System and method for determining explosion suppression performance of liquid fuel vapor by water vapor

A liquid fuel and measurement system technology, applied in the direction of material explosion, can solve the problem of insufficient reaction of hydrocarbons, and achieve the effect of ensuring speed and accuracy, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

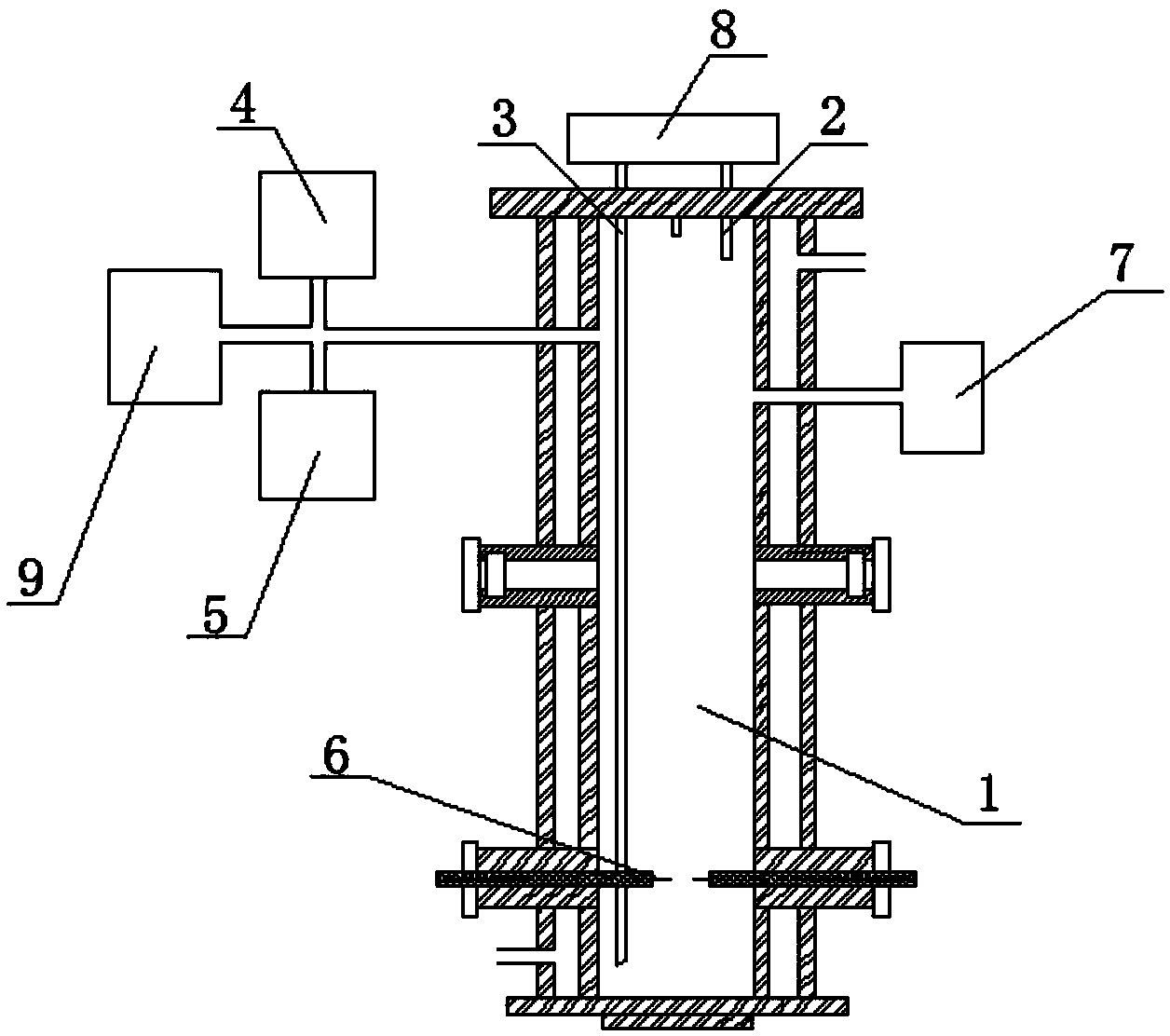

[0059] Such as figure 1 As shown, a water vapor anti-explosion performance measurement system for liquid fuel vapor includes an explosion chamber 1, a computer, a main control system and a first vacuum device 7 connected thereto, a gas circulation device 8, and a liquid fuel vapor supply device 4 , dry air supply device 5, water vapor supply device 9 and ignition device; described explosion chamber 1 is a closed hollow tubular structure, and the hollow part of described explosion chamber 2 is an explosion space, and a point is installed at the beginning of described explosion chamber 1 The fire electrode 6 is equipped with an explosion chamber pressure sensing device at the end, the ignition electrode 6 is connected with the ignition device, and the explosion chamber pressure sensing device is connected with the main control system; the liquid fuel supply device 4. The dry air supply device 5, the steam supply device 9 and the first vacuum device 7 are all connected to the exp...

