Powder compositions of a complex between an acid and a metal and method for preparing same

A compound and metal technology, which is applied in the preparation of organic compounds, cyanide reaction preparation, compounds of Group 7/17 elements of the periodic table, etc., can solve problems such as equipment blockage and inability to allow high dry extracts of reaction mixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

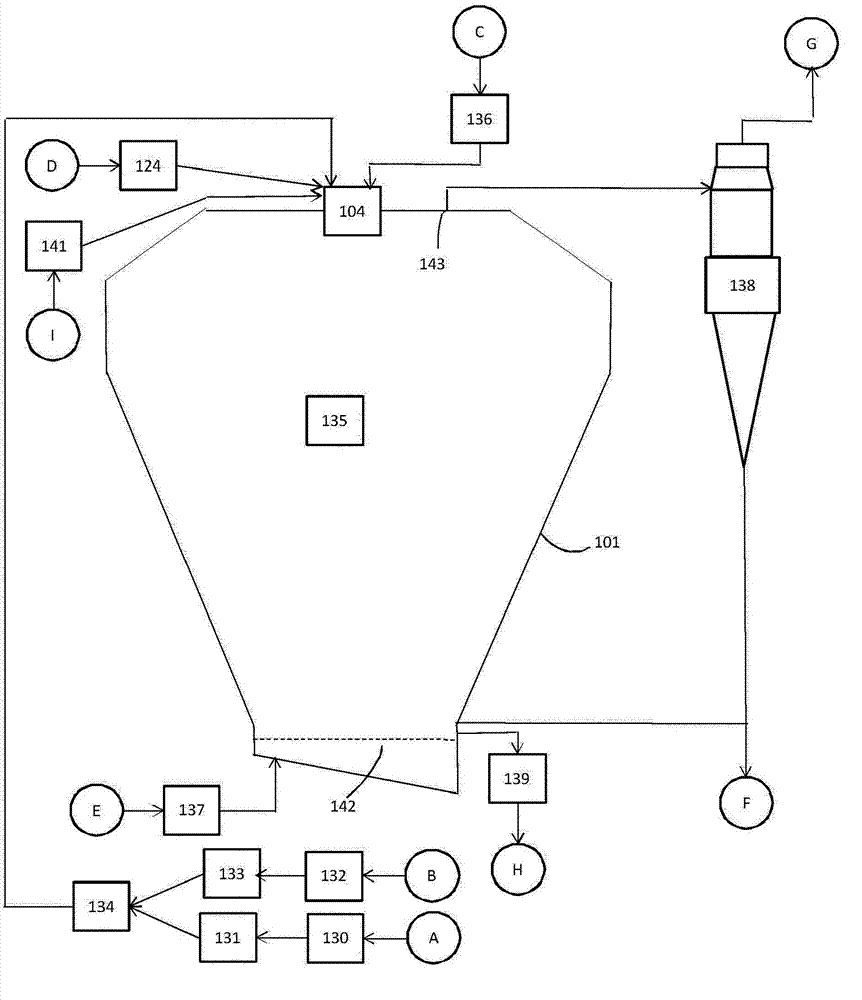

Method used

Image

Examples

Embodiment 1

[0262] Example 1: Salt (HMTBA) 2 Preparation of Ca

[0263] Milk of lime prepared at 30% dry matter was mixed with HMTBA solution having 88% dry matter in a pipeline containing a static mixer with 22.2% milk of lime (based on dry matter used) and 77.8% HMTBA (based on dry matter used). Substance calculation) ratio continuous mixing.

[0264] The contact time was 7 seconds.

[0265] The reaction mixture was then pulverized in a single-effect atomization tower with an inlet temperature of 140°C and an outlet temperature of 79°C by means of nozzles known to those skilled in the art.

[0266] The product was then processed in a fluidized air bed dryer to obtain an agglomerated powder to simulate a multiple effect atomization tower.

[0267] The resulting product has a HMTBA content of 81.4%, a Ca of 11.8% 2+ and a water content of 1.3%. The average particle size was 240 μm and the density was 300 g / L.

Embodiment 2

[0268] Example 2: Salt (HMTBA) 2 Another preparation of Ca

[0269] Milk of lime prepared at 30% dry matter was continuously mixed at 138 kg / H with a 154 Kg / H HMTBA solution with 88% dry matter in a pipeline containing a static mixer to obtain a reaction mixture with 60% dry matter.

[0270] The contact time was 15 seconds.

[0271] The reaction mixture was then pulverized in a single-effect atomization tower with an inlet temperature of 185°C and an outlet temperature of 128°C by means of nozzles known to those skilled in the art.

[0272] The resulting product contained 84.9% HMTBA, 12.0% Ca 2+ and 0.5% water.

[0273] The average particle size was 156 μm (Dv(0.5) by laser granulometry) and the density was 170 g / l.

Embodiment 3

[0274] Embodiment 3: the preparation of the Mg salt of HMTBA

[0275] The magnesium hydroxide suspension with 20% dry matter was continuously mixed at 2.9 kg / H with a 4.3 Kg / H HMTBA solution with 70% dry matter in a line containing a static mixer.

[0276] The contact time in reactive atomization was 7 seconds.

[0277] The reaction mixture was then pulverized in a single-effect atomization tower with an inlet temperature of 140°C and an outlet temperature of 76°C by means of nozzles known to those skilled in the art.

[0278] The resulting product had a HMTBA content of 91.2%, a Mg of 7.4% 2+ and a water content of 1.4%.

[0279] The average particle size was 7 μm and the density was 310 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| liquidity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com