Method for preparing ammonium dihydrogen phosphate and co-producing enhancement fertilizer special for onions

A technology of ammonium dihydrogen phosphate and enhanced fertilizer, applied in the direction of phosphate, phosphorus oxyacid, application, etc., can solve the problems of polluted environment, low absorption rate of onion, changing soil structure, etc., and achieve significant economic value and significant environmental protection value , the effect of less fertilizer input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

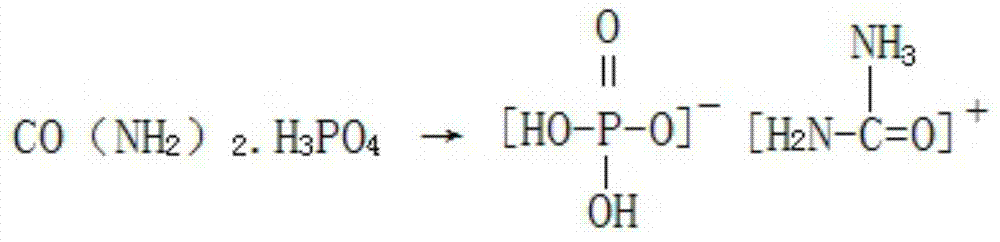

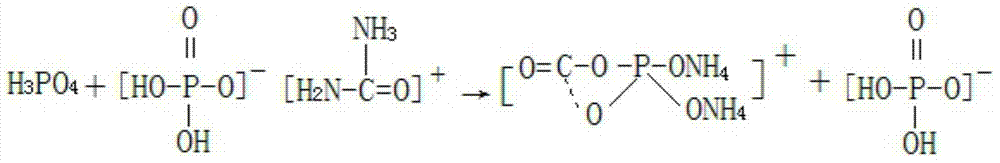

Method used

Image

Examples

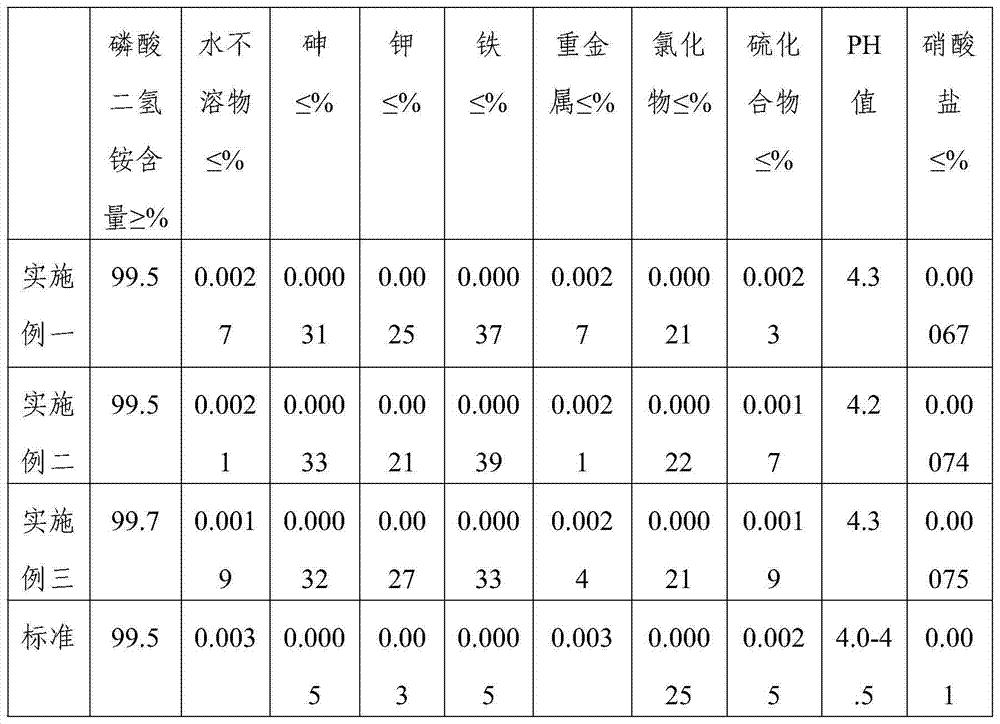

Embodiment 1

[0038] A method for preparing ammonium dihydrogen phosphate and co-producing a special enhanced fertilizer for onions, comprising the following steps:

[0039] (1) Preparation of intermediate: first add phosphoric acid to the reaction kettle, and raise the temperature of phosphoric acid to 120°C, then add carbonamide to the reaction kettle to make it react with phosphoric acid, after 240 minutes of reaction, cool down the temperature Crystallize after reaching 15°C, and then centrifuge to obtain the intermediate, the molar ratio of phosphoric acid to carbonamide is 1.1:1;

[0040] (2) Preparation of ammonium dihydrogen phosphate: the intermediate obtained in step (1) is sent into the reactor, and ammonia is passed into the reactor, and the mol ratio of ammonia to the intermediate is 1.4:1, and the reaction is controlled The time is 40min, the reaction temperature is 25°C, and the pH value is adjusted to 8. After the reaction is completed, the obtained slurry is added to the co...

Embodiment 2

[0045] A method for preparing ammonium dihydrogen phosphate and co-producing a special enhanced fertilizer for onions, comprising the following steps:

[0046] (1) Preparation of intermediate: first add phosphoric acid into the reaction kettle, and raise the temperature of phosphoric acid to 140°C, then add carbonamide into the reaction kettle to make it react with phosphoric acid, after 200 minutes of reaction, cool down the temperature crystallize after reaching 30°C, and then centrifuge to obtain the intermediate, the molar ratio of phosphoric acid to carbonamide is 1.3:1;

[0047] (2) Preparation of ammonium dihydrogen phosphate: the intermediate obtained in step (1) is sent into the reactor, and ammonia gas is passed into the reactor, the mol ratio of ammonia gas to the intermediate is 1.6:1, and the reaction is controlled The time is 60min, the reaction temperature is 15°C, and the pH value is adjusted to 9. After the reaction is completed, the obtained slurry is added t...

Embodiment 3

[0052] (1) Preparation of intermediate: first add phosphoric acid to the reaction kettle, and raise the temperature of phosphoric acid to 130°C, then add carbonamide to the reaction kettle to make it react with phosphoric acid, react for 220min, then cool down the temperature crystallize after reaching 20°C, and then centrifuge to obtain the intermediate, the molar ratio of phosphoric acid to carbonamide is 1.2:1;

[0053] (2) Preparation of ammonium dihydrogen phosphate: the intermediate obtained in step (1) is sent into the reactor, and ammonia is passed into the reactor, the mol ratio of ammonia to the intermediate is 1.5:1, and the reaction is controlled The time is 50min, the reaction temperature is 20°C, and the pH value is adjusted to 8.5. After the reaction is completed, the obtained slurry is added to the cooling crystallizer to circulate crystallization, and the filtrate is detected and analyzed at the same time. When the nitrogen and phosphorus pentoxide in the filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com