Electronic component automatic testing device

A technology for automatic testing devices and electronic components, which is applied in the directions of measuring devices, testing optical properties, optical testing flaws/defects, etc., and can solve problems such as high manual dependence, low testing efficiency, and low testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The device and method provided by the embodiments of the present invention will be described in detail below with reference to the figures.

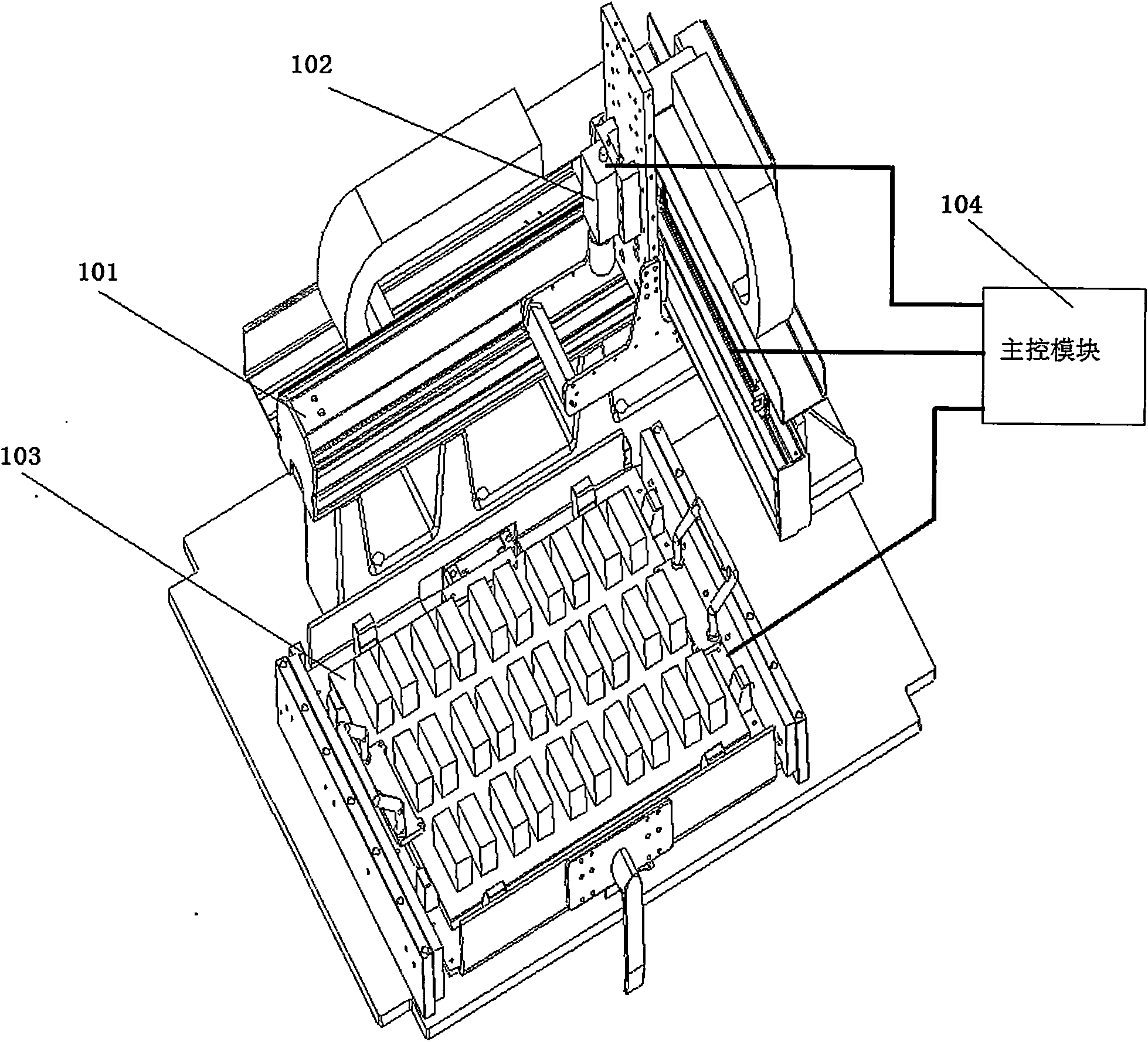

[0026] The system configuration of the embodiment of the present invention is as follows figure 1 shown, from figure 1 It can be seen that the automatic testing device for electronic components is mainly composed of the following parts: a robot arm motion platform 101 , an image acquisition module 102 , an electronic switching tooling board 103 , and a main control module 104 .

