Flue gas hardness reducing apparatus and use method thereof

A flue gas and gas technology, applied in chemical instruments and methods, complex/solubilizer treatment, special treatment targets, etc., can solve the problems of high operating costs, large investment costs, and not being popularized and used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

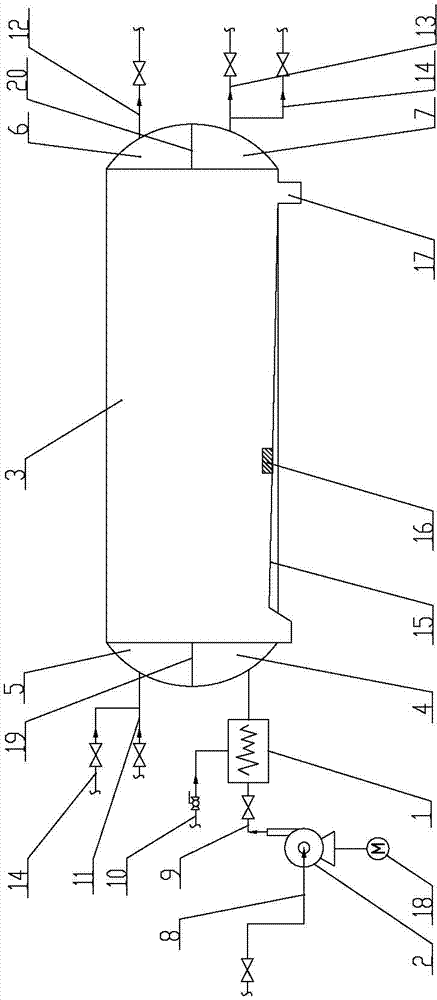

[0039] Embodiment one: as attached figure 1 As shown, the flue gas dehardening device includes a mixer 1, a fan 2 and a reactor 3. A shower is installed on the inside of the top of the reactor 3, and an air inlet connected to the reactor 3 is provided at the lower left end of the reactor 3. Chamber 4, the upper left end of the reactor 3 is provided with a water inlet chamber 5 communicated with the reactor 3, the upper right end of the reactor 3 is provided with an outlet chamber 6 communicated with the reactor 3, and the lower right end of the reactor 3 is provided with a The water outlet chamber 7 connected with the device 3, the air inlet of the fan 2 is equipped with a flue gas delivery pipe 8, the air outlet of the fan 2 is connected with the first inlet of the mixer 1 through the inlet pipe 9, and the second inlet of the mixer 1 is connected There is a dosing pipeline 10, the outlet of the mixer 1 communicates with the air inlet chamber 4, the water inlet pipeline 11 ...

Embodiment 2

[0047] Embodiment two: the using method of above-mentioned flue gas dehardening device, carry out according to the following steps:

[0048] In the first step, the sodium hydroxide solution or the ammonia solution is added to the inside of the mixer 1 through the dosing pipeline 10, and the flue gas is transported to the inside of the mixer 1 through the fan 2 and gasified with the sodium hydroxide solution or the ammonia solution. Liquid mixing, the working pressure inside the mixer 1 is in the range of 0.2MPa to 0.5MPa, and the pH value of the liquid after gas-liquid mixing is in the range of 9 to 10;

[0049] In the second step, the gas after the gas-liquid mixture enters the interior of the reactor 3 through the air inlet chamber 4 at the lower left end of the reactor 3, and the liquid after the gas-liquid mixture enters the inside of the reactor 3 through the air inlet chamber 4 at the lower left end of the reactor 3, and waits to be softened The water body enters t...

Embodiment 3

[0050] Embodiment three: the use method of above-mentioned flue gas dehardening device, carry out according to the following steps:

[0051] In the first step, the sodium hydroxide solution or the ammonia solution is added to the inside of the mixer 1 through the dosing pipeline 10, and the flue gas is transported to the inside of the mixer 1 through the fan 2 and gasified with the sodium hydroxide solution or the ammonia solution. Liquid mixing, the working pressure inside the mixer 1 is in the range of 0.2MPa to 0.5MPa, and the pH value of the liquid after gas-liquid mixing is in the range of 9 to 10;

[0052] In the second step, the gas after the gas-liquid mixture enters the interior of the reactor 3 through the air inlet chamber 4 at the lower left end of the reactor 3, and the liquid after the gas-liquid mixture enters the inside of the reactor 3 through the air inlet chamber 4 at the lower left end of the reactor 3, and waits to be softened The water body enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com