High-fluid low-temperature early-strength cement-based grouting material

A technology of early-strength cement and grouting material, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as inability to guarantee grouting, freezing of materials, and inability to serve, so as to save manpower and material costs, The effect of overcoming poor stability and reliable quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

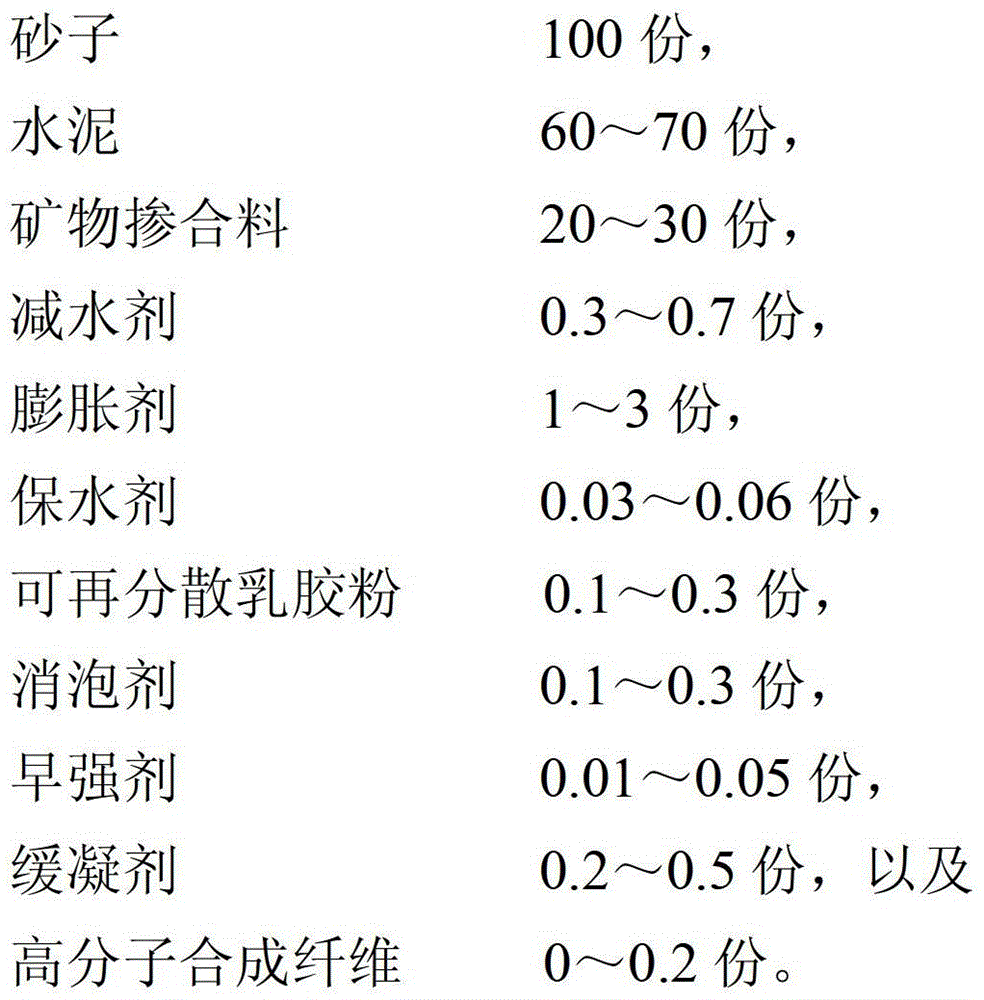

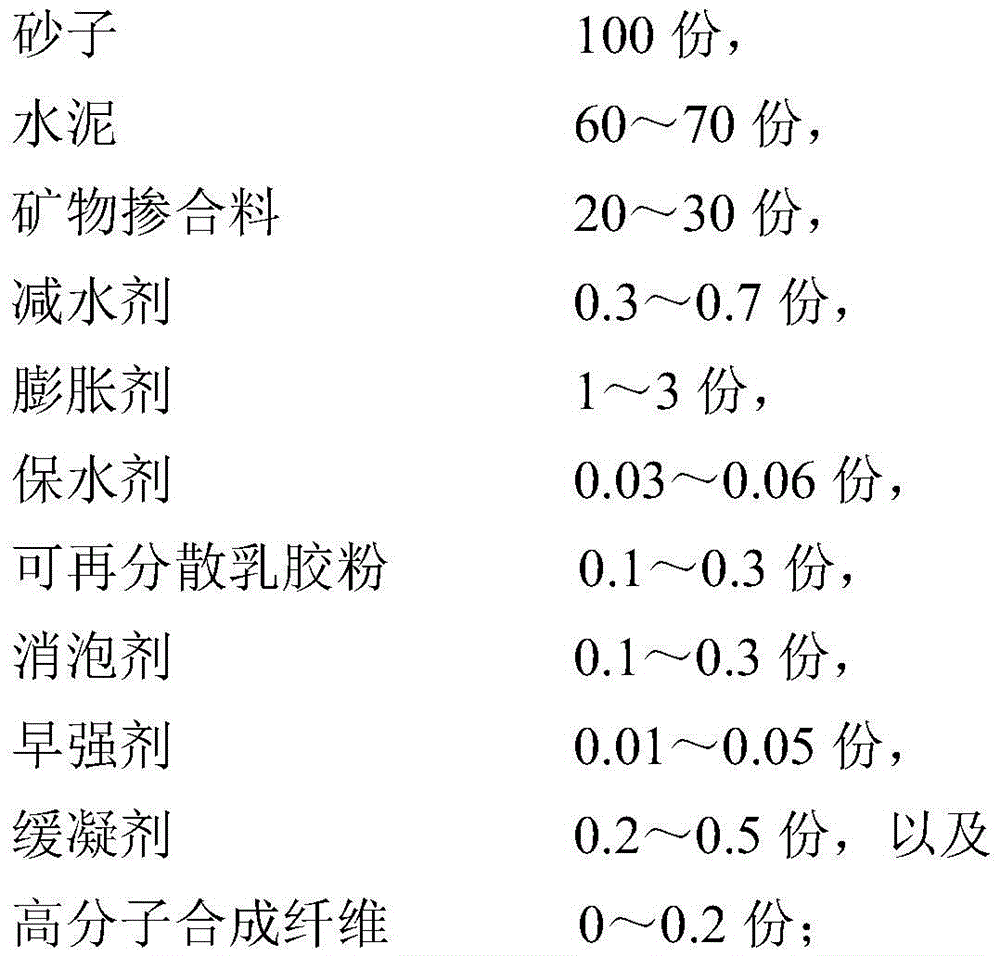

[0026] Take 100kg of quartz sand,

[0027] Rapid hardening sulfoaluminate cement 60kg,

[0028] Fly ash (mineral admixture) 30kg,

[0029] Polycarboxylate superplasticizer 0.5kg,

[0030] Hydroxypropyl methylcellulose ether (water retaining agent) 0.03kg,

[0031] Calcium oxide expansion agent 2kg,

[0032] Ethylene-vinyl acetate copolymer latex powder 0.1kg,

[0033] Silicone defoamer 0.1kg,

[0034] Lithium hydroxide (early strength agent) 0.02kg,

[0035] Sodium gluconate (retarder) 0.3kg,

[0036] 3mm polypropylene fiber 0.1kg.

[0037] Mix all components uniformly in a mixer to make grout 1.

[0038] Mix the grouting material 1 with 23kg of water evenly before applying it, and perform conventional maintenance at 5°C. The properties are as follows: initial fluidity 350mm; 1h fluidity 310mm; 1d compressive strength 31.3MPa; 28d compressive strength 75.1MPa.

Embodiment 2

[0040] Take 100kg of quartz sand,

[0041] Rapid hardening sulfoaluminate cement 70kg,

[0042] Fly ash (mineral admixture) 20kg,

[0043] Polycarboxylate superplasticizer 0.5kg,

