Solid-state alcohol preservative and manufacturing method thereof

A technology of solid alcohol and a production method, applied in the field of food additives, can solve the problems of low alcohol content, heavy alcohol taste, and inability to package, and achieve the effects of increasing alcohol content, stable volatilization rate, and reducing packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A solid alcohol antistaling agent, comprising 3 parts by weight of stearic acid, 0.6 parts of sodium hydroxide, 1 part of allyl isothiocyanate, 5 parts of powder carrier, 100 parts of edible alcohol and 0.2 parts of essence and fragrance; Wherein the powder carrier is pregelatinized starch.

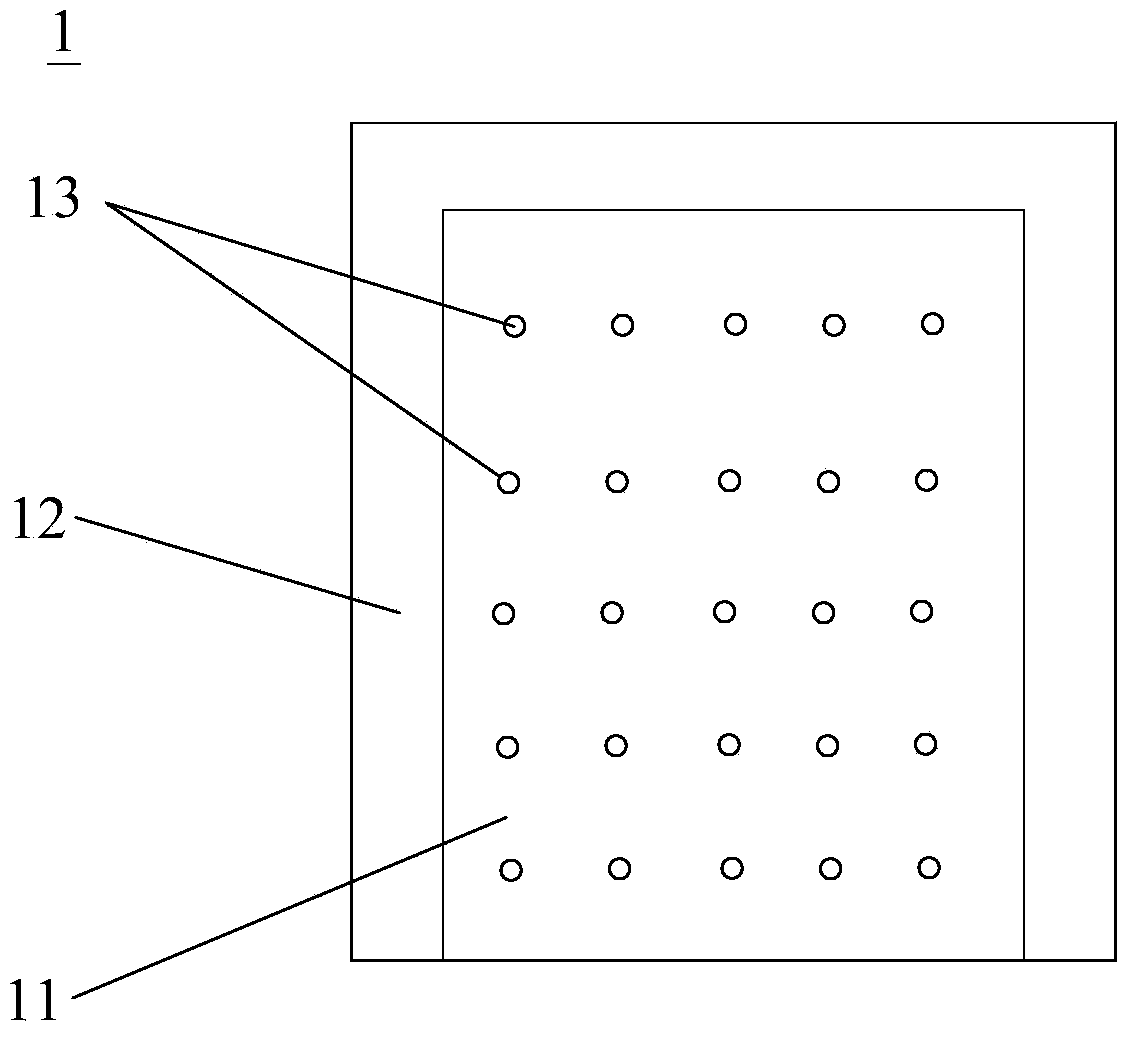

[0023] The production method is as follows: firstly, dissolve stearic acid and sodium hydroxide in the prescribed amount in edible alcohol at 60-70°C, add synergist, flavor and fragrance until completely dissolved, then add powder carrier and stir evenly to obtain edible Alcohol mixture, inject the mixture into the mold, cool to normal temperature, and solidify and form to obtain the solid alcohol preservative; then put the above solid alcohol preservative into such as figure 1 The shown perforated packaging bag 1 is then sealed, and then the sealed perforated packaging bag 1 is put into a vacuum bag, sealed and vacuumed to obtain the product, wherein the perforated packaging bag 1...

