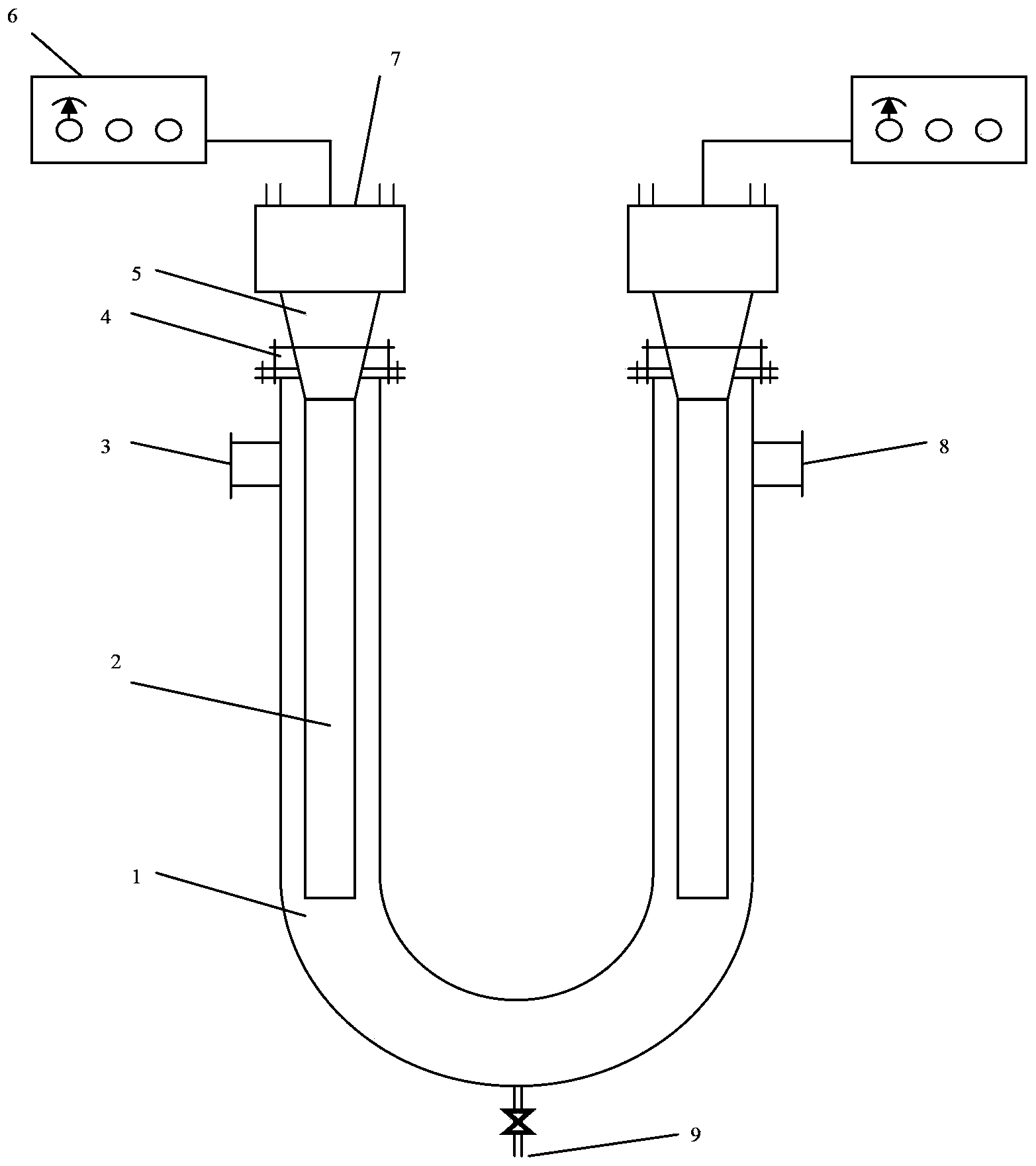

U-shaped pipe crude oil ultrasonic preprocessor and use method thereof

A preprocessor and U-shaped tube technology, applied in mechanical dehydration/demulsification, hydrocarbon oil treatment, petroleum industry, etc., to achieve the effect of large operating flexibility, simple process, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

