Cement-based wave absorption material doped with iron tailings and preparation method of cement-based wave absorption material

A technology of wave-absorbing materials and iron tailings, which is applied in the interdisciplinary field of electromagnetism and material science, can solve the problems of no absorption and high cost of cement-based wave-absorbing materials, reduce preparation costs, realize resource reuse, and low prices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

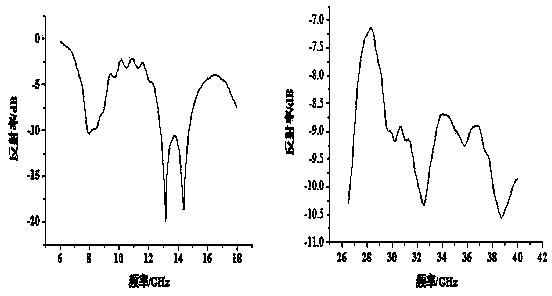

Embodiment 1

[0038] The ratio of each raw material in this embodiment is as follows: the weight ratio of ordinary Portland cement to silica fume, quartz sand, iron tailings, water reducing agent, air-entraining agent, and water is 440:60:810:540:0.5: 0.015:250.

[0039] Its preparation method comprises the following steps:

[0040] 1) Weigh the raw materials according to the ratio of each raw material, and set aside.

[0041] 2) Mix and stir the required amount of cement and silica fume to obtain the mixed dry material 1.

[0042] 3) Mix and stir the required amount of quartz sand and iron tailings evenly to obtain mixed dry material 2.

[0043] 4) Add the required amount of water reducing agent and air entraining agent into the water, and stir evenly to obtain a mixed solution.

[0044] 5) Add mixed dry material 1 to the mixture prepared above and stir. After stirring for 30 seconds, add mixed dry material 2 into it, and continue stirring until the mixture is uniform.

[0045] 6) Pour...

Embodiment 2

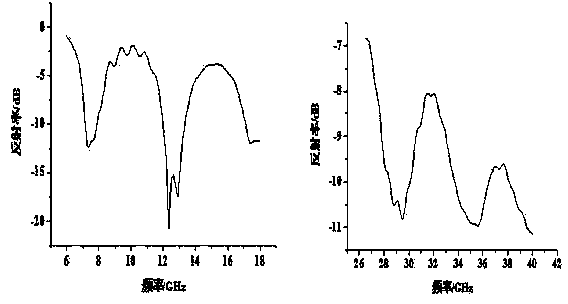

[0049] The ratio of each raw material in this embodiment is as follows: the weight ratio of ordinary Portland cement to silica fume, quartz sand, iron tailings, water reducing agent, air-entraining agent, and water is 460:20:270:1080:2.5: 0.035:250.

[0050] Its preparation method comprises the following steps:

[0051] 1) Weigh the raw materials according to the ratio of each raw material, and set aside.

[0052] 2) Mix and stir the required amount of cement and silica fume to obtain the mixed dry material 1.

[0053] 3) Mix and stir the required amount of quartz sand and iron tailings evenly to obtain mixed dry material 2.

[0054] 4) Add the required amount of water reducing agent and air entraining agent into the water, and stir evenly to obtain a mixed solution.

[0055] 5) Add mixed dry material 1 to the mixture prepared above and stir. After stirring for 30 seconds, add mixed dry material 2 into it, and continue stirring until the mixture is uniform.

[0056] 6) Pou...

Embodiment 3

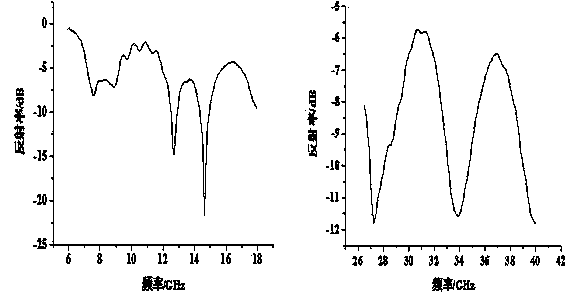

[0060] The ratio of each raw material in this embodiment is as follows: the weight ratio of ordinary Portland cement to silica fume, quartz sand, iron tailings, water reducing agent, air-entraining agent, and water is 480:40:0:1350:3: 0.05:250.

[0061] Its preparation method comprises the following steps:

[0062] 1) Weigh the raw materials according to the ratio of each raw material, and set aside.

[0063] 2) Mix and stir the required amount of cement and silica fume to obtain the mixed dry material 1.

[0064] 3) Mix and stir the required amount of quartz sand and iron tailings evenly to obtain mixed dry material 2.

[0065] 4) Add the required amount of water reducing agent and air entraining agent into the water, and stir evenly to obtain a mixed solution.

[0066] 5) Add mixed dry material 1 to the mixture prepared above and stir. After stirring for 30 seconds, add mixed dry material 2 into it, and continue stirring until the mixture is uniform.

[0067] 6) Pour the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com