High-heat-resistance non-cured asphalt waterproof coating and preparation method thereof

A kind of asphalt waterproof coating, high heat resistance technology, applied in the direction of asphalt coating, rosin coating, coating, etc., can solve the problems of waterproof layer aging, waterproof layer cracking, easy detachment of coatings and coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of following high heat-resistant non-cured asphalt waterproof coating mainly comprises as follows:

[0033] (1) Add asphalt and softened oil, and raise the temperature to 130°C to 190°C, stir to dissolve completely;

[0034] (2) Add rubber powder, control the temperature at 130°C-190°C, and stir evenly (for example, stir for 40-90 minutes).

[0035] (3) Add oxidized polyethylene wax to the system in step (2), control the temperature to 130°C-170°C, and stir evenly (for example, stir for 70-95 minutes).

[0036] (4) Add fillers in batches to the system in step (3), control the temperature at 130°C-170°C, and stir evenly (for example, stir for 120-150 minutes).

[0037] (5) Cool down to 130°C to 160°C, and then discharge and pack.

Embodiment 1

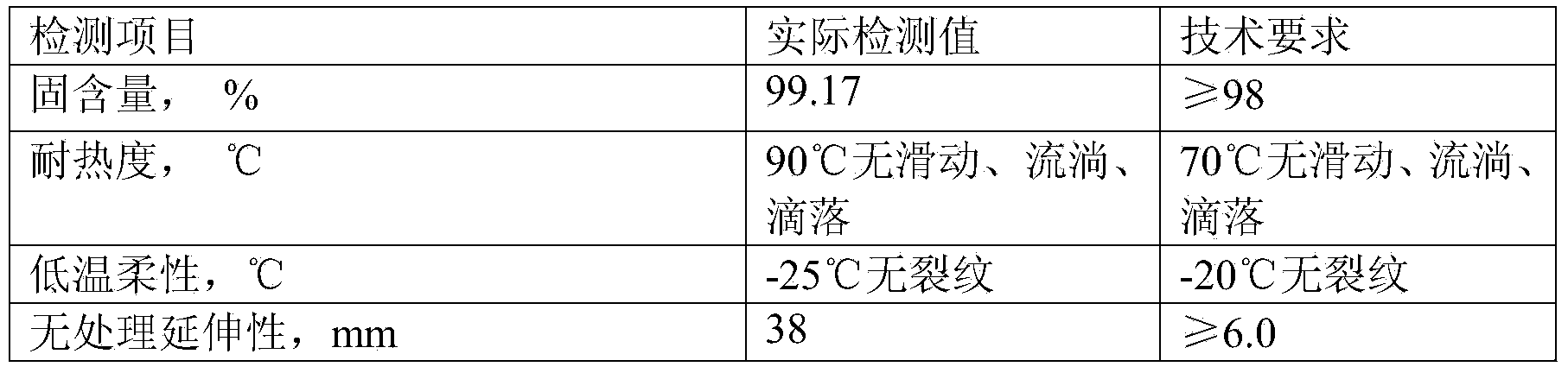

[0039] Add 170 parts of asphalt, 50 parts of softening oil, 18 parts of polysulfide rubber, 8 parts of rubber powder, 4 parts of oxidized polyethylene wax (copolymer of polyethylene), and 80 parts of filler (talcum powder) in order, start the colloid mill, Mix and stir at 130°C-190°C for 3-6 hours until the system is uniform, and the material is discharged to obtain a high heat-resistant non-curing asphalt waterproof coating. Its performance index detection is shown in the following table:

[0040] Table 1. Test results of non-cured asphalt waterproof coating with high heat resistance

[0041]

[0042]

