Roof greening culture substrate and preparation method thereof

A cultivation substrate and roof greening technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of high transportation costs, high material prices, high prices, etc. The effect of expansive and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation of roof greening cultivation substrate

[0028]First, the landscaping waste is crushed into particles with an average particle size of 1-10mm with a pulverizer, and the basic physical and chemical properties such as pH, carbon-nitrogen mass ratio and water content of the landscaping waste and municipal domestic sludge are tested and analyzed respectively, and the landscaping waste Waste (12kg) and municipal domestic sludge (10kg) were mixed evenly, and the moisture content was adjusted to 61%, and the carbon-to-nitrogen mass ratio was 25, and forced ventilation aerobic composting was carried out;

[0029] Carry out aerobic composting in the aerobic composting reactor, the heap body is 80L (increasing heat preservation measures in winter), forced interval ventilation oxygen supply, control ventilation rate 250L / H, ventilation mode is to pass 10 minutes, stop 50 minutes, with this as One cycle, continuous circulation and ventilation for 30 da...

Embodiment 2

[0032] Embodiment 2: the comparative experiment of roof greening cultivation substrate

[0033] The roof greening cultivation substrate prepared in Example 1 and peat, garden soil (grinding through 2mm sieve hole) perlite, coal cinder, plant ash are combined to form 9 kinds of planting substrates, and the substrates are mixed by volume. The specific ratio is as follows:

[0034] Table 1 Comparison test of different planting substrates

[0035]

[0036]

[0037] Put 9 kinds of substrates in 50×50cm planting boxes respectively, each planting substrate has a thickness of 7cm, and each planting box is planted with 7cm-cut S. Line, a total of 215 species. Water once a day around 2:30 p.m., the amount of water is the amount of water evaporated the day before (weigh the total weight of the planting box before each watering), and the planting time is 37 days.

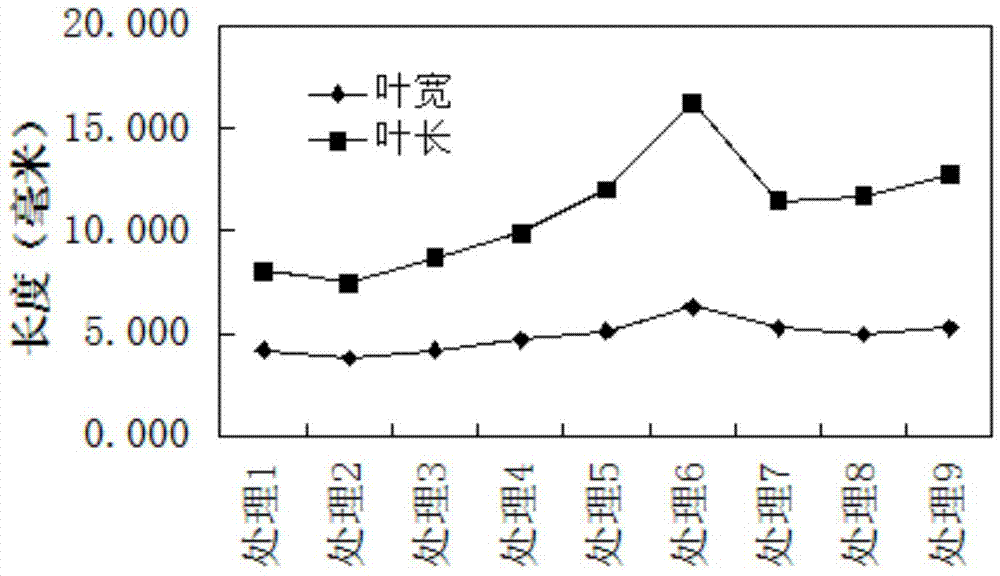

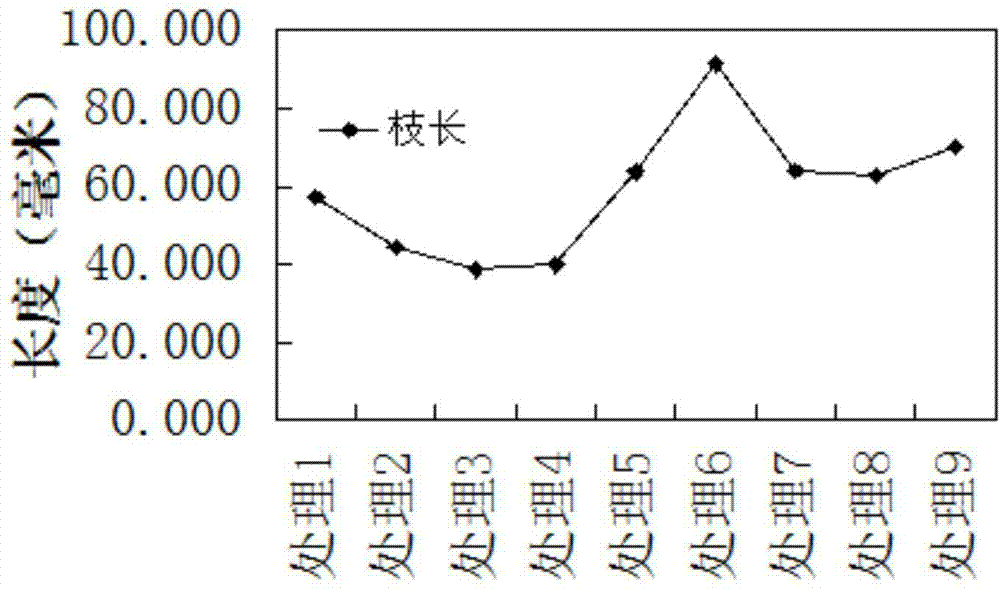

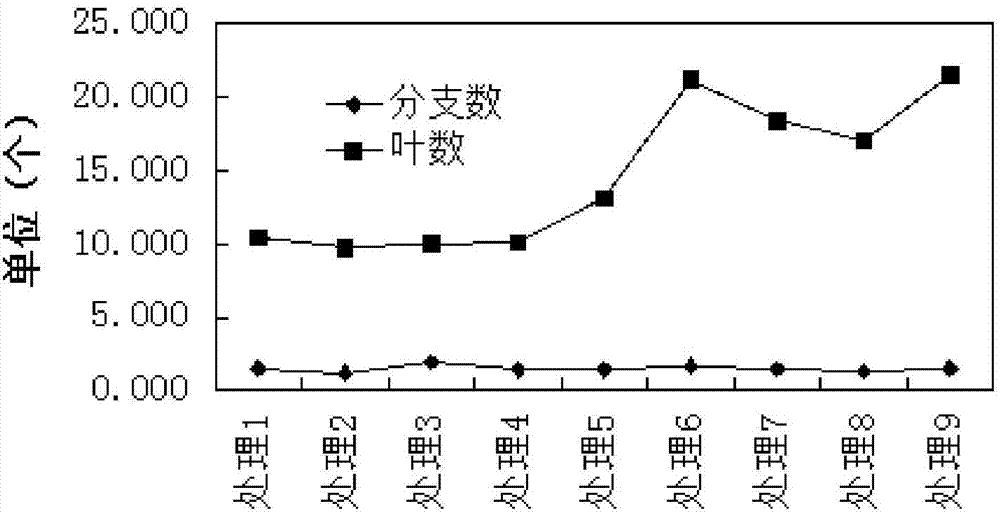

[0038] The results of the planting experiment showed that the physical indicators of compost:perlite=5:1 were superi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com