A kind of rail grinding grinding wheel and its preparation method

A technology for grinding wheels and rails, applied in the field of grinding wheels, can solve the problems of unreasonable ratio of resin powder, single abrasive, and inappropriate selection of filler components, etc., to achieve good self-sharpening, high hardness, high efficiency and good surface finish Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

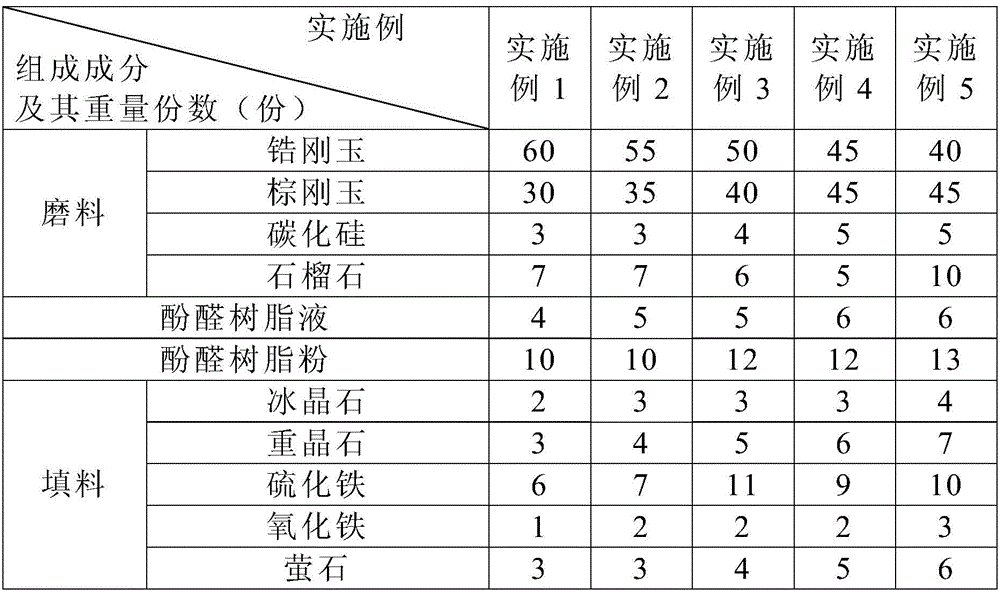

[0042] First, take the raw material by the composition and parts by weight of the rail grinding wheel of Example 1 in Table 1, the particle size of the abrasive in the raw material is controlled at 20#-60#, and the particle size of the phenolic resin powder is 200-320 mesh, The particle size of the filler is 200-320 mesh. Then add phenolic resin solution to the abrasive and stir for 8 minutes until the abrasive is fully soaked, and at the same time mix the filler and phenolic resin powder evenly to obtain a powder, and finally add the wetted abrasive to the mixed powder, and stir for 8 minutes to obtain a molding material.

[0043] Then, assemble the mold, put it into the iron die-casting matrix, weigh the appropriate weight of the molding material, put it into the molding mold and flatten it, at a temperature of 45°C and a pressure of 15N / mm 2 Under the condition of pressing for 15s, a grinding wheel blank is obtained. Then the pressed grinding wheel blank is dried in an ove...

Embodiment 2

[0046] First, weigh the raw materials according to the composition and parts by weight of the rail grinding wheel in Example 2 in Table 1. The particle sizes of the abrasives in the raw materials are respectively: zirconium corundum 20#-30#, brown corundum 30#-36#, carbonized Silicon 36#-46#, garnet 46#-60#, the particle size of phenolic resin powder is 200-260 mesh, the particle size of filler is respectively: cryolite 200-250 mesh, barite 250-280 mesh, vulcanization Iron 250-300 mesh, iron oxide 300-320 mesh, fluorite 250-320 mesh. Then add phenolic resin solution to the abrasive and stir for 8 minutes until the abrasive is fully soaked, and at the same time mix the filler and phenolic resin powder evenly to obtain a powder, and finally add the wetted abrasive to the mixed powder, and stir for 8 minutes to obtain a molding material.

[0047] Then, assemble the mold, put it into the iron die-casting matrix, weigh the appropriate weight of the molding material, put it into the...

Embodiment 3

[0050] First, weigh the raw materials according to the composition and parts by weight of the rail grinding wheel in Example 3 in Table 1. The particle sizes of the abrasives in the raw materials are respectively: zirconium corundum 20#-30#, brown corundum 30#-40#, carbonized Silicon 40#-50#, garnet 50#-60#, the particle size of phenolic resin powder is 250-300 mesh, the particle size of filler is: cryolite 250-300 mesh, barite 200-250 mesh, vulcanization Iron 250-300 mesh, iron oxide 250-300 mesh, fluorite 200-250 mesh. Then add phenolic resin solution to the abrasive and stir for 5 minutes until the abrasive is fully soaked, and at the same time mix the filler and phenolic resin powder evenly to obtain a powder, and finally add the wetted abrasive to the mixed powder, and stir for 5 minutes to obtain a molding material.

[0051] Then, assemble the mold, put the aluminum alloy material into the die-casting matrix, weigh the appropriate weight of the molding material, put it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com