Glow spectrometer alloy sample and preparation method thereof

A glow spectrometer and alloy technology, which is applied in the preparation of test samples, electrical excitation analysis, material excitation analysis, etc. Vacuum requirements, good testing foundation, simple sample preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: The alloy sample of the glow spectrometer is prepared by the following specific sample preparation method.

[0016] (1) Use copper powder with a particle size of 300 mesh and a purity of 99.9999% as the binder;

[0017] (2) According to the ratio of binder: alloy = 8:1 (mass), mix the binder with the alloy powder; For more than 300 mesh;

[0018] (3) Use a mortar to fully mix the binder and the alloy, and the grinding time is 15 minutes;

[0019] (4) The alloy sample can be obtained by using a tablet press for tablet sample preparation, and the pressure selected for tablet pressing is 45 tons.

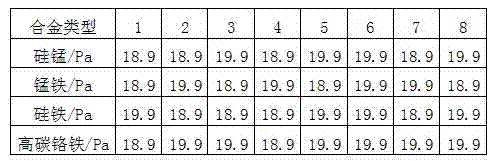

[0020] Table 1 is a list of vacuum degrees that can be achieved when the alloy samples obtained in this example are detected by a glow spectrometer.

[0021] Table 1: List of degrees of vacuum in Example 1

[0022]

Embodiment 2-5

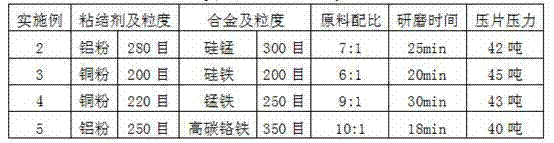

[0023] Embodiment 2-5: The alloy sample of the glow spectrometer is prepared by the following specific sample preparation method.

[0024] The raw materials and their particle sizes shown in Table 2, and the process conditions shown were used.

[0025] Table 2: Raw materials and processes of Embodiment 2-5

[0026]

[0027] In Table 2, the raw material ratio refers to the mass ratio of the binder to the alloy.

[0028] See Table 3 for a list of the vacuum degrees that can be achieved when the alloy samples obtained in Examples 2-5 are detected by a glow spectrometer.

[0029] Table 3: List of vacuum degrees (Pa) of Examples 2-5

[0030]

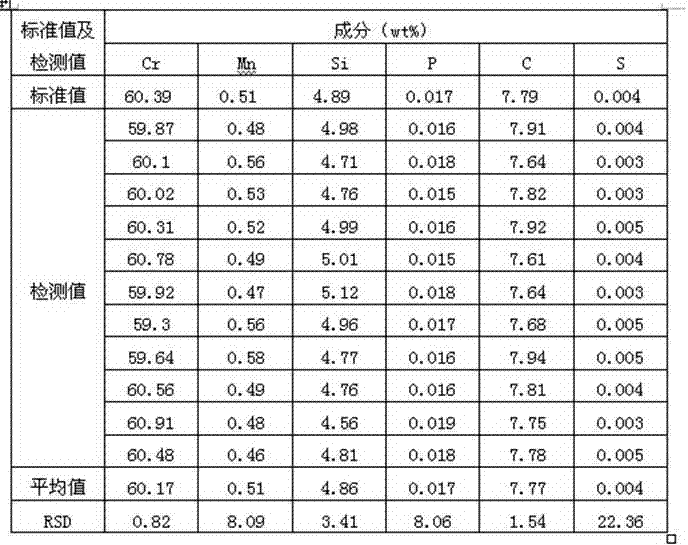

[0031] Repeatability test and accuracy test:

[0032] (1) Using the sample preparation method in Example 2, 11 sample preparations were carried out on the silicon-manganese alloy standard sample GSB (2011-2), and the repeatability test and accuracy test were respectively carried out with a glow spectrometer. The test data are shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com