Flexible fabric based serial multi-joint-angle detection system

A flexible fabric and detection system technology, applied in the fields of motion monitoring and medical monitoring, signal detection, sensing technology and transmission, and intelligent robots, can solve the problems of reducing reliability, occupancy of capacitive detection chips, and unable to meet motion detection without motion obstacles. requirements and other issues to achieve the effect of reducing the sense of obstacles and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

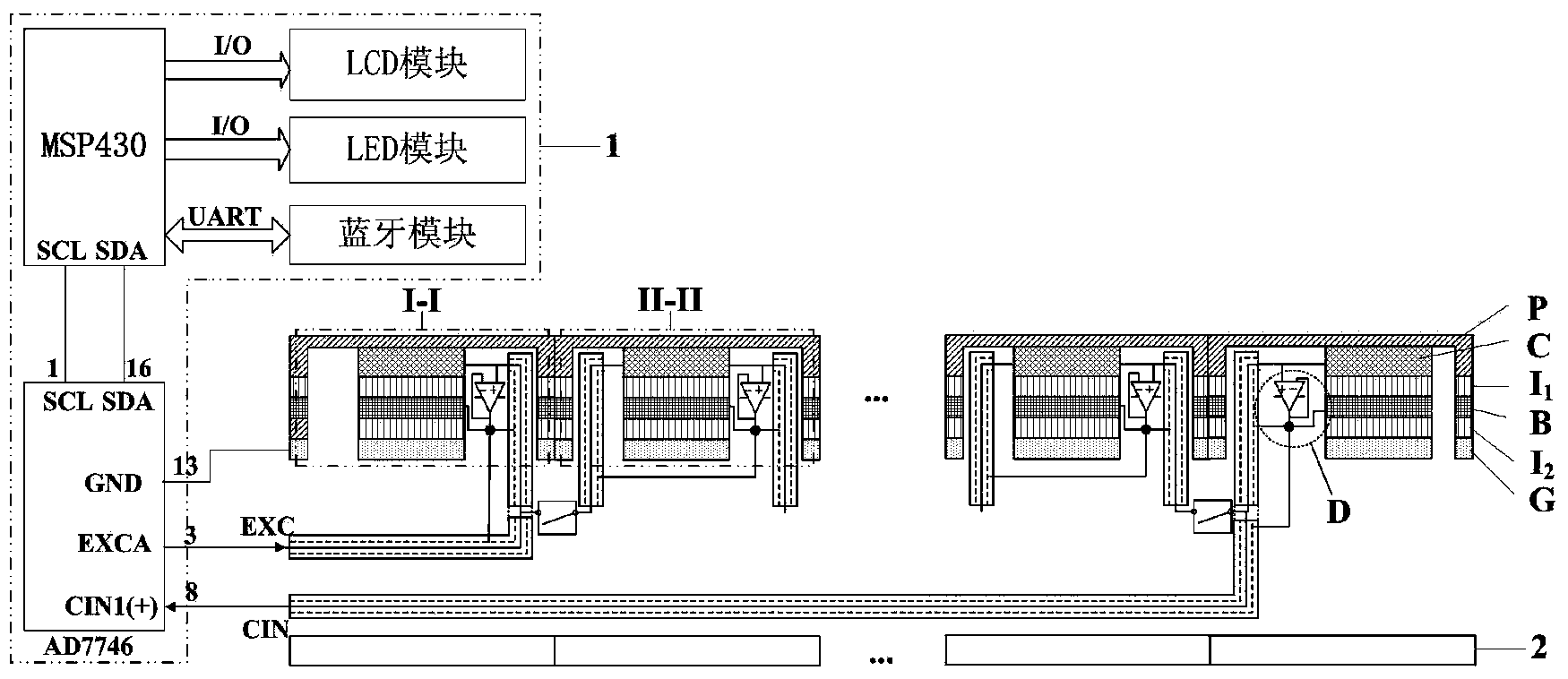

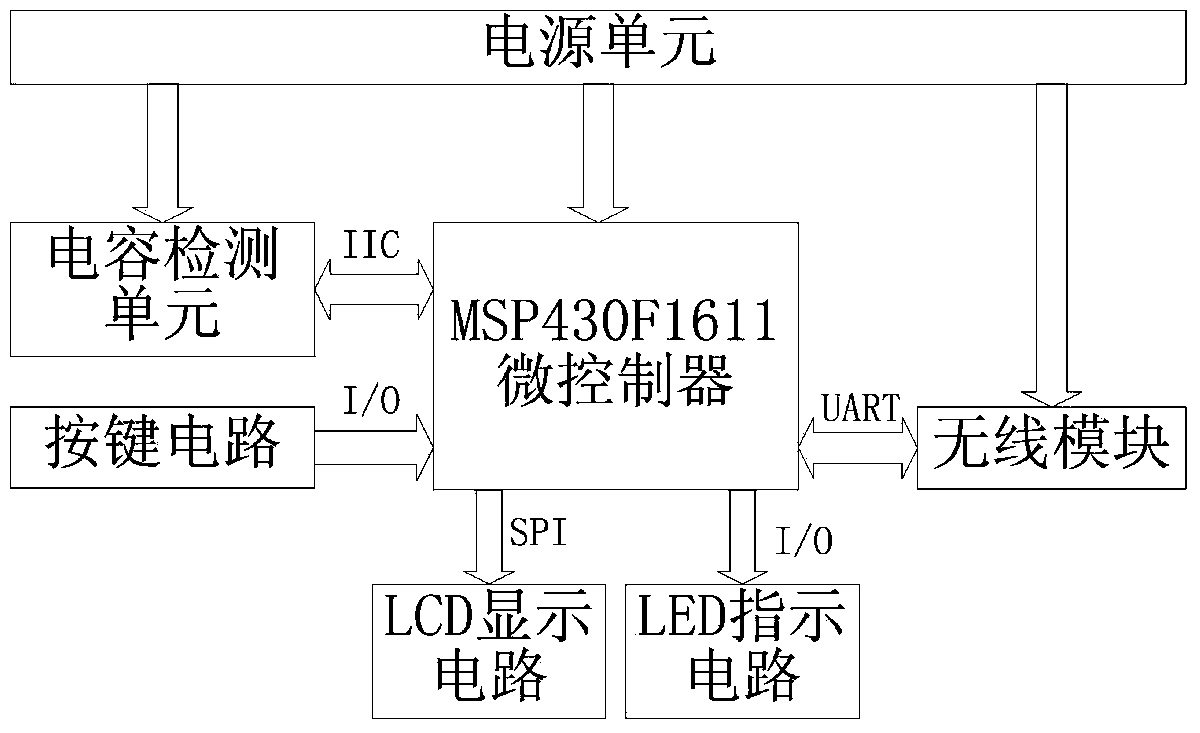

[0035] A multi-joint angle integrated serial detection system based on flexible fabric, as shown in Figure 1, includes: an elastic electrical insulation base layer 2, a micro switch corresponding to each joint one-to-one, and a micro switch located on both sides of each joint. The first sensing pole plate I-I and the second sensing pole plate II-II are equipped with flexible polyimide insulation on the first sensing pole plate I-I and the second sensing pole plate II-II The protective layer P, the first sensing pole plate I-I and the second sensing pole plate II-II adopt a sensing unit structure, and the sensing unit structure includes polypyrrole conductive fabric capacitor plates C facing each other And the polypyrrole conductive fabric formation G, between the polypyrrole conductive fabric capacitor plate C and the polypyrrole conductive fabric formation G, a conductive silicone rubber shielding layer B is provided, between the polypyrrole conductive fabric capacitor plate C...