[0044] Hydroxypropyl methylcellulose ether (water retaining agent) 0.03kg,

[0045] Calcium oxide expansion agent 3kg,

[0046] Ethylene-vinyl acetate copolymer latex powder 0.2kg,

[0047] Silicone defoamer 0.1kg,

[0048] Lithium hydroxide (early strength agent) 0.02kg,

[0049] Sodium gluconate (retarder) 0.3kg,

[0050] 3mm polypropylene fiber 0.1kg.

[0051] Mix all components uniformly in a mixer to make grout 2.

[0052] Mix the grouting material 2 with 23kg of water evenly before applying it, and perform conventional maintenance at 5°C. The performance is as follows: initial fluidity 345mm; 1h fluidity 305mm; 1d compressive strength 35.6MPa, 28d compressive strength 79.1MPa.

Embodiment 3

[0054] Take 100kg of quartz sand,

[0055] Rapid hardening sulfoaluminate cement 65kg,

[0056] Fly ash (mineral admixture) 25kg,

[0057] Polycarboxylate superplasticizer 0.5kg,

[0058] Hydroxypropyl methylcellulose ether (water retaining agent) 0.03kg,

[0059] Calcium oxide expansion agent 3kg,

[0060] Ethylene-vinyl acetate copolymer latex powder 0.1kg,

[0061] Silicone defoamer 0.1kg,

[0062] Lithium hydroxide (early strength agent) 0.02kg,

[0063] Sodium gluconate (retarder) 0.3kg,

[0064] 3mm polypropylene fiber 0.1kg.

[0065] Mix the components uniformly in a mixer to make grout 3.

[0066] Mix the grouting material 3 with 23kg of water evenly before applying it, and perform conventional maintenance at 5°C. The properties are as follows: initial fluidity 345mm; 1h fluidity 310mm; 1d compressive strength 33.3MPa; 28d compressive strength 71.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com