A method for manufacturing a large-size bend-insensitive multimode optical fiber preform

A bend-insensitive, optical fiber preform technology, used in manufacturing tools, glass manufacturing equipment, etc., can solve problems such as bend insensitivity, reduce costs, optimize DMD and bandwidth performance, and reduce impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with embodiment.

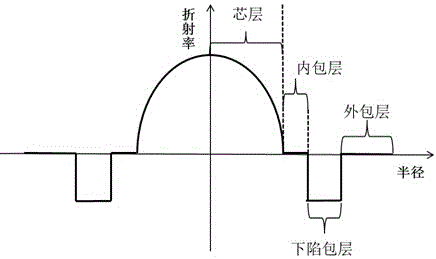

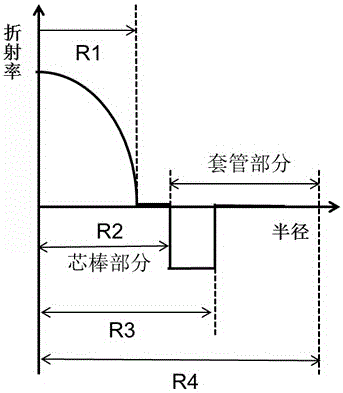

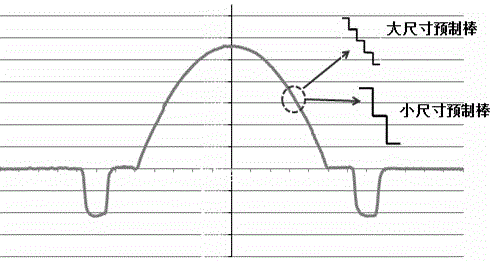

[0064] The optical fiber core rod is prepared by the PCVD process. The liner used is a pure silica glass liner. The liner is cleaned and fully dried before deposition. First, the pure silica glass liner is used as the core rod substrate tube, and the doping is deposited by the PCVD process. The deposited liner is melted and shrunk into a solid mandrel in an electric heating furnace, and the solid mandrel is corroded, cleaned, and dried for use, and then the pure quartz glass liner is used as the bushing base tube, and the process is carried out by PCVD process. Doping deposition, clean and corrode the doped sleeve after deposition; finally insert the solid core rod into the doped sleeve to make optical fiber preform for RIT process, core rod, sleeve, preform The main parameters are shown in Table 1; the RIT process preform is directly drawn, two layers of optical fiber coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com