Embodiment 2

[0069] A method for measuring the anti-knock performance of water vapor to liquid fuel vapor using the water vapor detonation suppression performance measurement system for liquid fuel vapor described in Example 1, comprising the steps of:

[0070] A. Use the first vacuuming device 7 to evacuate the explosion space, then pass liquid fuel vapor into the explosion space with the liquid fuel vapor supply device 4, and pass water vapor into the explosion space with the water vapor supply device 9 And use the dry air supply device 5 to inject dry air therein until the internal pressure of the explosion space is a standard atmospheric pressure; open the gas circulation device 8 to mix the liquid fuel vapor, water vapor and dry air to obtain a mixed gas;

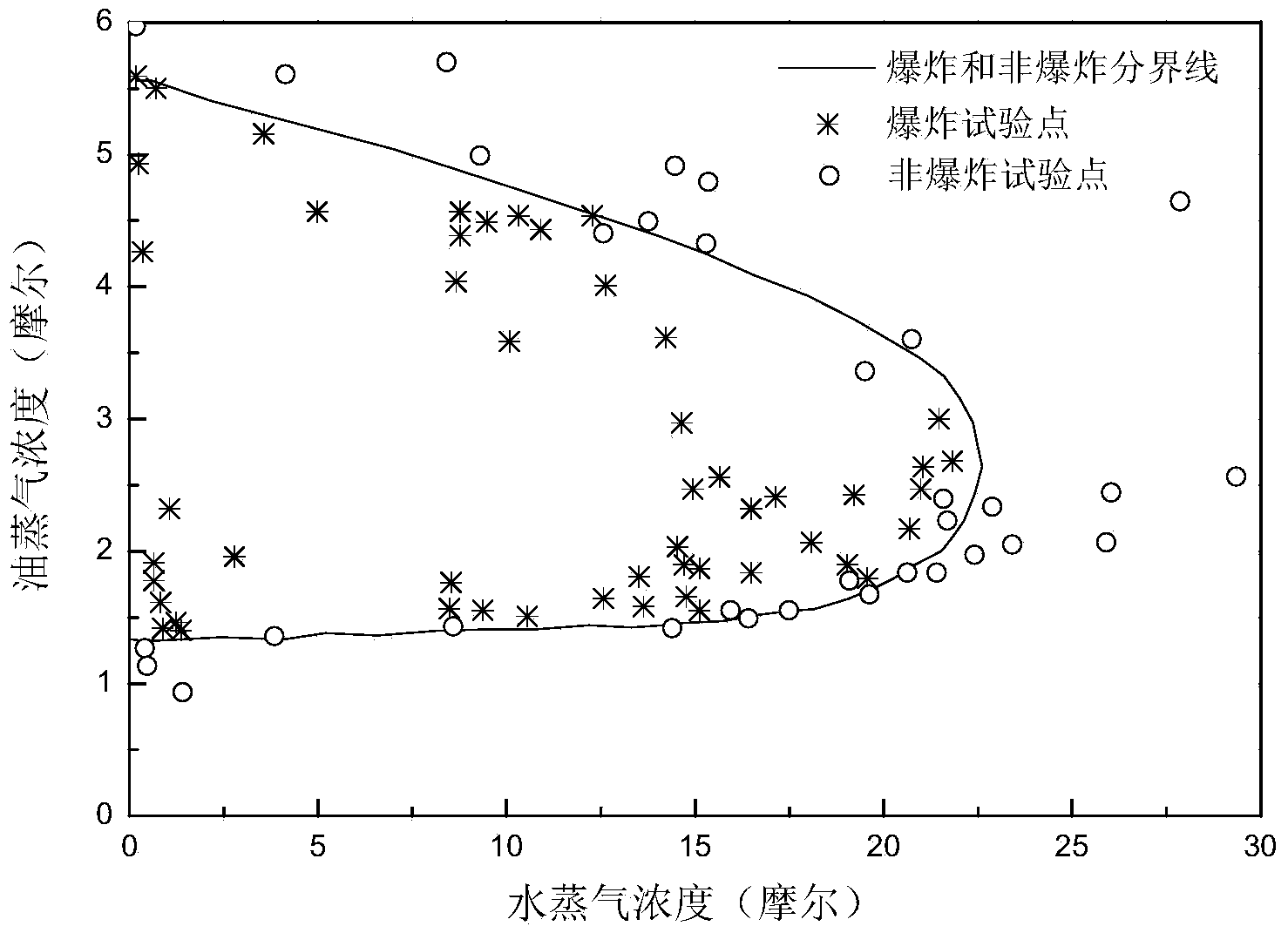

[0071] B. detonate the mixed gas by ignition device and ignition electrode 6; the explosion chamber pressure sensing device transmits the measured explosion pressure data to the computer, and compares the measured explosion pressure...

Embodiment 3

