Method for testing skip change of worm wheel and worm fit friction coefficient of automobile steering system

An automotive steering system and worm gear technology, applied in the automotive field, can solve problems such as affecting corporate profits, declining vehicle sales, and lack of lubrication, improving customer satisfaction, reducing costs and cycles, and achieving simple and practical methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and relevant content, the present invention will be further described:

[0026] Through the description of the embodiments, the specific implementation of the present invention, such as the mutual position and connection relationship between the various parts involved, is further described in detail, so as to help those skilled in the art to implement the concept of the present invention and technical solutions Have a more complete, accurate and in-depth understanding.

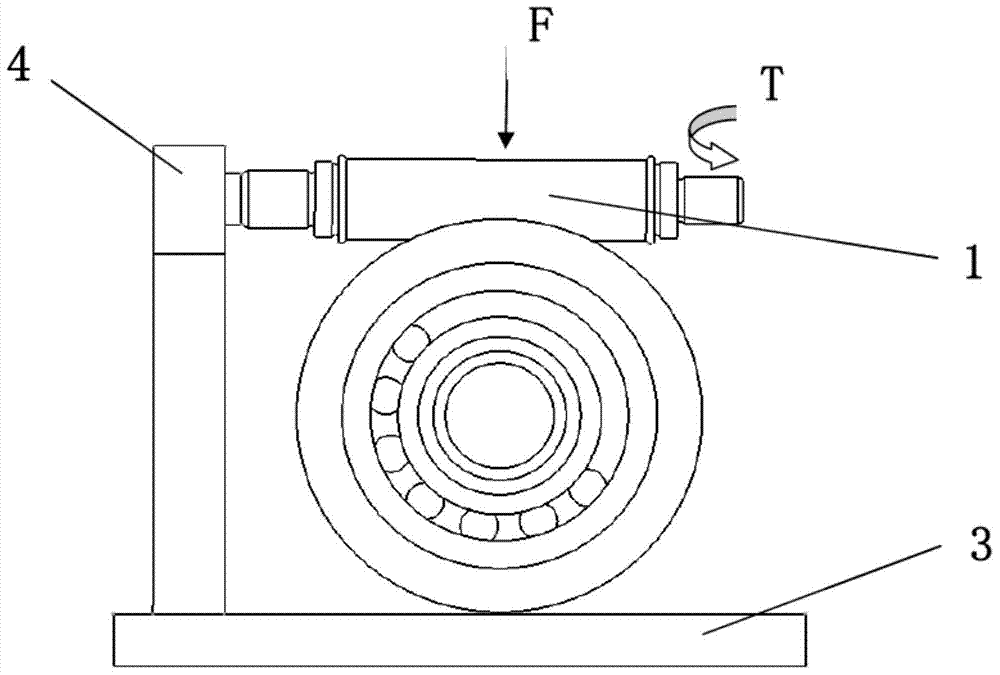

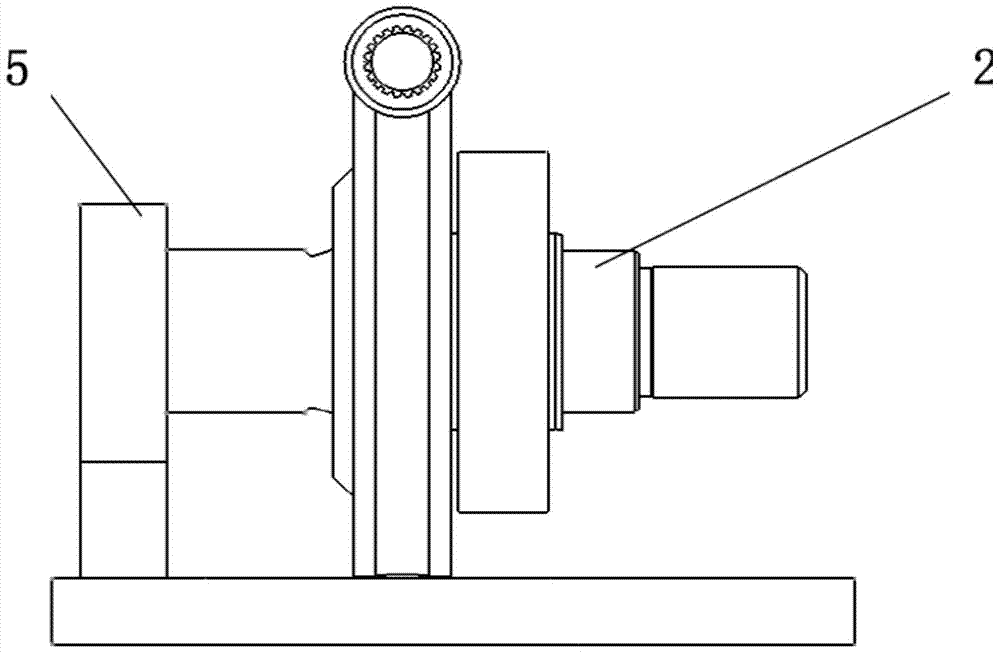

[0027] Such as figure 1 , figure 2 As shown, for the cooperation relationship between the parts worm assembly 1 and worm gear assembly 2 of the deceleration mechanism of the column type electric steering system, the friction coefficient of the mating surface can be measured through the present invention, and the beating variation of the friction coefficient can be measured .

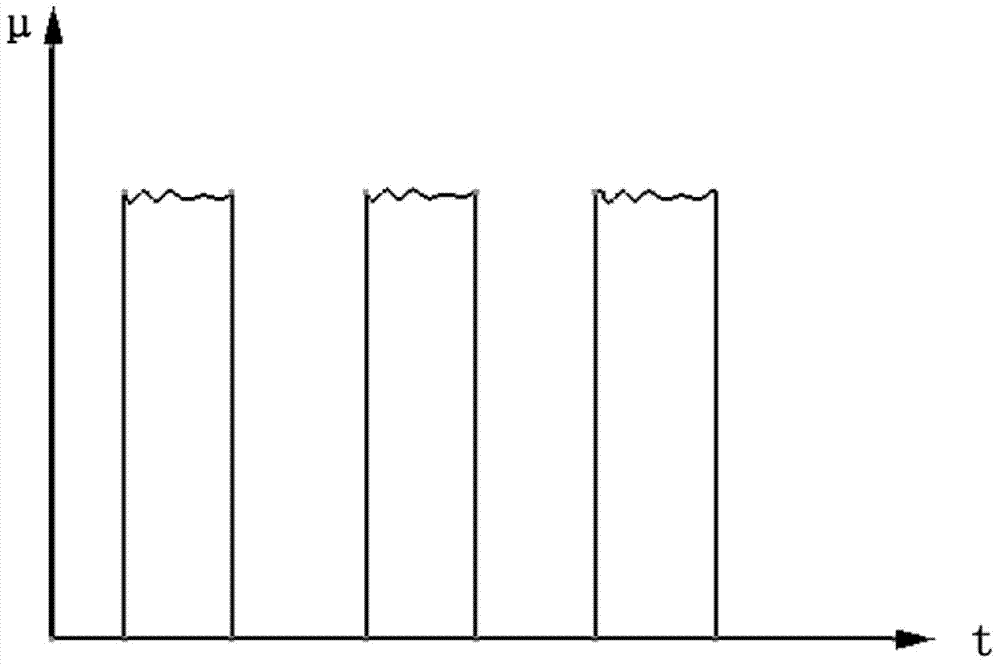

[0028] Specifically, the present invention relates to a method for testing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com