Ultrasonic roller washing machine and clothes cleaning method

A drum washing machine and ultrasonic technology, applied in the field of washing machines, can solve the problems that the detergent cannot be completely dissolved and effectively removed, and the washing effect is not obvious, so as to reduce the amount of washing liquid and washing water, save the number of rinsing, and improve the cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The traditional washing machine uses too much detergent to achieve the purpose of decontamination and bacteria removal during the washing process. Because the detergent is difficult to fully dissolve and cannot fully exert the decontamination effect of the detergent, it is difficult to completely remove some stubborn stains, and it is too Too much detergent will pollute the environment, and cause the problem of more times of rinsing, waste water and electricity, cannot guarantee that the clothes are rinsed thoroughly, and the washing effect is often unsatisfactory.

[0030] Aiming at the deficiencies in the prior art, the present invention provides an ultrasonic drum washing machine and a clothes cleaning method, which can effectively remove stubborn stains on the clothes and at the same time effectively sterilize them, reduce the amount of detergent used and the number of times of washing, and To achieve the purpose of energy saving.

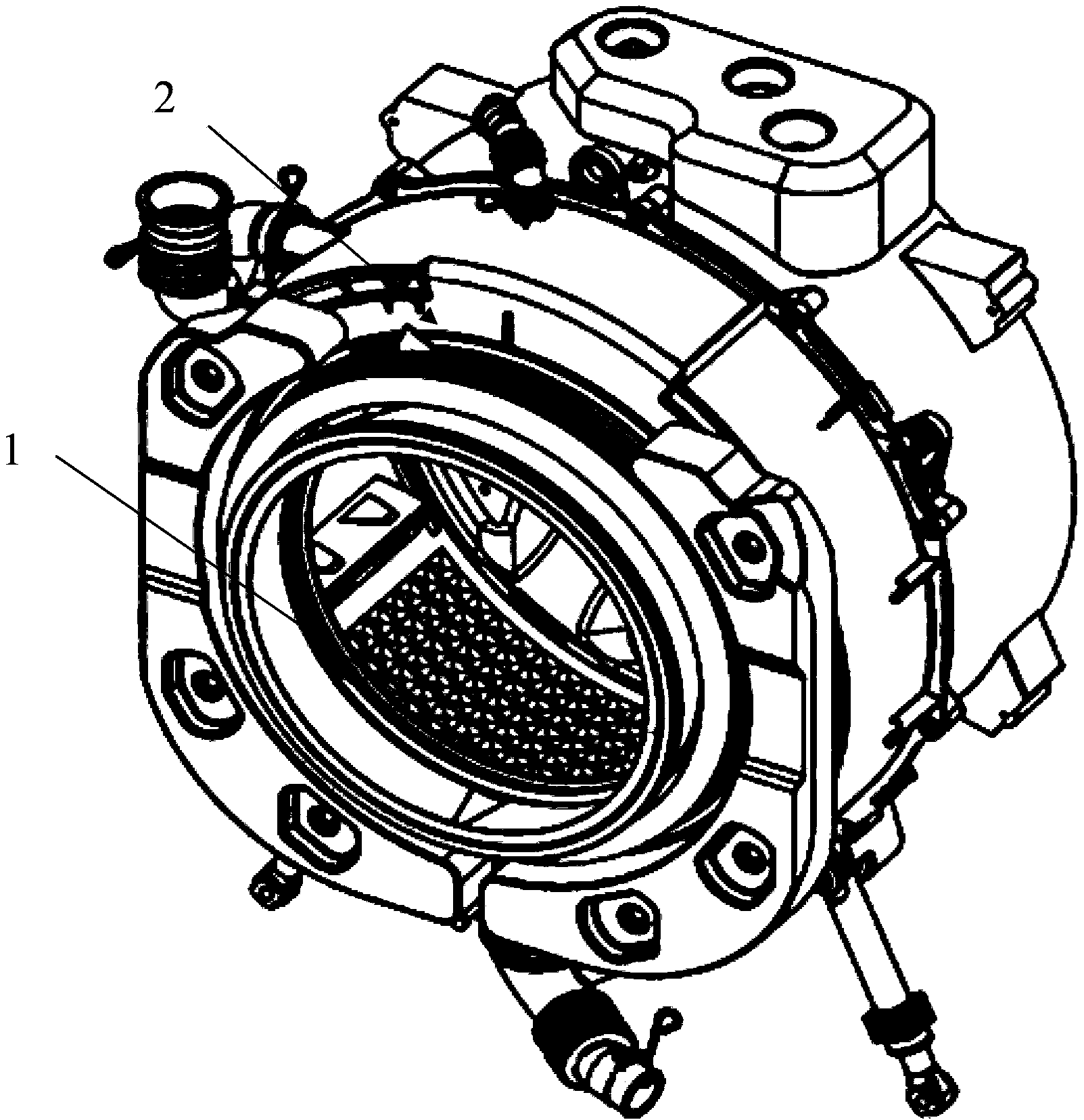

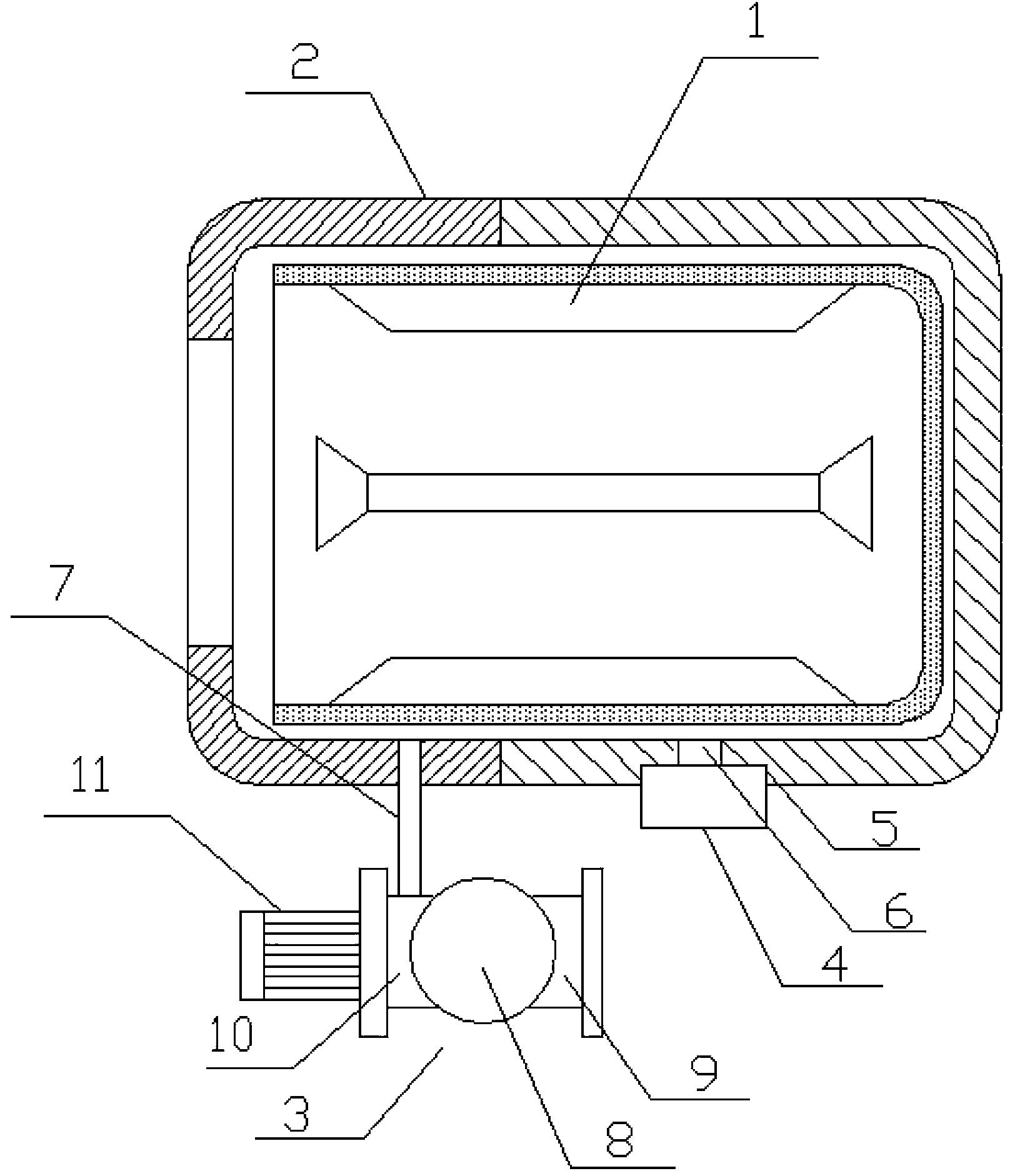

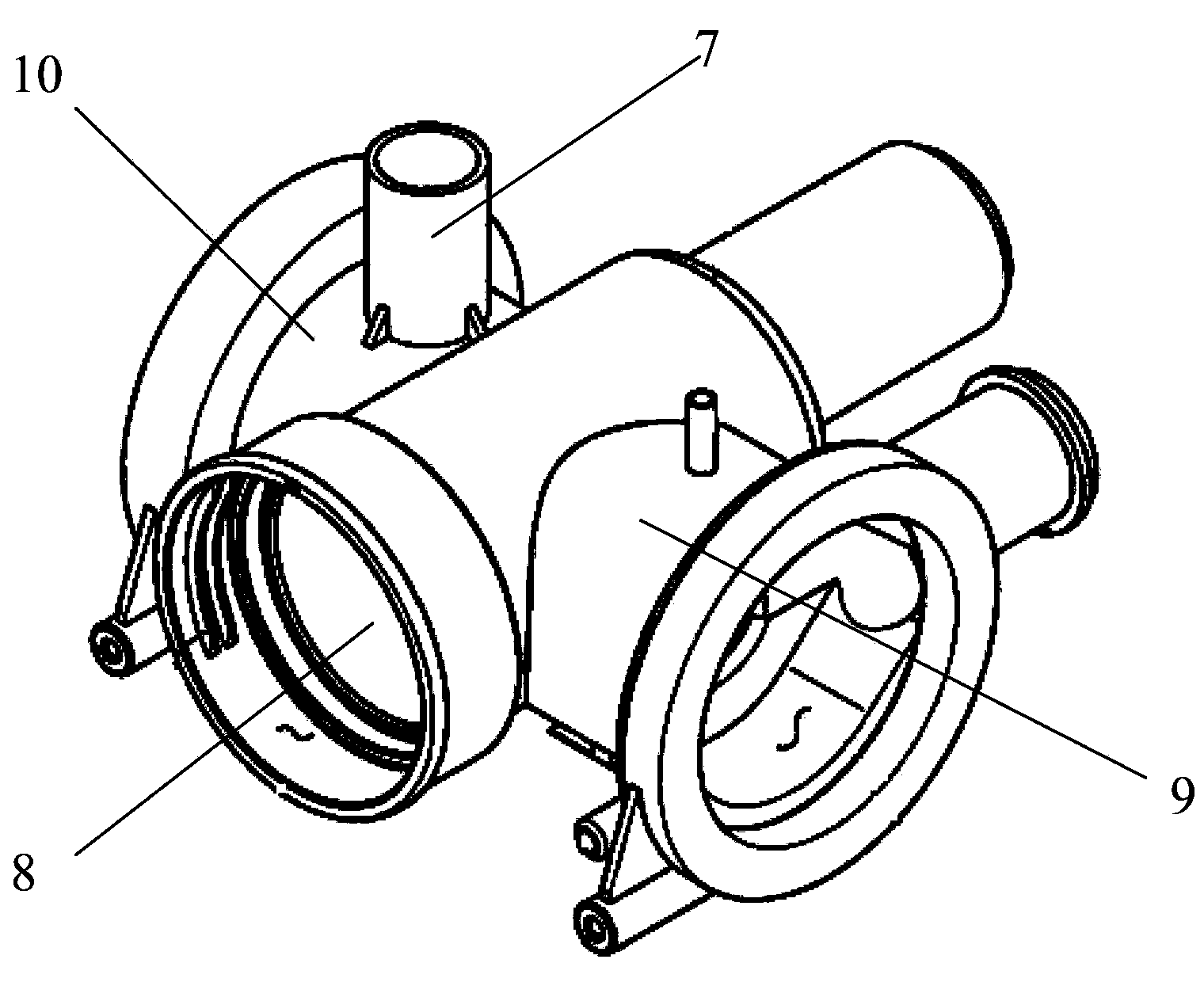

[0031] The technical solutions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com