Full-electric bending machine control system

A technology of control system and bending machine, applied in general control system, control/adjustment system, comprehensive factory control, etc., can solve the problems of low position control accuracy, environmental pollution, uneven force on sliders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

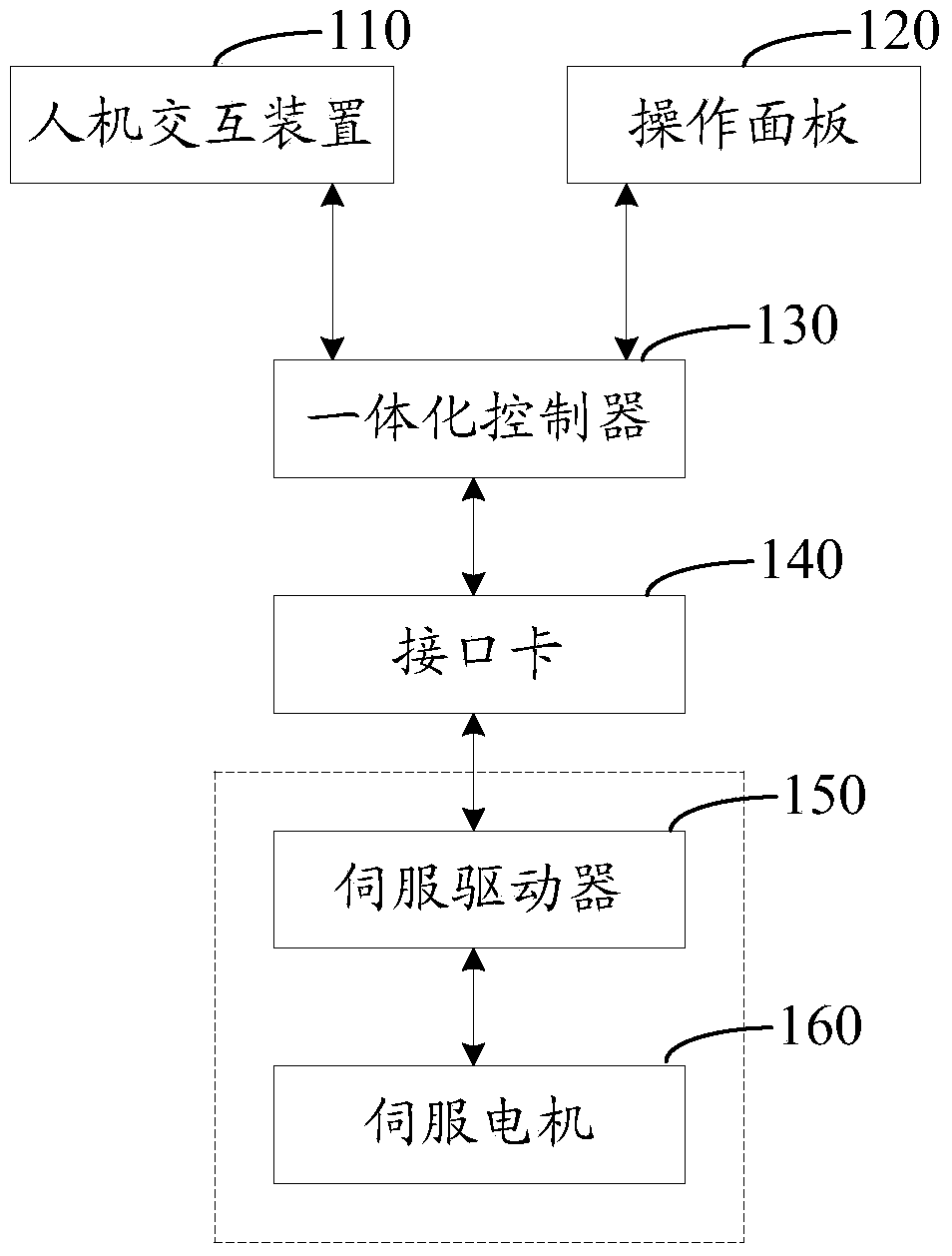

[0023] Please refer to figure 1 , is a schematic diagram of the structure of the all-electric bending machine control system in an embodiment.

[0024] The all-electric bending machine control system includes a human-computer interaction device 110 , an operation panel 120 , an integrated controller 130 and an interface card 140 .

[0025] The human-computer interaction device 110 is connected to the integrated controller 130 through a cross network cable, and is used for displaying status information of the all-electric bending machine. The state information includes the program being edited or running, the processing state, the graphic simulation of the bending process, the storage of the file, the calculation result of the processing data, and the like.

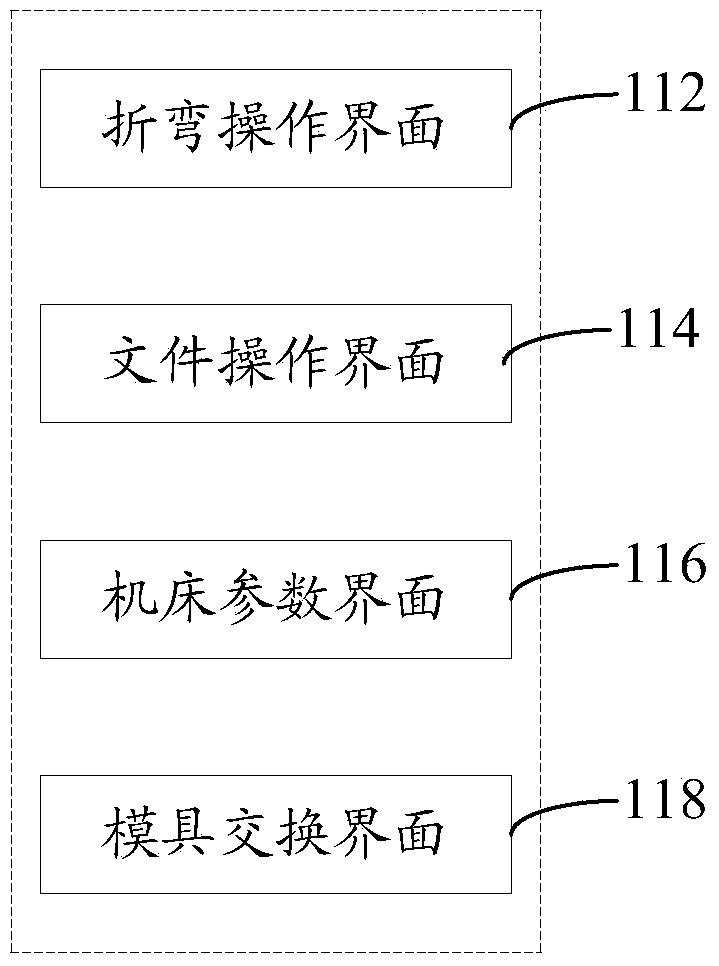

[0026] Please combine figure 2 . In this embodiment, the human-computer interaction device 110 is used to provide a bending operation interface 112 , a file operation interface 114 , a machine tool parameter interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com