Method for detecting valve air tightness through high-flow high-voltage gas source

A high-pressure gas source and high-flow technology is applied in the direction of measuring the increase and deceleration rate of the fluid, and using liquid/vacuum degree to measure the liquid tightness, etc. It can solve the problems of low efficiency, long time, small gas flow, etc., to achieve Effects of ensuring safety, improving gas flow rate, and expanding detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

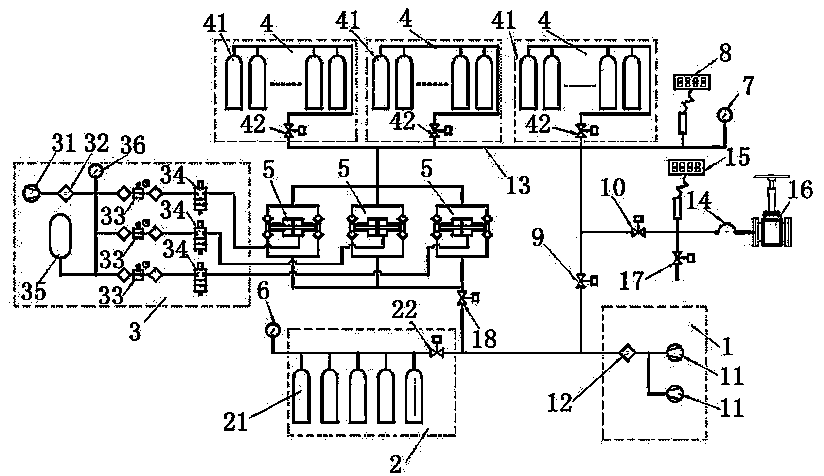

[0018] This embodiment is a method for detecting the air tightness of a valve with a high-flow high-pressure air source. The method uses a high-flow high-pressure air source system to detect the air tightness of the valve. The high-flow high-pressure air source system includes: a high-pressure air compressor ( 1) and high-pressure gas purification device (11) composed of gas supply source, working gas source, pipeline and control valve connected to the valve to be tested (16), pressure sensor (8) for detecting system status, pressure gauge (6 ) and high-pressure gauges (7), pressure sensors for detecting the status of the valves to be tested (16), pressure gauges and digital displays, and the working gas sources include ordinary high-pressure bottle sets (2) and higher high-pressure bottle sets (4) , between the ordinary high-pressure bottle group (2) and the higher high-pressure bottle group (4), there is a gas-gas booster assembly connected through pipelines, and the high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com