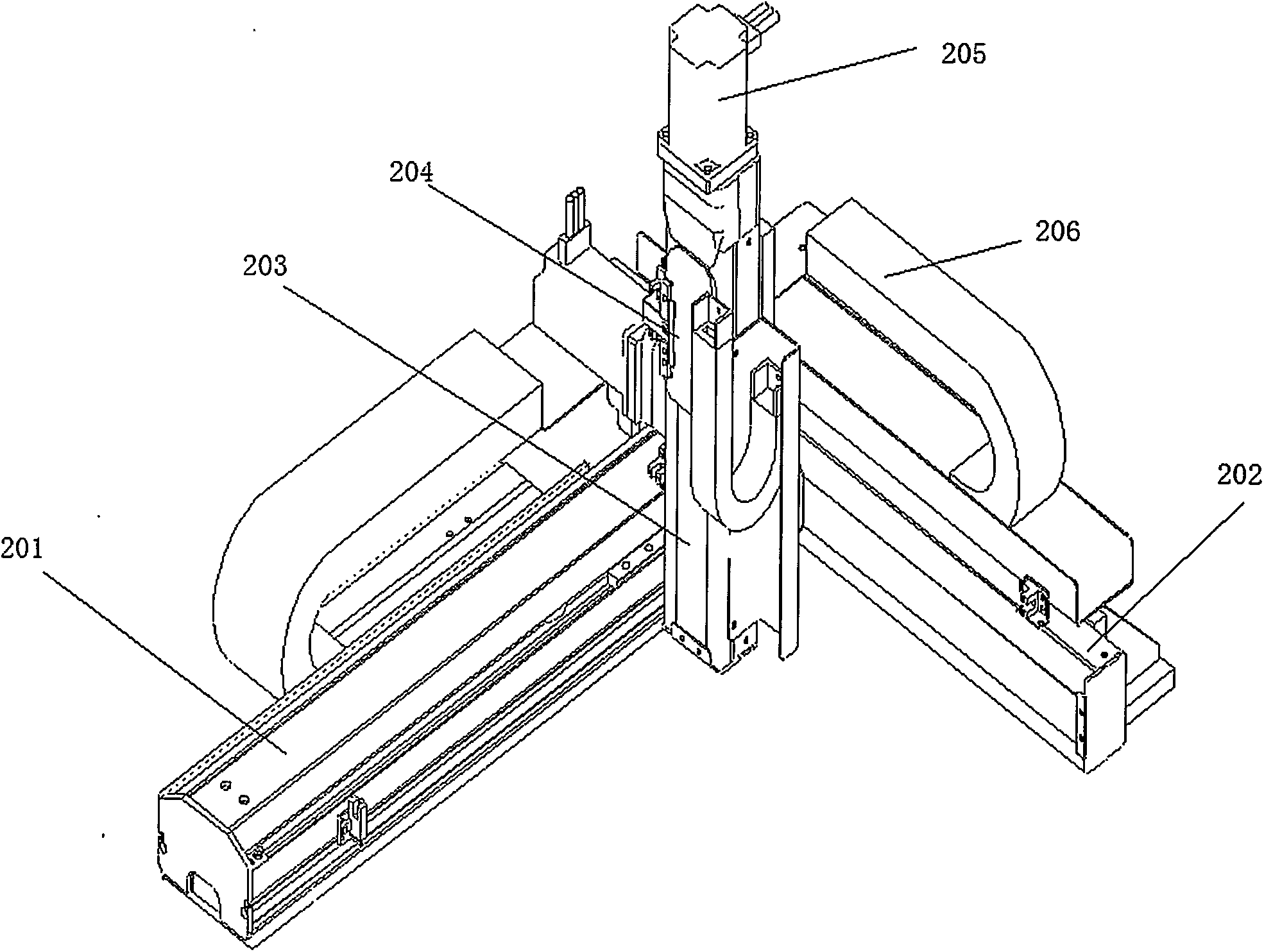

[0027] The mechanical arm motion platform 101, the mechanical arm motion platform is also called an industrial robot, figure 2 What is described is one of the embodiments, which is a three-dimensional Cartesian coordinate robot composed of three linear mechanical arms. Such an industrial robot can realize high-precision position movement in the covered three-dimensional space. Generally, the positioning accuracy can be Up to 0.02mm or more. Install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com