Embodiment 2

[0025] A solid alcohol antistaling agent, comprising 5 parts by weight of stearic acid, 1 part of sodium hydroxide, 2 parts of allyl isothiocyanate, 20 parts of powder carrier, 100 parts of edible alcohol and 2 parts of essence and fragrance; Wherein the powder carrier is silicon dioxide.

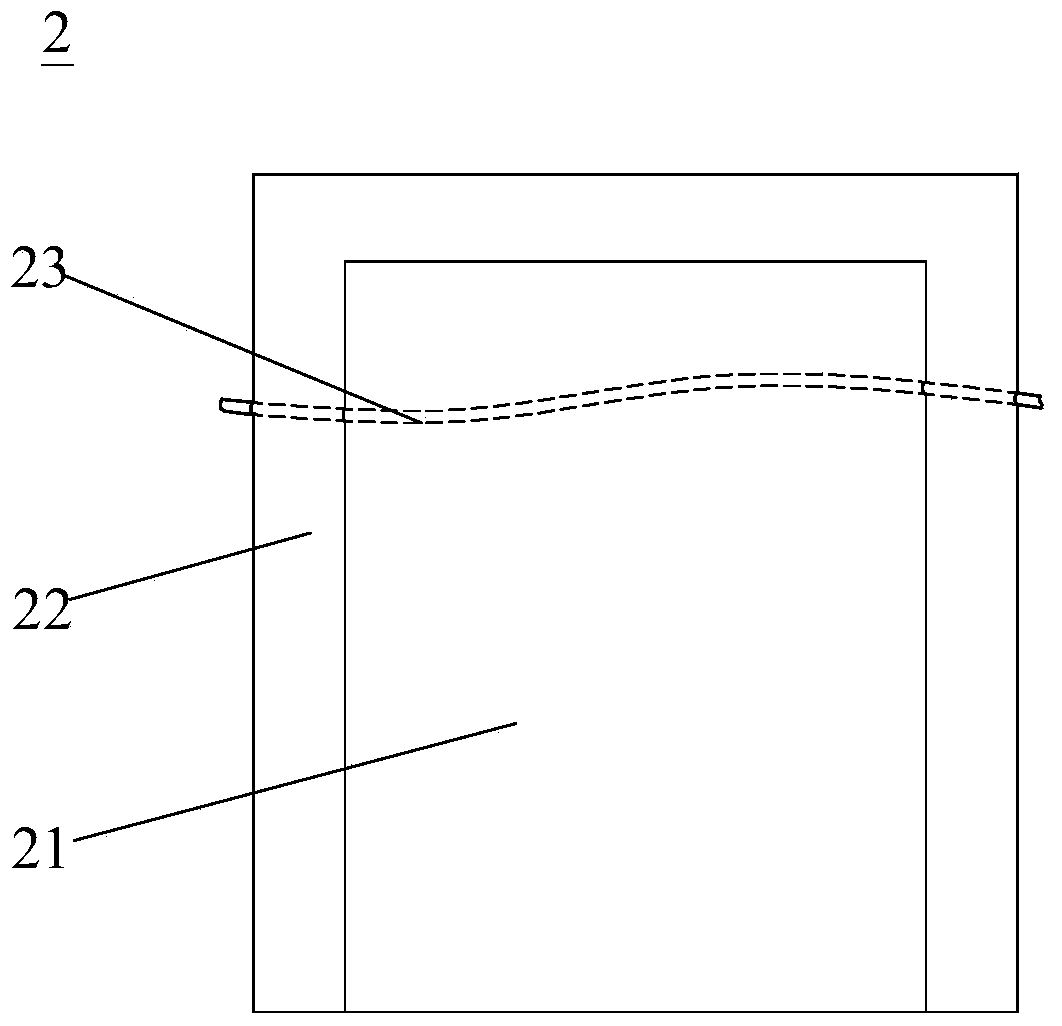

[0026] The production method is as follows: firstly, dissolve stearic acid and sodium hydroxide in the formula amount in edible alcohol at 60-70°C; Mixture, inject the above mixture into the mold, cool to normal temperature, and solidify and form to obtain the solid alcohol antistaling agent; then put the above solid alcohol antistaling agent into such as figure 2 The shown packaging bag 2 is then sealed, and then the sealed packaging bag 2 is put into a vacuum bag, sealed and vacuumed to obtain the product, wherein the packaging bag 2 is three-sided thermoplastic edge sealing, including a packaging part 21, an edge sealing part 22 and Volatile thread 23, the volatile thread 23 is drawn o...

