Mini-tiller tensioning wheel mechanism

A tensioning wheel and tiller technology, applied in the field of tension devices, can solve the problem that it is difficult to accurately control the pushing amount of the belt by the tensioning wheel, the tension of the belt cannot reach the best state, and the precise control of the tensioning wheel cannot be achieved. and other problems, to achieve the effect of high tension, not easy to drift, and stable power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

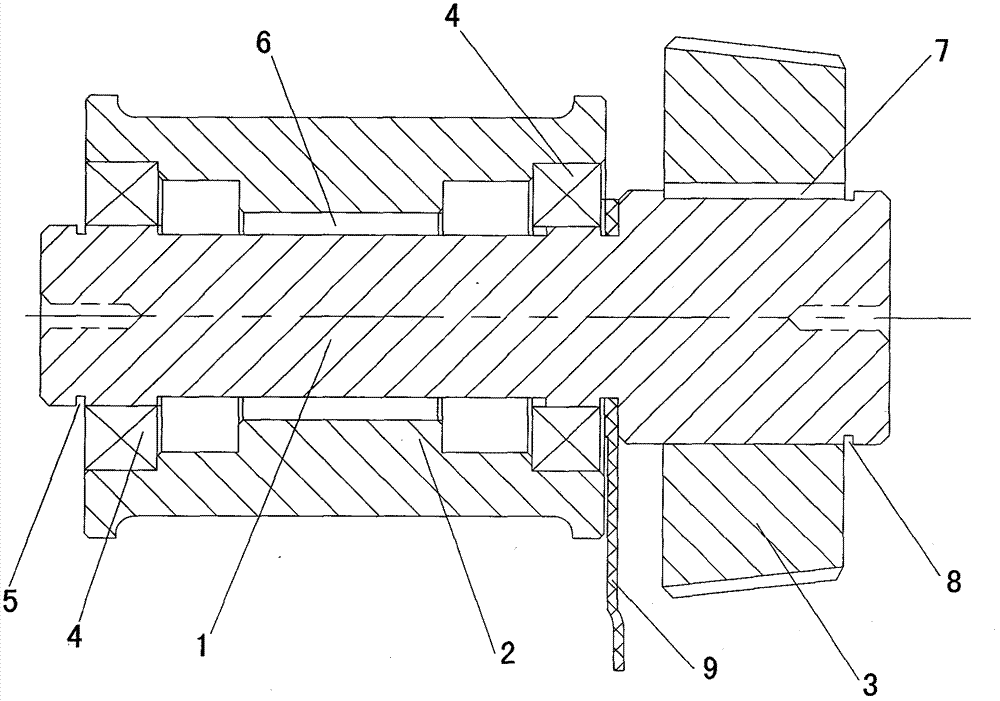

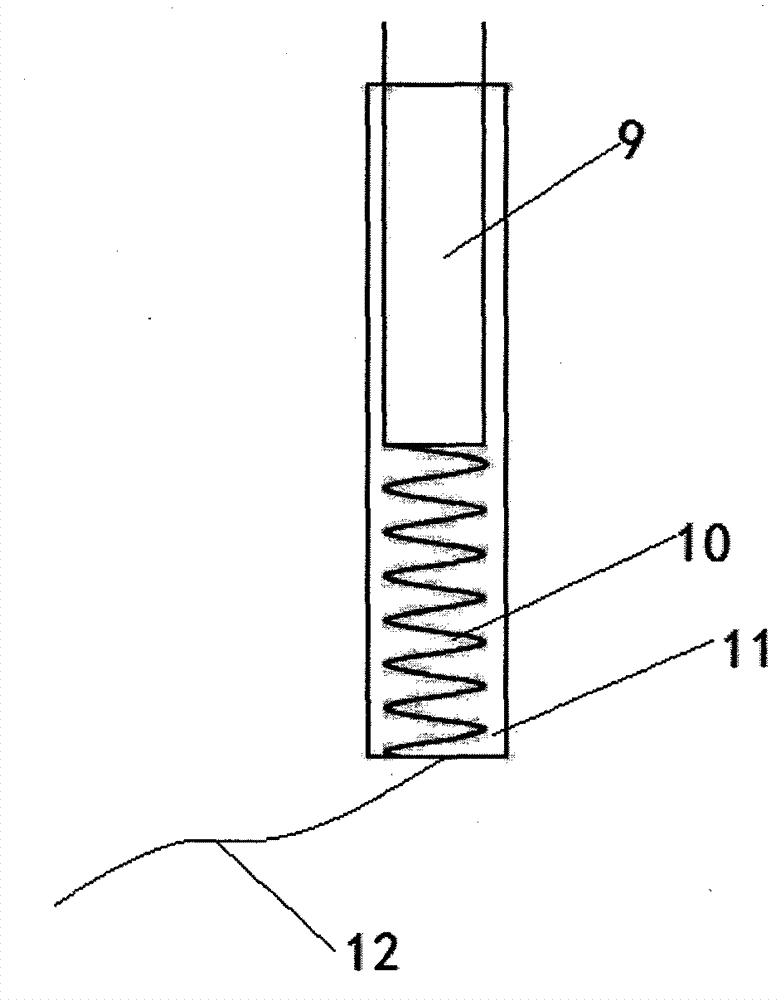

[0019] Such as figure 1 Shown is the structural representation of micro-tiller tension wheel mechanism of the present invention; figure 2 Shown is a structural schematic diagram of the supporter of the micro tiller tensioner mechanism of the present invention; a micro tiller tensioner mechanism of the present invention includes a support frame 9 and a tension wheel 2 that abuts on the transmission belt, and also includes a speed reduction shaft 1. The deceleration shaft is connected to the support frame 9, the tension wheel 2 is set on one end of the deceleration shaft 1 through the bearing 4, and the other end of the deceleration shaft 1 extends into the gearbox and is connected with Friction disc 3, said friction disc 3 is used for speed reduction near the transmission shaft.

[0020] In this embodiment, the micro tillage machine tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com