Process for producing volatile organic compounds from biomass material

A technology of biomass materials and organic compounds, applied in the preparation of organic compounds, biochemical equipment and methods, separation/purification of hydroxyl compounds, etc., can solve the problems of low storage efficiency and expensive storage, and achieve the goal of eliminating demand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

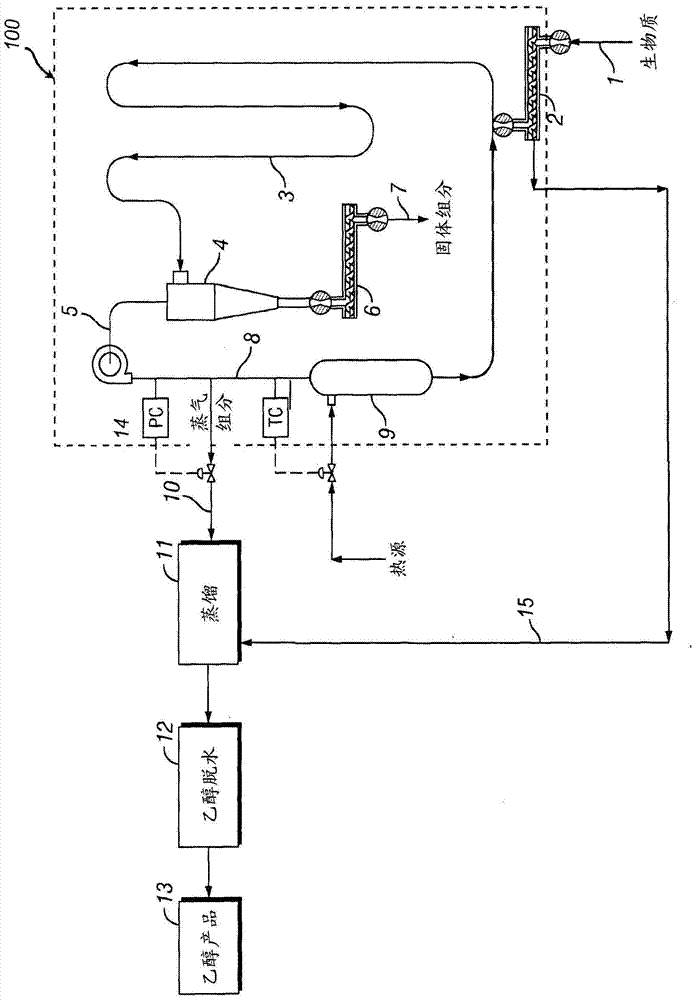

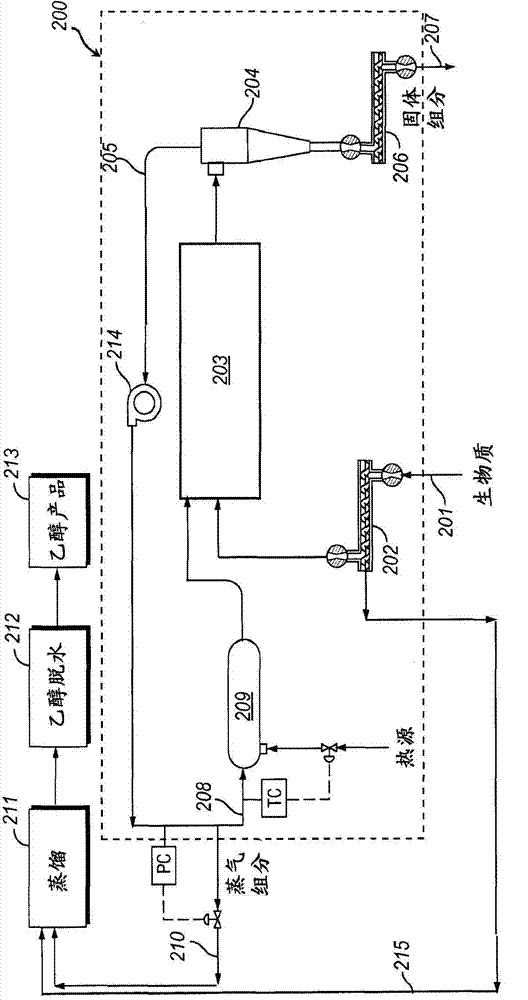

Method used

Image

Examples

Embodiment A

[0128] In this example, various samples of fresh chopped sorghum were mixed with various added components listed in Table A.1 and stored in silage lines for 258 days. The amount of ethanol produced in each experiment is shown in the bottom row of the table. Addition rates for selected additives are shown in Table A.2.

[0129]

[0130] Table A.2

[0131] additive rate

[0132] The experiments of example A demonstrate the principle of ethanol production in silage stacks and the duration of this storage, furthermore they demonstrate the influence of certain additives. All cases produced significant amounts of ethanol in this example, showing that embodiments of the invention can be quite robust. In Table A.1, all but the last row describe which additives were entered into the test. The bottom row depicts the results of ethanol production in this experiment. In general, experiments with acid indicated superior stability relative to those without acid. Neverthele...

Embodiment B

[0134]In Example B, three additional experiments are shown in Table B.1. Addition rates for selected additives are shown in Table B.2.

[0135] Table B.1

[0136]

[0137]

[0138] Table B.2

[0139] Additives

[0140] The experiments in Example B also demonstrate the effect of certain additives as well as the effect of scale. Experiments 1 and 2 of Example B were performed in the same tank to demonstrate that this fermentation technique is stable and efficient on a commercial scale.

Embodiment C

[0142] In these experiments, GEA SSD TM Used as a solvent-free recovery unit. In Table C.1 below, the top section describes certain properties of the prepared biomass material fed into the system. The next section describes the conditions for the solid components leaving the solvent less recovery system. The third section shows the operating conditions of the solvent-less recovery system and the last section gives the recovery rates of the main liquid components: ethanol, acetic acid and water. Shown here is the ability to recover >90% ethanol in the solids in all cases (100% in some cases), and the ability to vary the amount of ethanol and water recovered based on the conditions of the solvent-less recovery system. Samples 10, 11 and 12 below also contained significant amounts of acetic acid and show that this method can also be used to recover acetic acid efficiently.

[0143]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com