Embodiment 3

[0028] A solid alcohol preservative, comprising 6 parts by weight of stearic acid, 1 part of sodium hydroxide, 0.5 part of allyl isothiocyanate, 70 parts of powder carrier, 100 parts of edible alcohol and 1 part of essence and fragrance; The powder carrier is a mixture of pregelatinized starch and diatomaceous earth.

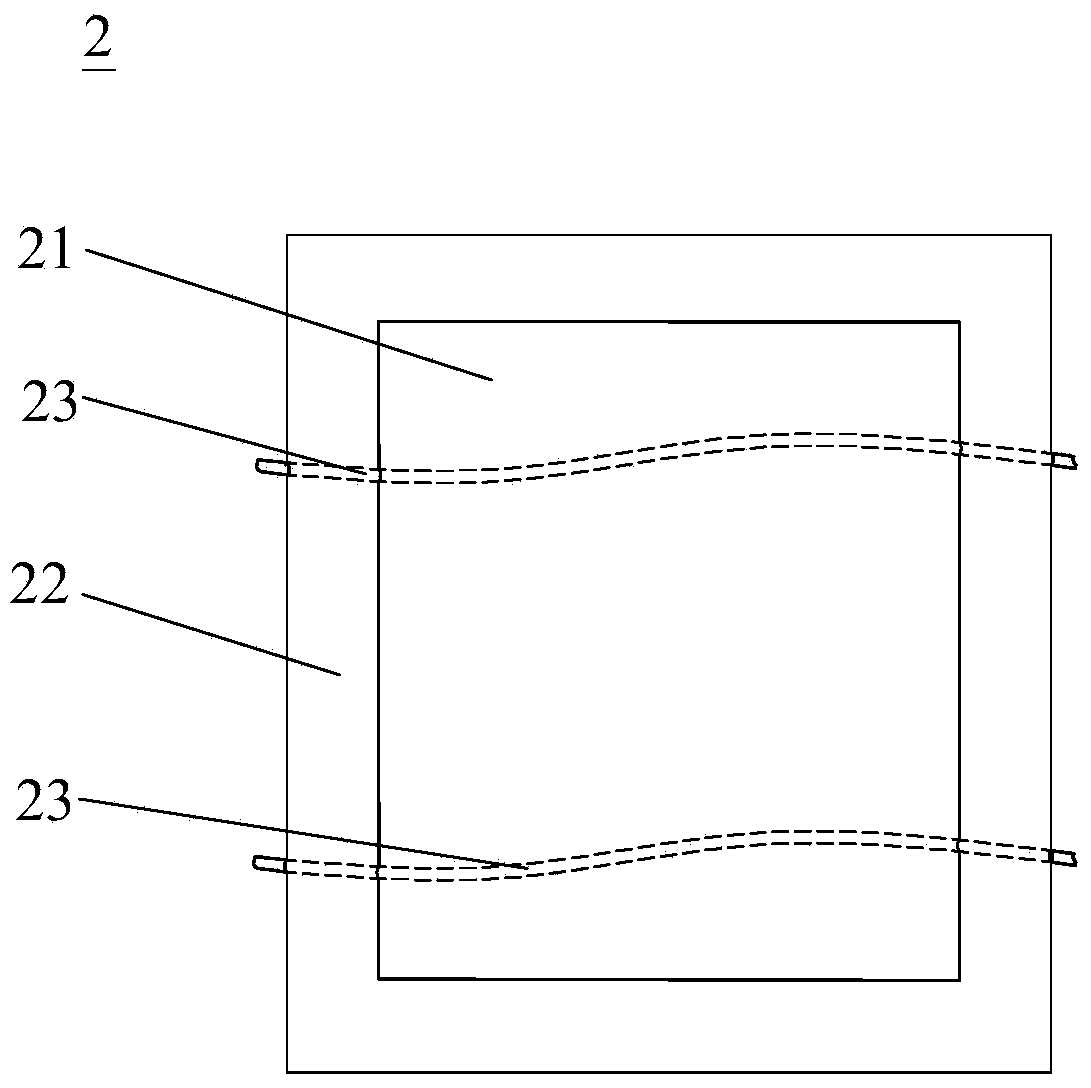

[0029] The production method is as follows: firstly, dissolve stearic acid and sodium hydroxide in the prescribed amount in edible alcohol at 60-70°C; The mixture is cooled to normal temperature to obtain a solidified product, and the above-mentioned certain amount of solidified product is pressed into tablets to form a tablet-type solid alcohol preservative; then the above solid alcohol preservative is packed into such as image 3The packaging bag 2 shown is sealed to obtain the product, wherein the packaging bag 2 includes a packaging part 21, an edge sealing part 22 and a volatilization line 23, and the volatilization line 23 is drawn out from the packaging p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com