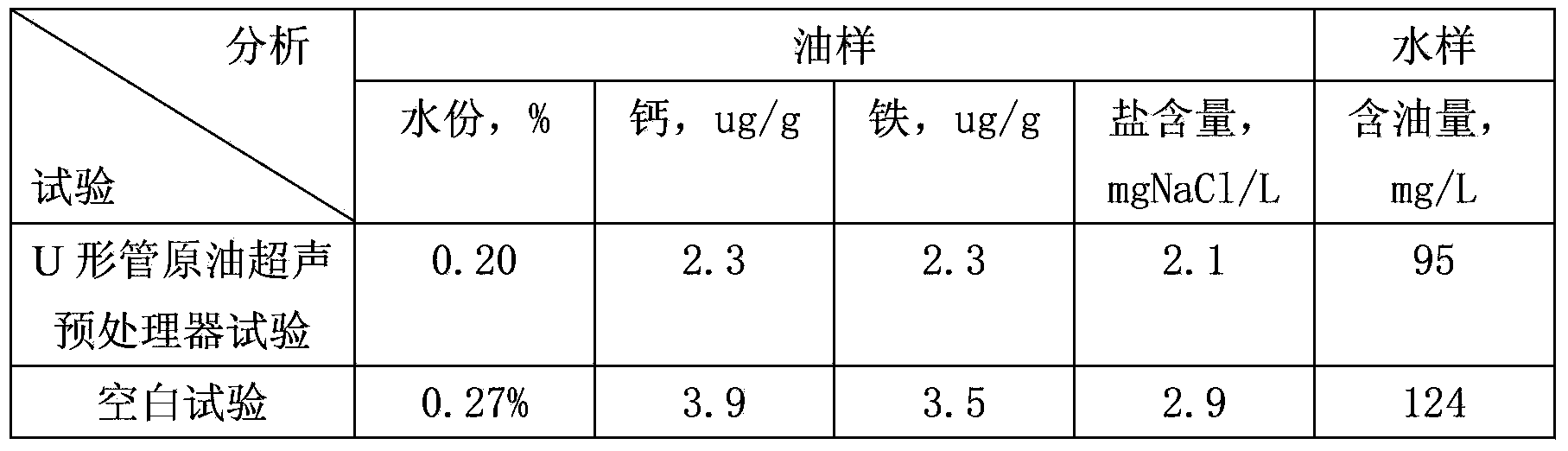

Embodiment 1

[0024] The U-shaped tube crude oil ultrasonic preprocessor used in this example was developed by China Petroleum Karamay Petrochemical Company. It is connected to a crude oil static mixer in front of it, followed by a crude oil electric desalting tank for 1 cubic test. The working frequency of the ultrasonic instrument is 21KHz, and the effective volume of the U-shaped tube after removing the ultrasonic horn is 22 liters. The oil used in the test is crude oil distilled and processed by the second set of Karamay Petrochemical Company, and its calcium and iron contents are 9.1ug / g and 5.0ug / g respectively. , The salt content is 17mgNaCl / L. According to 5% water injection, the amount of ammonium citrate added is twice the total molar number of calcium and iron. Continuous ultrasonic working mode, ultrasonic power 200W, demulsification ultrasonic device adopts pulse ultrasonic action mode, ultrasonic power 90W, ultrasonic action period 75ms, pulse width 9m, crude oil is taken from...

Embodiment 2

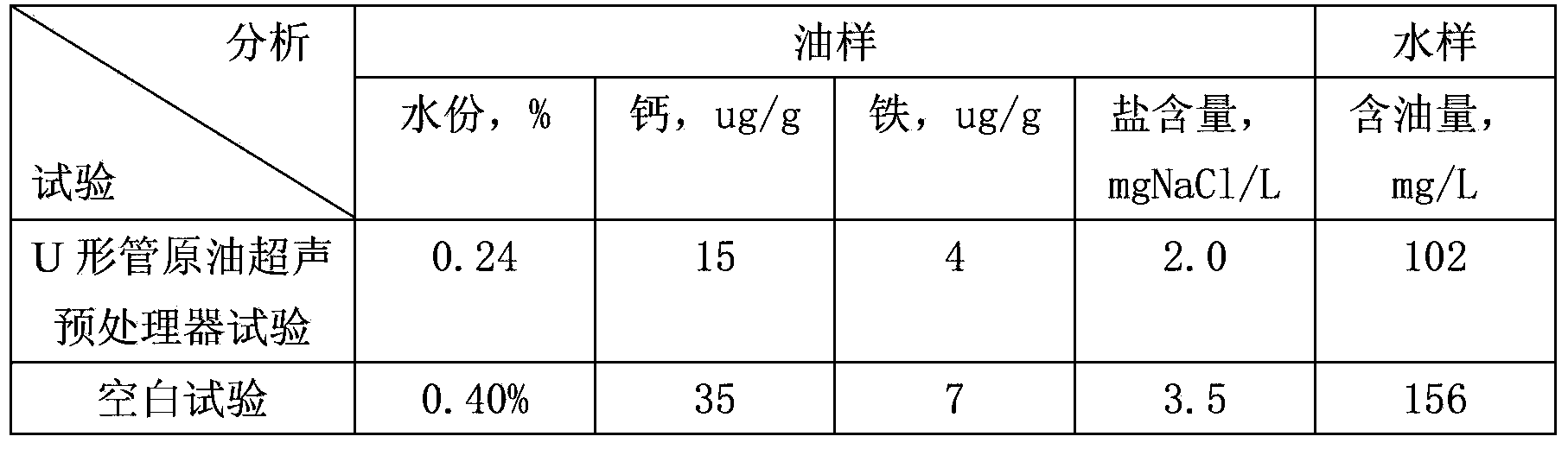

[0028] The U-shaped tube crude oil ultrasonic preprocessor used in this example was developed by China Petroleum Karamay Petrochemical Company. It is connected to a crude oil static mixer in front of it, followed by a crude oil electric desalting tank for 1 cubic test. The working frequency of the ultrasonic instrument is 35KHz, and the effective volume of the U-shaped tube after removing the ultrasonic horn is 40 liters. The oil used in the test is crude oil processed by the second coking unit of Karamay Petrochemical Company, and its calcium and iron contents are 240.6ug / g and 21.7ug / g respectively. g, the salt content is 3.9mgNaCl / L. According to 6% water injection, the amount of sulfamic acid added is 3 times of the total moles of calcium, iron and magnesium. The demulsifier adopts the continuous ultrasonic working mode, the ultrasonic power is 280W, the demulsification ultrasonic device adopts the pulse ultrasonic action mode, the ultrasonic power is 90W, the ultrasonic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com