Embodiment 2

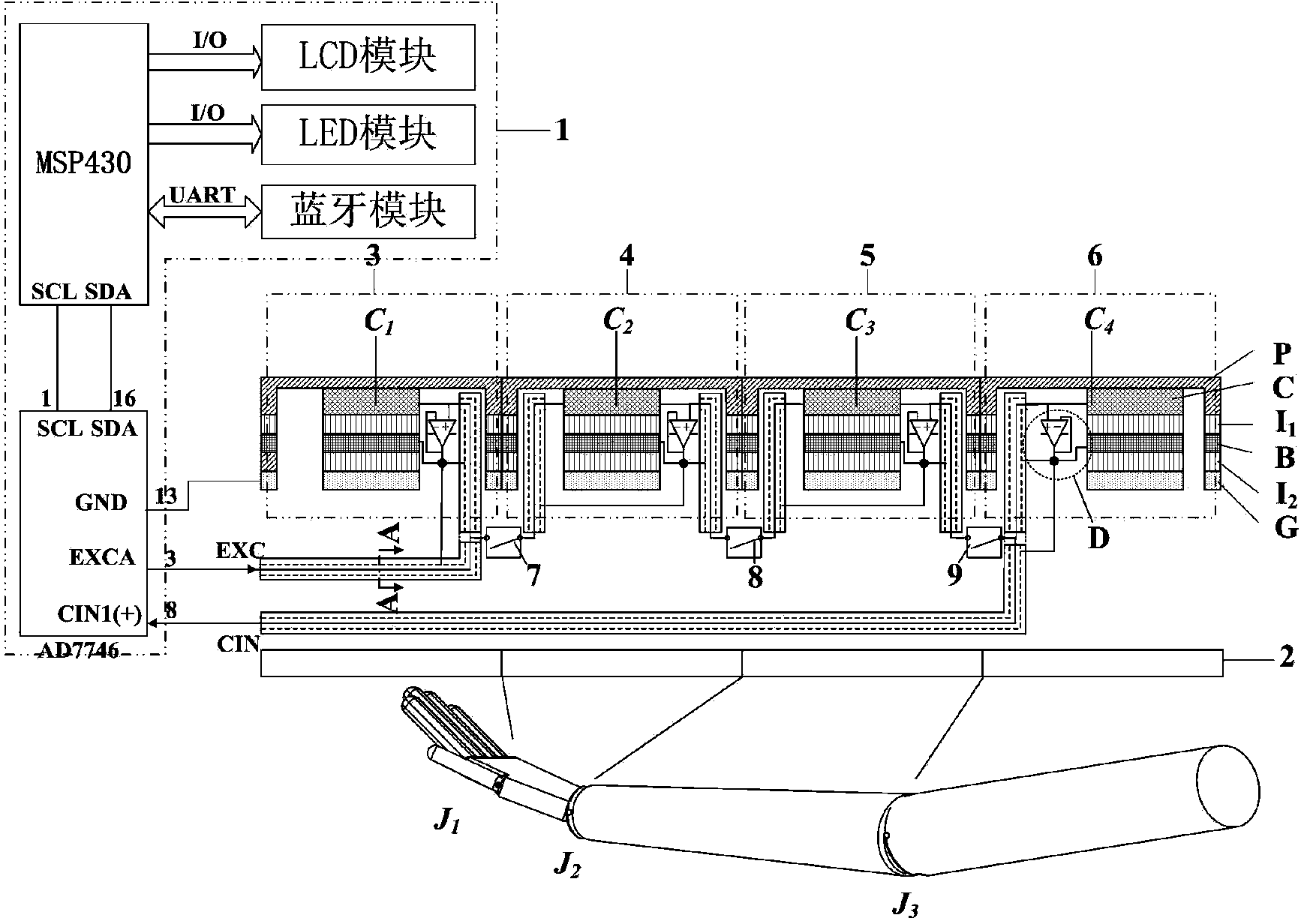

[0037] A three-joint angle detection sensor system based on flexible fabric, as shown in Figure 2, includes: an elastic and electrically insulating base layer 2, first micro-joints corresponding to the first joint, the second joint, and the third joint, respectively. Dynamic switch 7, the second micro switch 8, the third micro switch 9 and the front sensing pole plate 3, the secondary front sensing pole plate 4, the secondary rear sensing pole plate 5, the rear sensing pole plate 6, The front sensing pole plate 3 is located at the front end of the first joint, the secondary front sensing pole plate 4 is located between the first joint and the second joint, and the secondary rear sensing pole plate 5 is located between the second joint and the third joint, The rear sensing pole plate 6 is located at the rear end of the third joint, and the front sensing pole plate 3, the secondary front sensing pole plate 4, the secondary rear sensing pole plate 5 and the rear sensing pole plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com