Component Substrate And Alignment Method

A technology of component substrates and substrates, which is applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of inconsistent anchoring force and poor alignment, and achieve the effect of improving poor alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

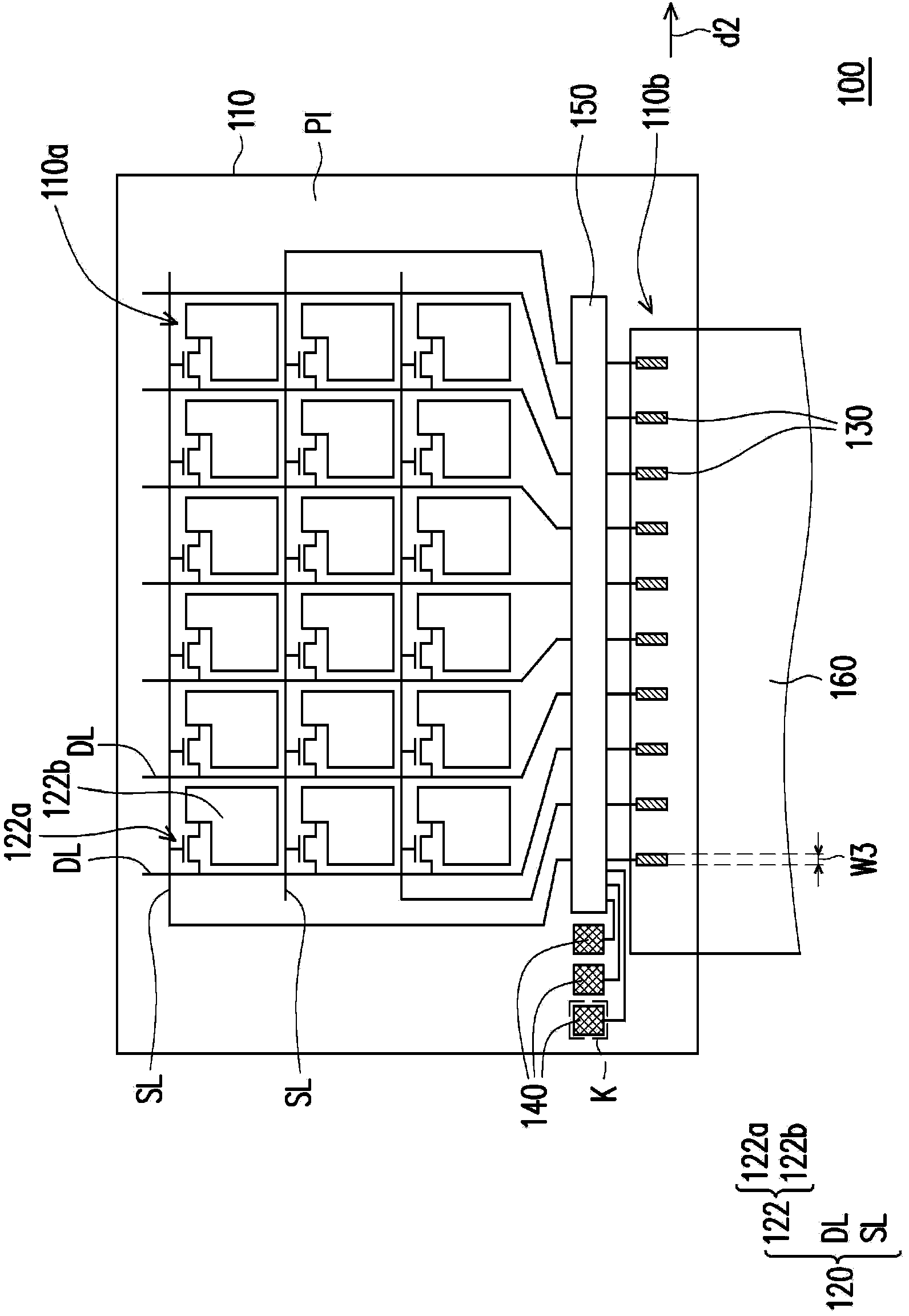

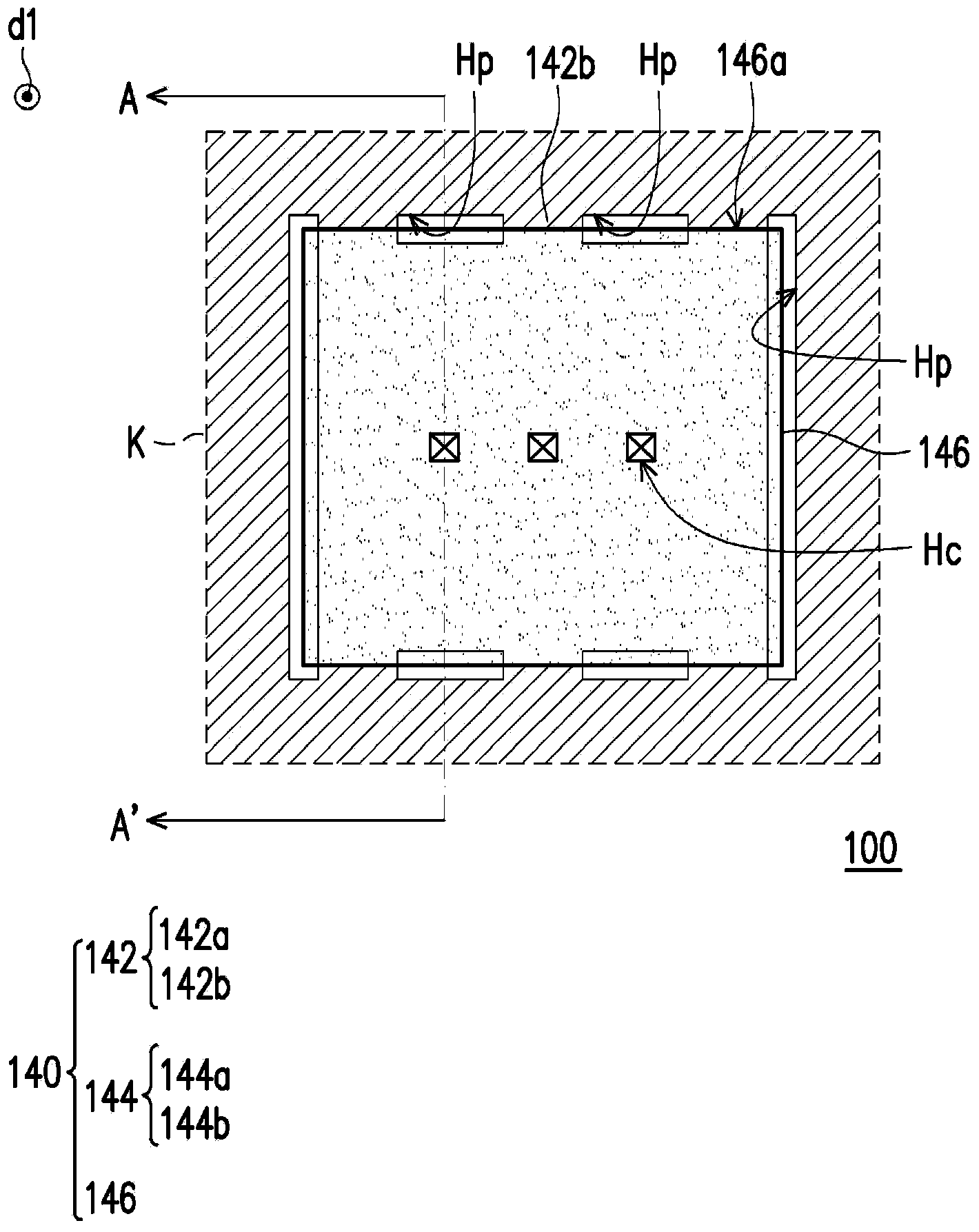

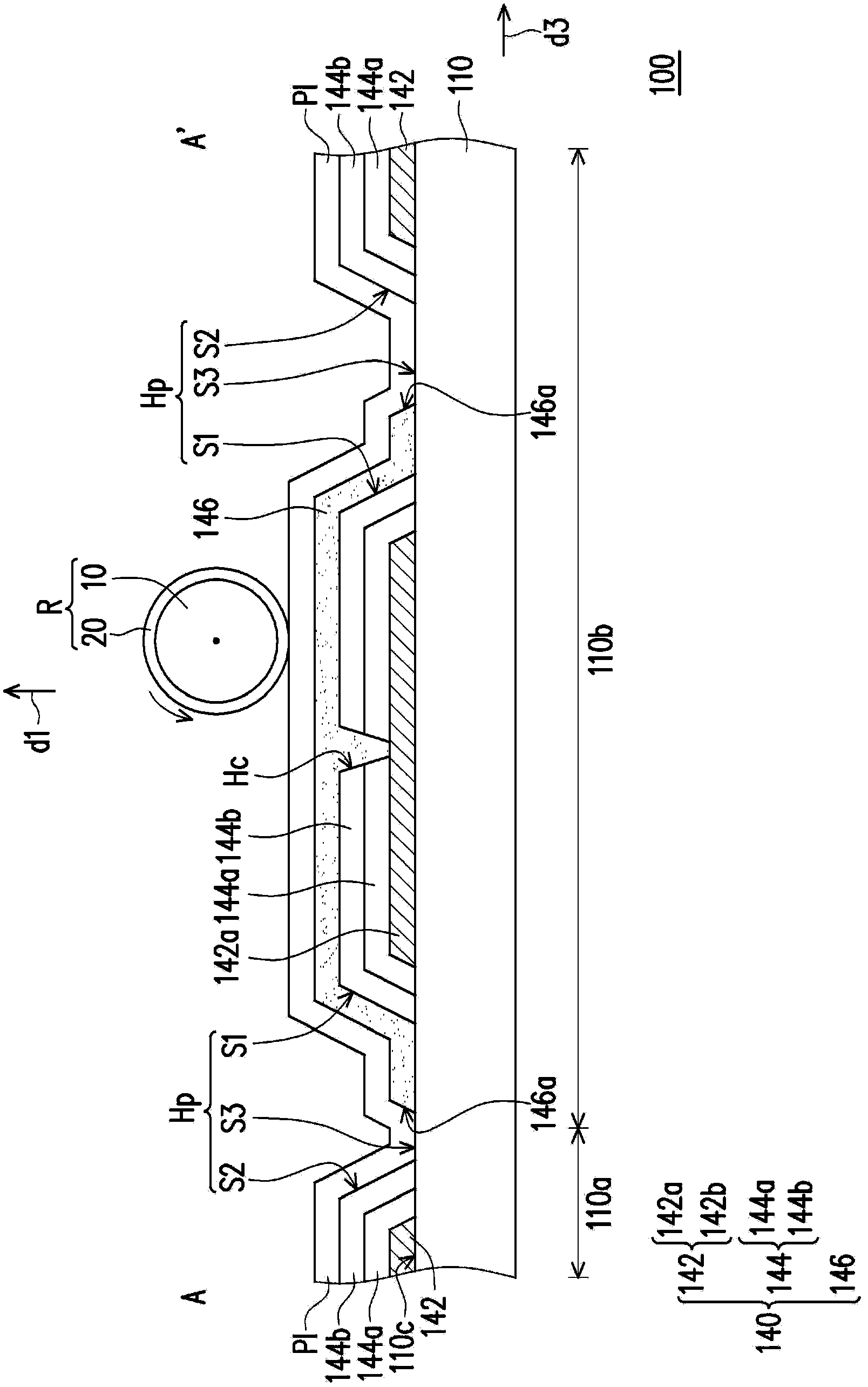

[0063] figure 1 It is a schematic top view of an element substrate according to an embodiment of the present invention. The device substrate 100 includes a substrate 110 , a pixel array 120 , a plurality of signal pads 130 and at least one test pad 140 . The substrate 110 has an active region 110a and a peripheral region 110b, the peripheral region 110b is connected to the active region 110a and surrounds the active region 110a. The pixel array 120 is located in the active region 110 a of the substrate 110 . A plurality of signal pads 130 are located in the peripheral region 110 b of the substrate 110 and are electrically connected to the pixel array 120 . At least one test pad 140 is located in the peripheral region 110 b of the substrate 110 and is electrically connected to the pixel array 120 . In this embodiment, the material of the substrate 110 can be glass, quartz, organic polymer, or opaque / reflective material (such as: conductive material, metal, wafer, ceramic, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com