Industrial robot three-dimensional real-time and high-precision positioning device and method

An industrial robot and positioning device technology, applied in three-dimensional position/channel control and other directions, can solve the problems that affect the work efficiency of industrial robots, hinder the development of industrial robots, and have large calibration errors, and achieve high positioning accuracy, high positioning accuracy, and easy operation. Effect

Active Publication Date: 2015-01-21

南京赫曼机器人自动化有限公司

View PDF10 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] To sum up, the current three-dimensional positioning method of robots in industrial production has the following disadvantages: the system needs to be calibrated during the positioning process, the calibration error is large, the operation is complicated, and the positioning accuracy is low, which affects the work efficiency of industrial robots and hinders the development of industrial robots. development of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0105] Using the three-dimensional real-time high-precision positioning method for industrial robots based on the active camera unit, 21 repeated three-dimensional real-time positioning experiments for industrial robots have been carried out under the device of the present invention. The method has high positioning accuracy, with an average error of 0.2989mm.

[0106] Table 2

[0107]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

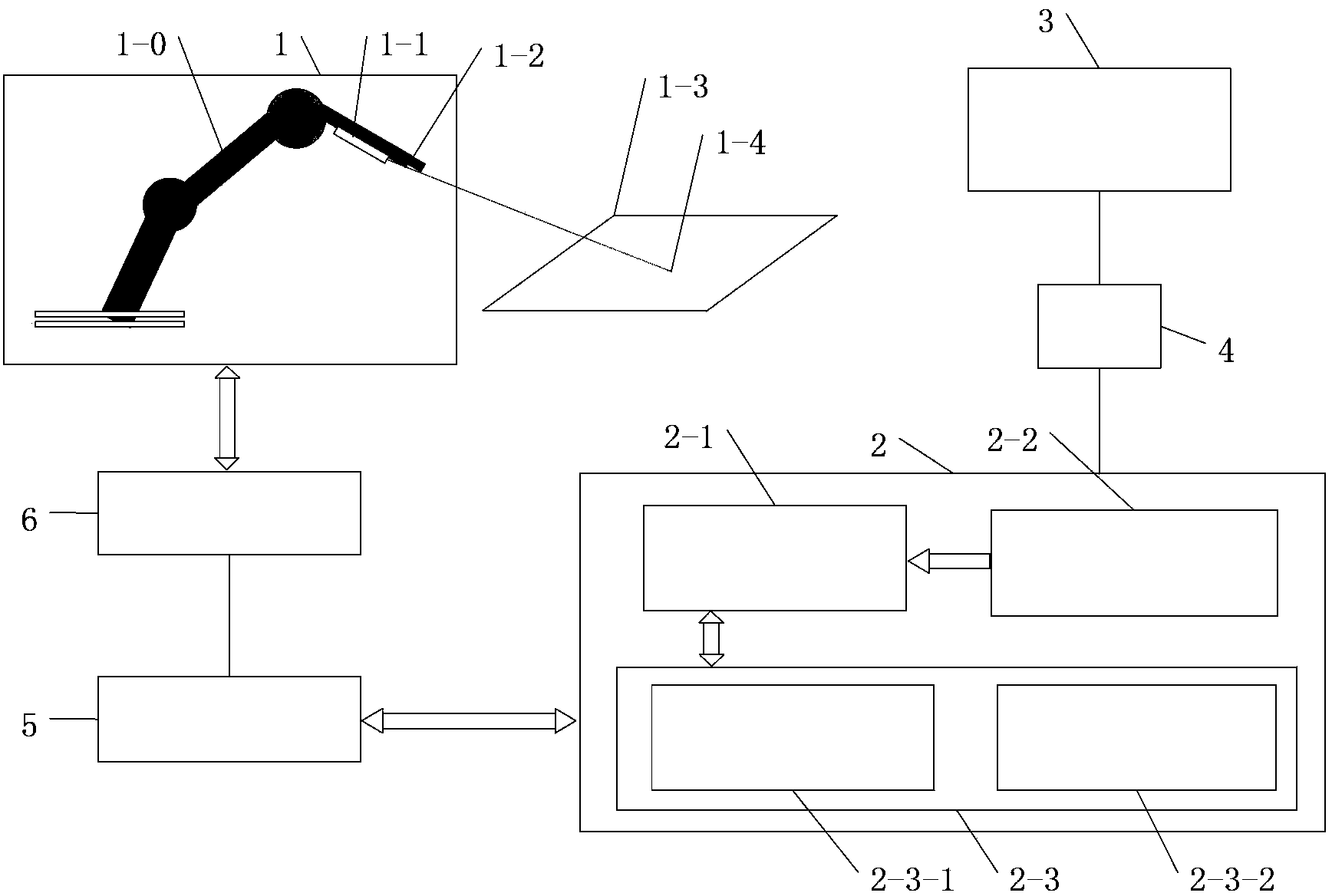

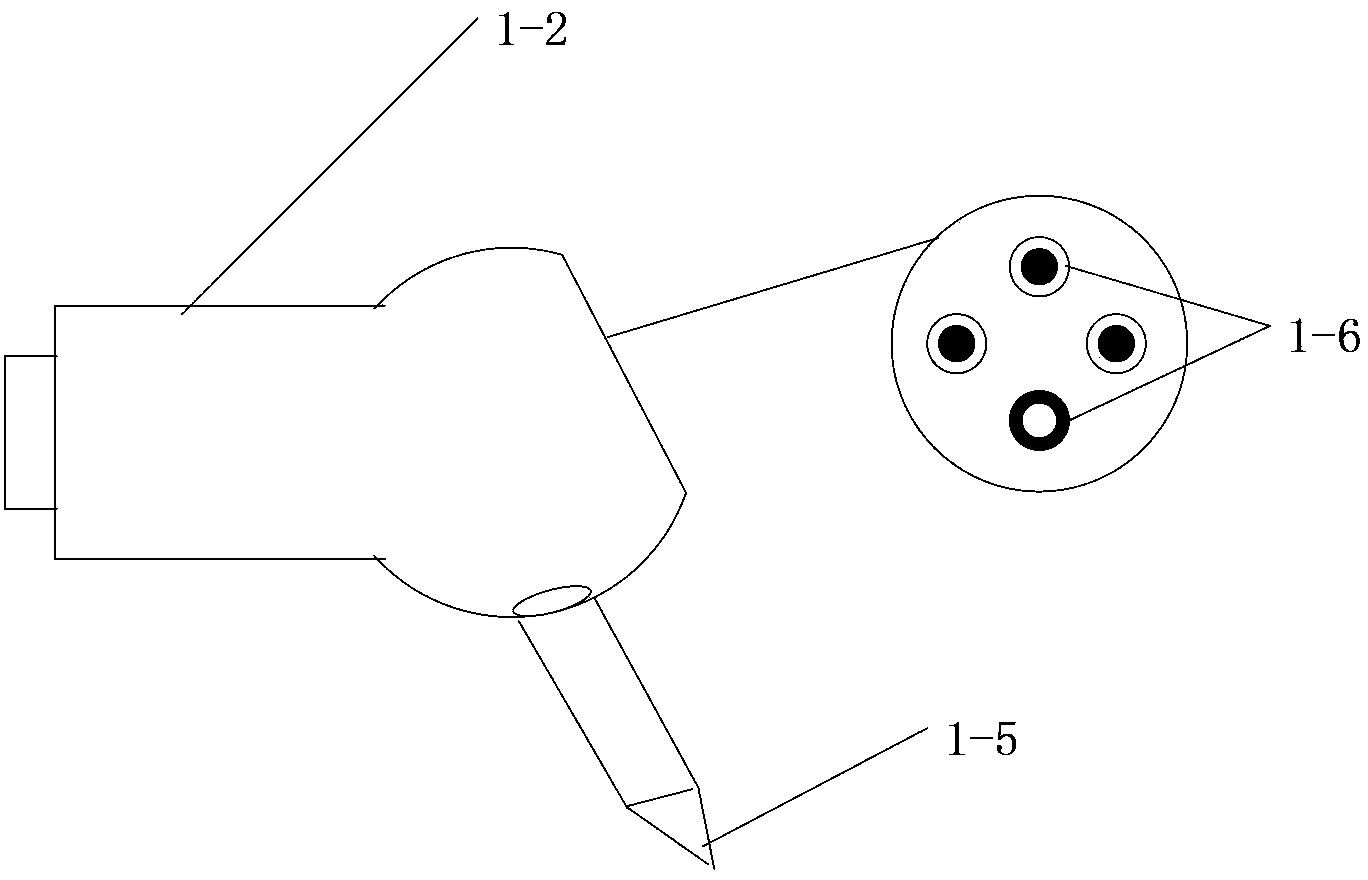

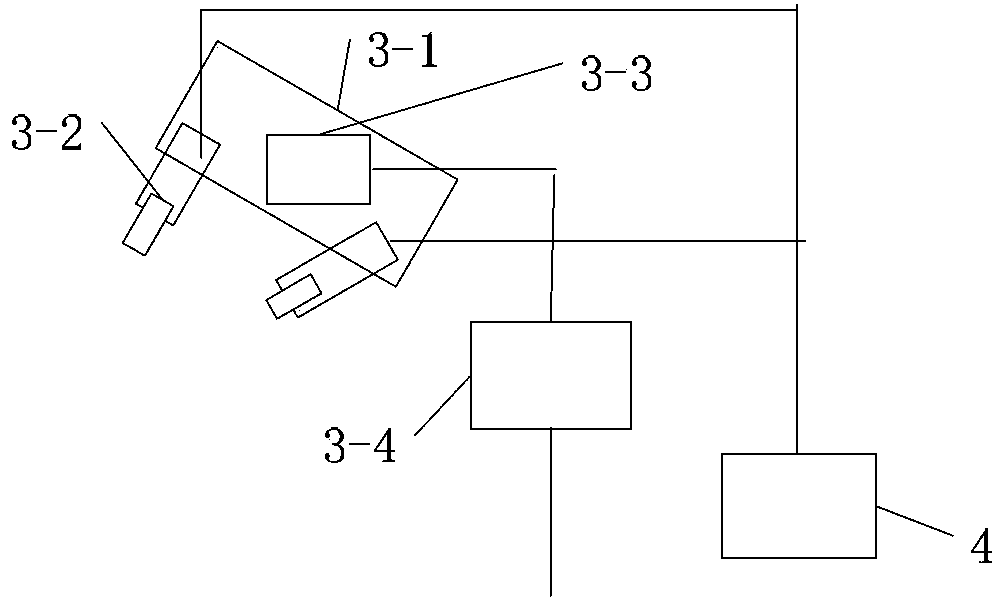

The invention discloses an industrial robot three-dimensional real-time and high-precision positioning device and method. The device comprises an industrial robot system, an industrial computer and a camera unit, wherein the industrial computer is connected with the industrial robot controller through a first gigabyte Ethernet, and then is connected into the industrial robot system, the industrial computer is connected with the camera unit through a second gigabyte Ethernet, and the camera unit is an active camera unit or a multi-camera unit. The method includes the following steps that: the position state of the camera unit is set according to the positions of a feature point and an actual target point; a mapping relationship of three-dimensional coordinates in a robot space and two-dimensional coordinates in a camera space is established; the position of a target point in the three-dimensional robot space is obtained, the industrial robot controller sends a command so as to control a robot to move to the target point and position the robot on the target point; and finally, the robot is positioned on the actual target point through judgment. The industrial robot three-dimensional real-time and high-precision positioning device and method of the invention have the advantages of no need for calibration, high precision, wide field of vision and high real-time performance.

Description

technical field [0001] The invention relates to the technical field of industrial robot visual servoing, in particular to a three-dimensional real-time high-precision positioning device and method for an industrial robot. Background technique [0002] With the expansion of the application range of industrial robots and the needs of various complex occasions, the visual servo of industrial robots is becoming more and more important. In the current practical application of industrial robots, due to problems such as positioning accuracy, real-time performance, and the need for calibration, only a few occasions use robot visual servo positioning. With the development of the industrial robot industry, it will be an inevitable trend for industrial robots to have visual servo capabilities. . Real-time performance and positioning accuracy are the two most important indicators to verify the effectiveness and practicability of a robot vision positioning system, and are also key facto...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G05D1/10

Inventor 刘永时定兵

Owner 南京赫曼机器人自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com