[0074] A method for measuring the anti-knock performance of water vapor to liquid fuel vapor using the water vapor detonation suppression performance measurement system for liquid fuel vapor described in Example 1, comprising the steps of:

[0075] A, use the first vacuum device 7 to evacuate the explosion space to a vacuum degree of 0.8KPa; inject constant temperature water into the interlayer constant temperature structure of the side wall of the explosion chamber 1 with a constant temperature water supply device, the temperature of the constant temperature water 90°C;

[0076] Using the liquid fuel vapor supply device 4 to prepare the liquid fuel vapor specifically includes the following steps:

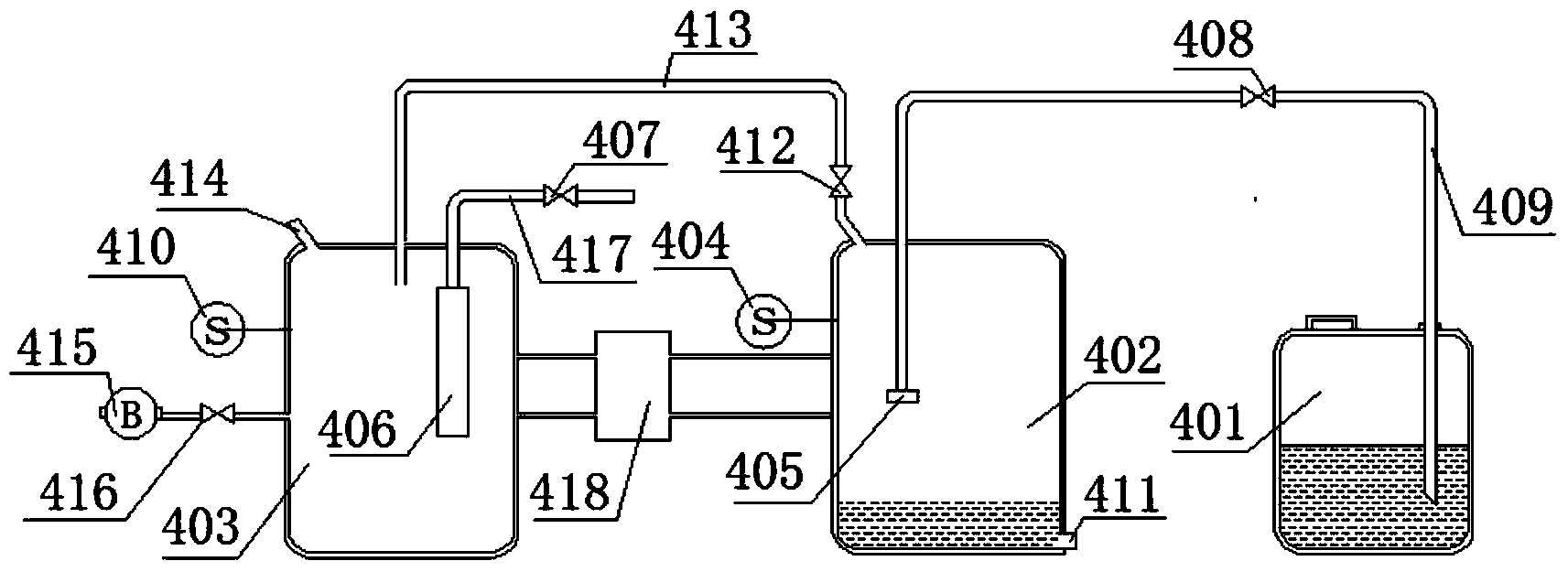

[0077] Turn on the second vacuum device 415 to evacuate the steam generation tank 402 and the steam storage tank 403 to a vacuum degree of 0.75-1.5Kpa, then close the second vacuum device 415 and close the air supply control Valve 412, open the constant temperature water supply de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com