Directly water-cooled rectangular planar target structure

A flat target and rectangular target technology, applied in the field of rectangular flat target and rectangular flat target structure, can solve the problem of affecting the effective utilization area of the target and the power of the target, the target and the magnetic assembly being fixed, and affecting the sputtering power supply of the target. Power and other issues, to achieve the effect of large-area uniform and rapid deposition of thin films, improving target utilization, and expanding uniform sputtering area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

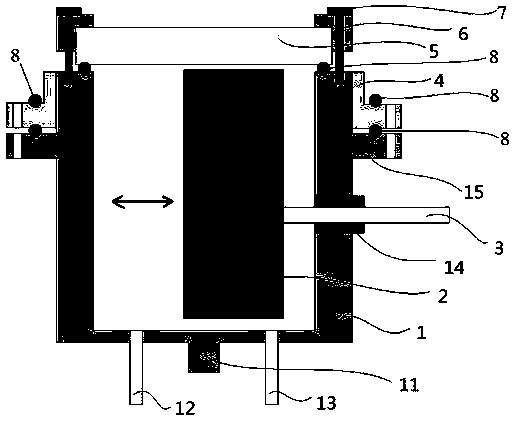

[0019] see figure 1 , a direct water-cooled rectangular planar target structure of the present invention generally includes three major components: a cooling pool 1 , a magnetic assembly 2 and a rectangular target 5 .

[0020] Wherein, the cooling pool 1 is used to accommodate cooling water, preferably made of metal copper or copper alloy, at the bottom end away from the open end is provided with: a cathode electrode 11, a cooling water inlet pipe 12 and a cooling water outlet pipe 13, generally That is, the cathode electrode 11 is arranged in the middle of the cooling water inlet pipe 12 and the cooling water outlet pipe 13, and can be fixed on the cooling pool 1 by means of screws or the like. Of course, the installation positions of the cooling water inlet pipe 12 and the cooling water outlet pipe 13 are not limited to this, as long a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com