Regenerator for reducing dead zone catalyst

A catalyst and regenerator technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalyst, chemical instruments and methods, etc., can solve the problems of high cost, waste, increase processing cost, etc., to reduce processing cost and save Catalyst, effect of short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

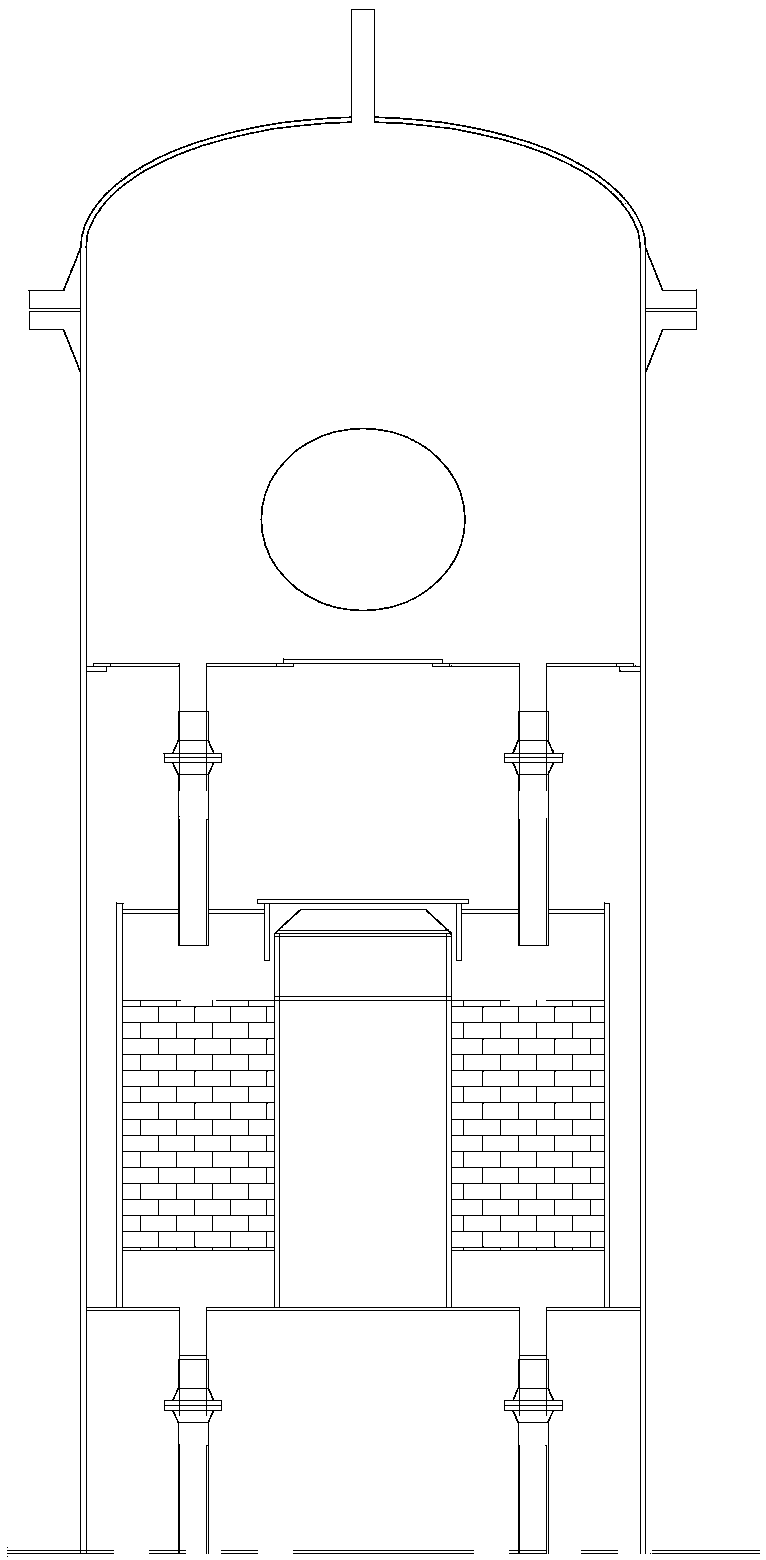

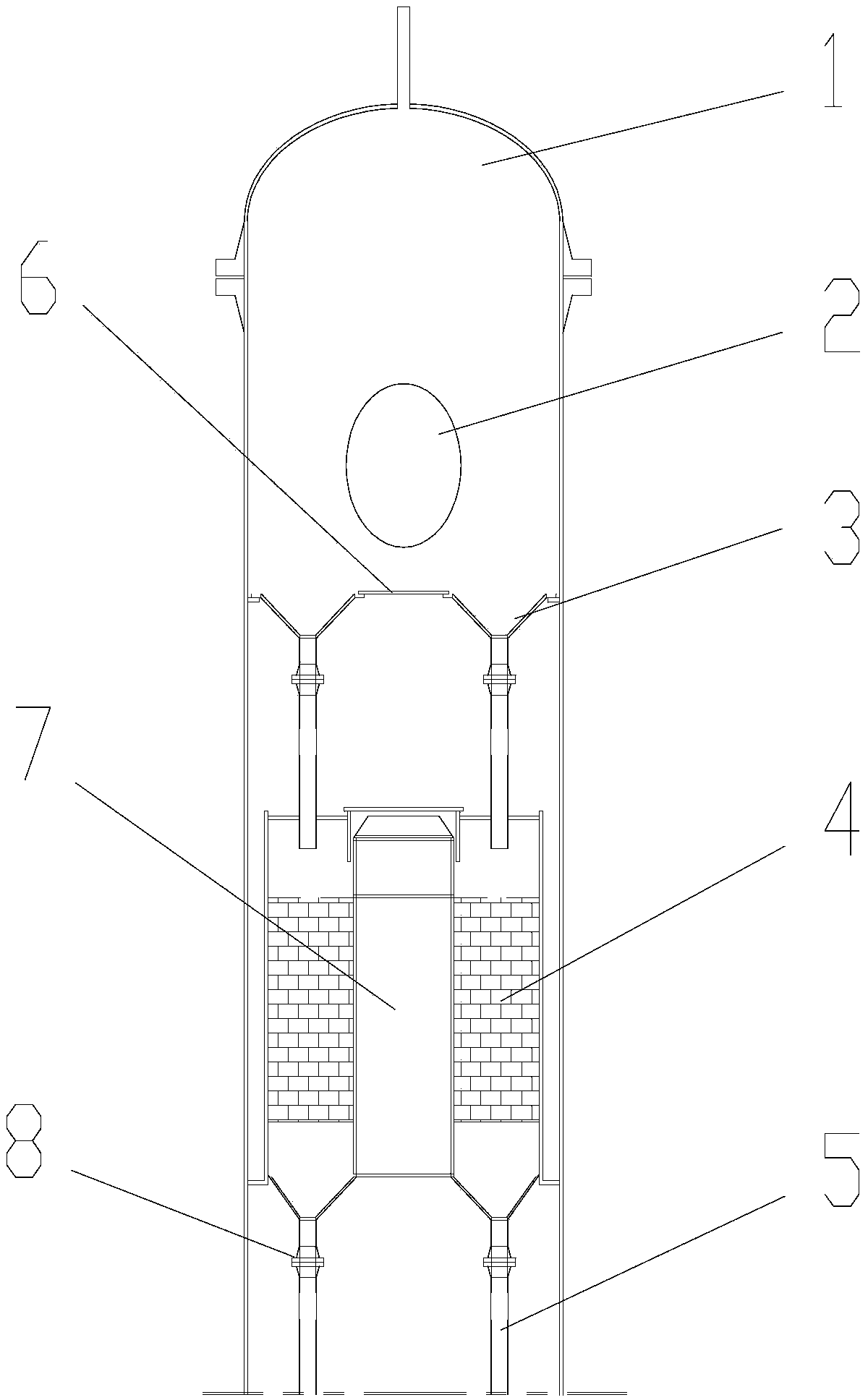

[0017] use figure 2 The structure of the catalyst regenerator shown.

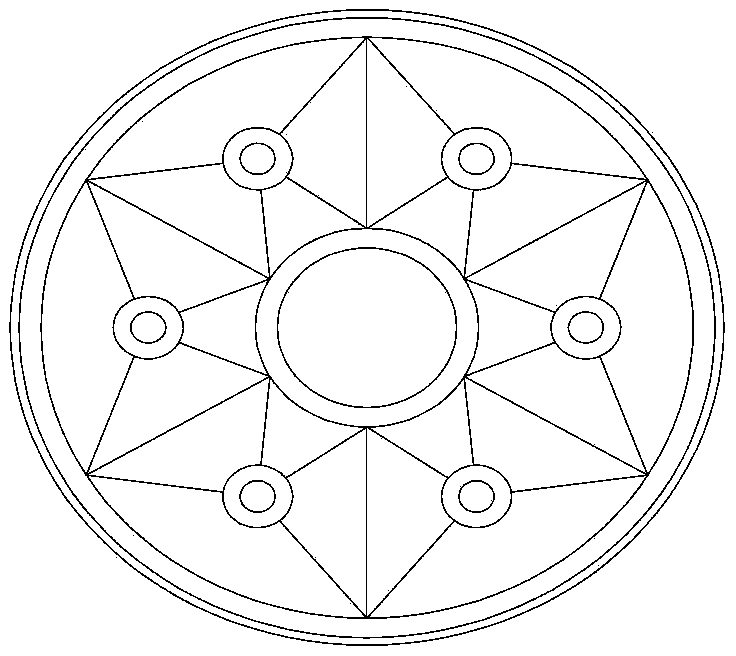

[0018] The support bed for the catalyst buffer zone and the support bed for the first-stage coking zone are respectively composed of 6 conical funnels, and the lower part is the catalyst delivery nozzle. The outside of the tapered funnel is fixed on the support ring with bolts along the circumferential direction. The catalyst enters the buffer zone from the feed port, and enters the first-stage charring zone from the conveying pipe through the conical funnel by its own gravity, and then enters the second-stage charred zone from the conveying pipe through the conical funnel by its own gravity. The tapered funnel part is welded from four plates.

[0019] The use of the catalyst regenerator of the present invention prevents the catalyst from remaining in the buffer zone and the burnt area, ensures the smooth feeding of the catalyst, and reduces the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com