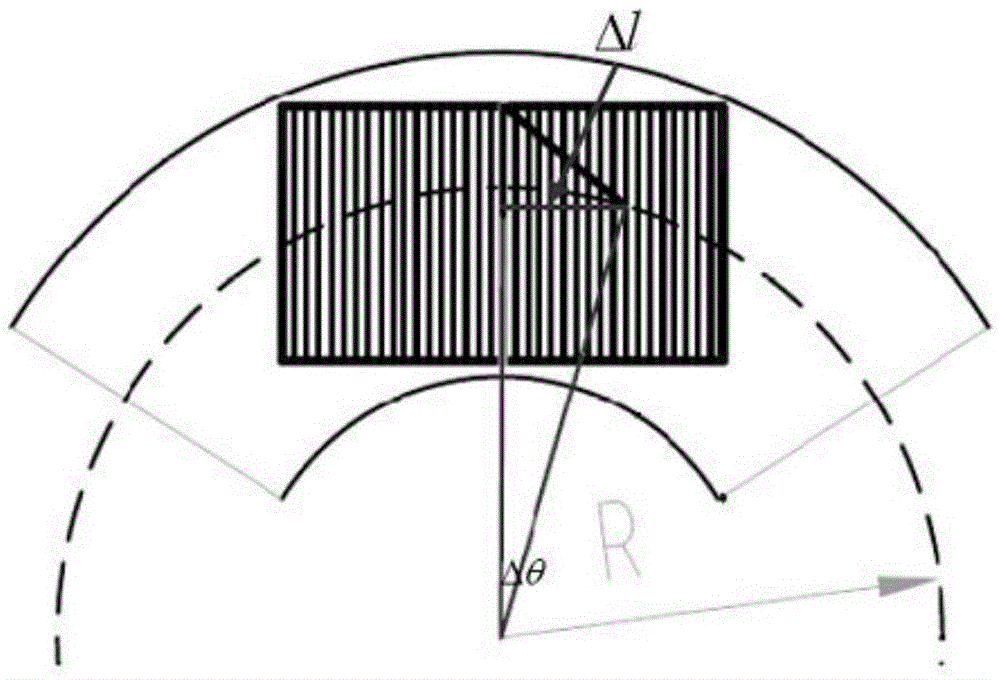

[0036] Since the use of LVF for light splitting is not as uniform as CVF, there will be invalid data in the test using the above device. For this, a corresponding wavelength calibration method using the above device is designed to establish the corresponding relationship between wavelength and intensity. In order to achieve wide Continuous testing of spectral radiation in the infrared band, such as image 3 Shown:

[0037] Since the filter is scanned at a unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com