Embodiment 2

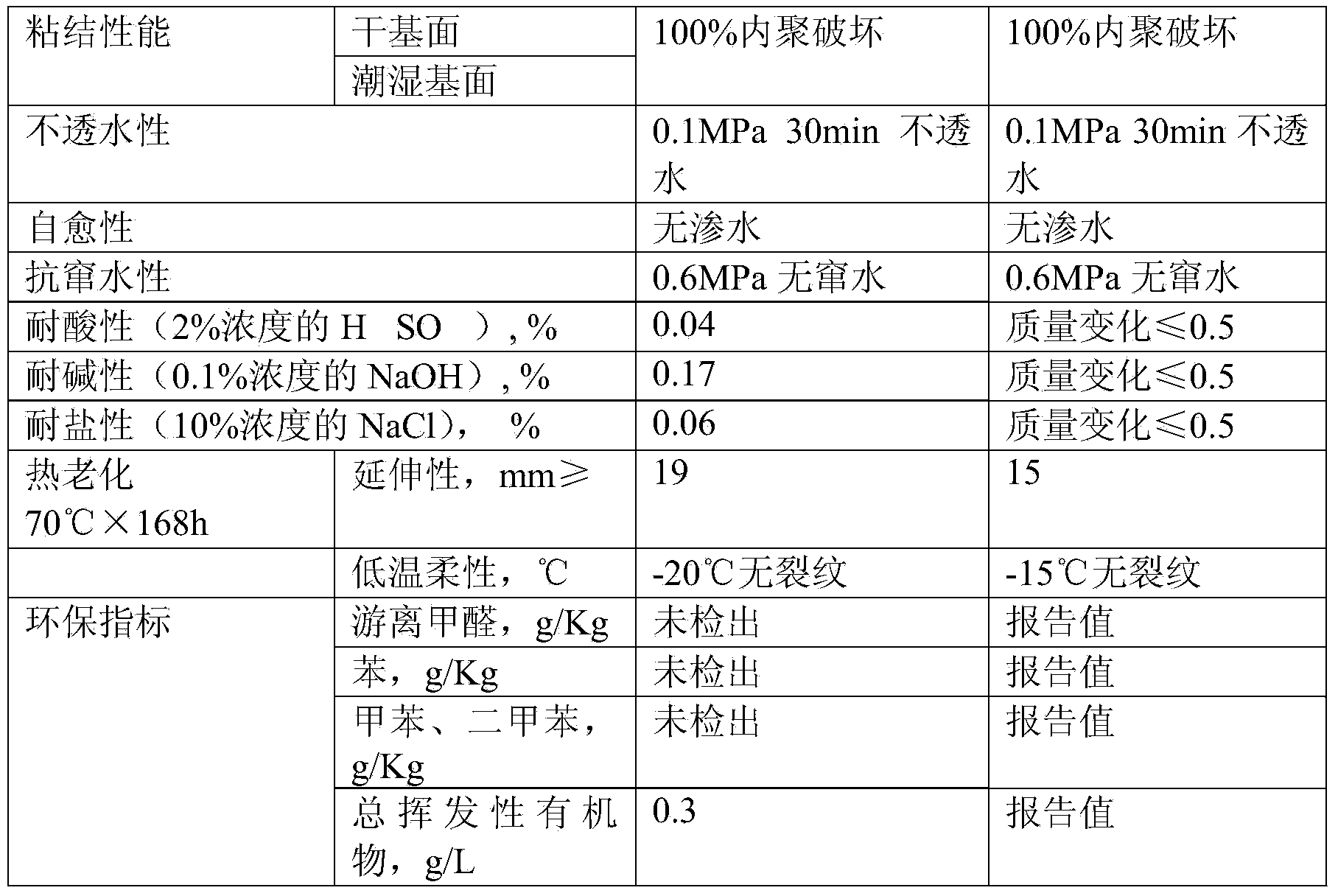

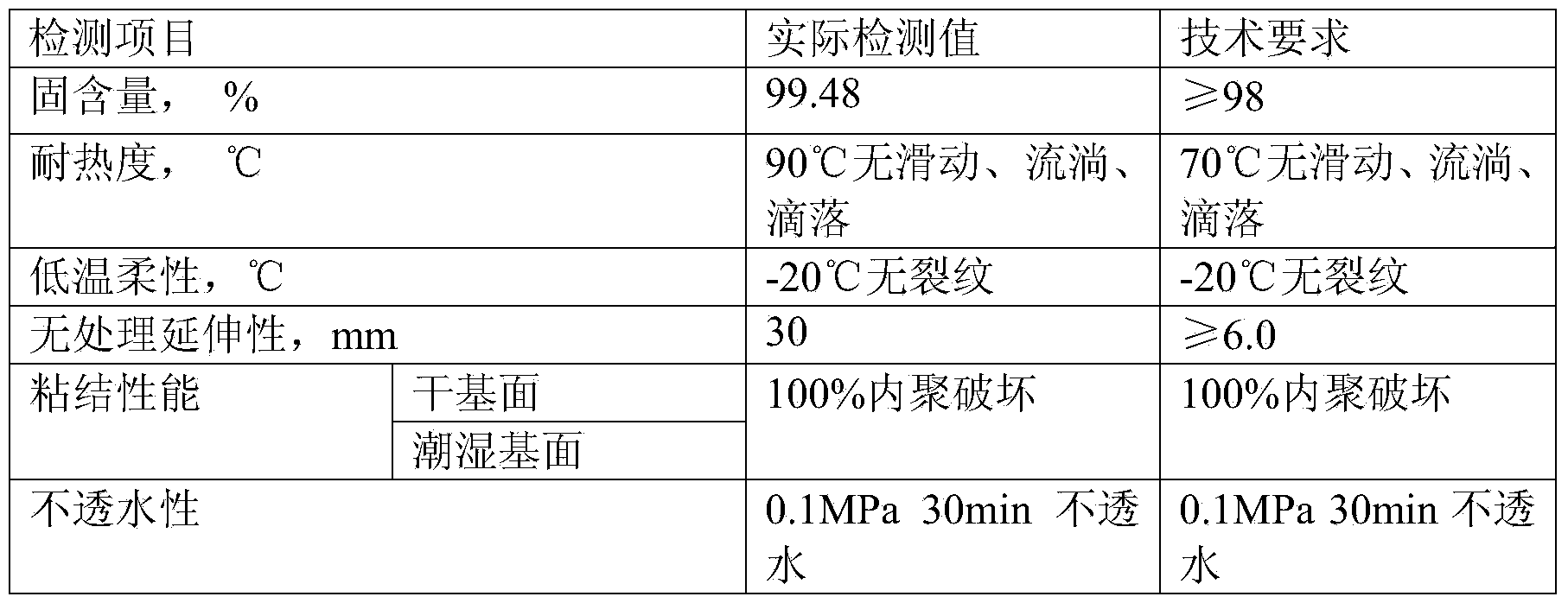

[0044] 220 parts of asphalt, 40 parts of softening oil, 15 parts of polysulfide rubber, 15 parts of rubber powder, 12 parts of oxidized polyethylene wax (graft polymer of polyethylene and vinyl acetate), 10 parts of rosin resin, 12 parts of plasticizer , 120 parts of filler (heavy calcium powder), 8 parts of defoamer are added in order, start the colloid mill, mix and stir at 130 ° C ~ 170 ° C for 4 ~ 8 hours, until the system is uniform, and the material is discharged, that is, high heat resistant Non-curing bituminous waterproof coating. Its performance index detection is shown in the following table:

[0045] Table 2. Performance index detection of non-cured asphalt waterproof coating with high heat resistance

[0046]

[0047]

[0048] The present invention is not limited to the above-mentioned examples, and within the scope of knowledge and literacy reserved by technical personnel in the field, it can also be extended according to the purpose of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com