Factory type production system of sprouting vegetable

A production system and technology for sprouts, which are applied in the field of sprout factory production systems, can solve problems such as wasting water resources, low work efficiency, and inapplicability, and achieve safe food, efficient cleaning and sorting, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

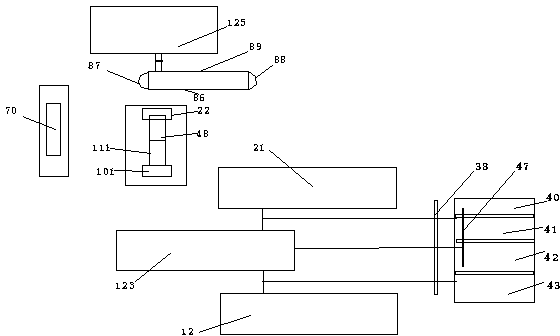

[0051] Example 1, such as figure 1 Shown, a kind of industrialized production system of sprouted vegetables, this system comprises: industrialized seed disinfection space 123 of sprouted vegetables, soaking space 12 of industrialized seeds of sprouted vegetables, industrialized spraying space 21 of sprouted vegetables, finished sprouts Vegetable material distribution space 124, finished product sprout vegetable inventory space 125, described sprout vegetable industrialization seed disinfection space 123, sprout vegetable industrialization seed soaking space 12, sprout vegetable industrialization spraying space 21 is provided with In a water-saving circulation production system, the sprout vegetable storage space 125 is provided with a cleaning device for the sprout vegetable basket and a roller conveyor structure for the sprout vegetable basket,

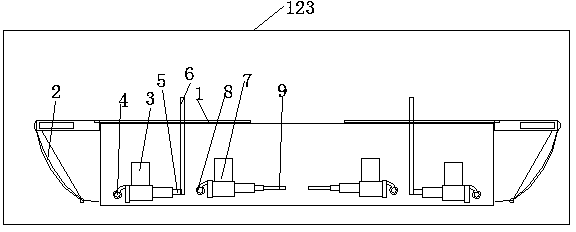

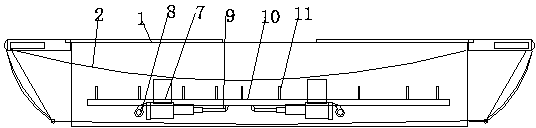

[0052] like figure 2 , 3 As shown, the seed disinfection tank 123 of industrialized seed disinfection space 123 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com