Multilayered filtering equipment with backwashing device

A multi-layer filtration and functional technology, applied in the direction of loose filter material filter, filtration separation, gravity filter, etc., can solve the problems of poor filtering effect and complicated backwashing of filter material, so as to alleviate the impact, facilitate maintenance, Uniform discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

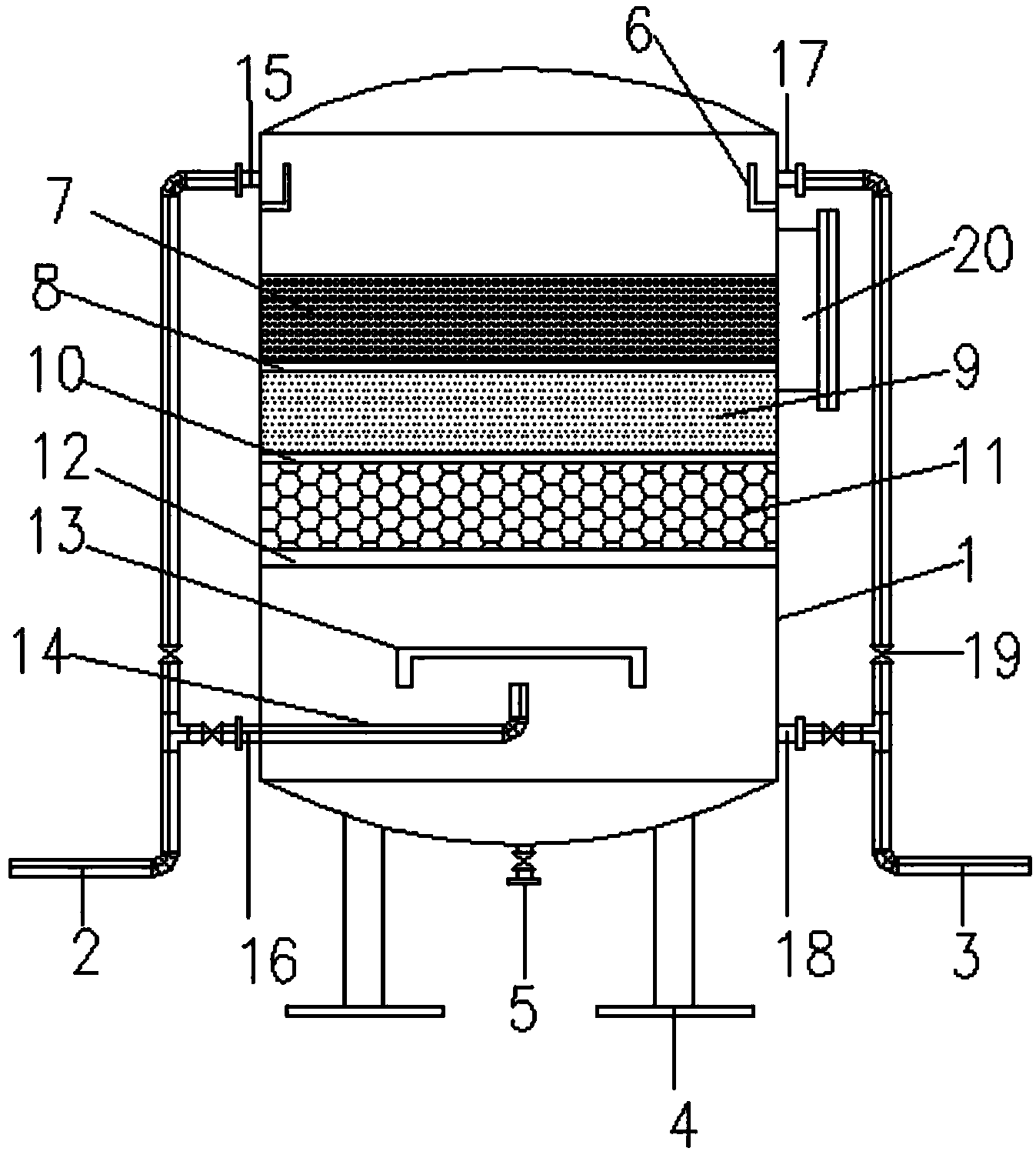

[0020] Combine below figure 1 The present invention is further described:

[0021] A multi-layer filter device with backwashing function, its external structure mainly includes a cylinder body 1, a feed pipe 2, a discharge pipe 3, a bracket 4, and a waste residue outlet 5. There are three filter material layers inside the cylinder body 1. From bottom to top, there are perlite layer 11, quartz sand layer 9, and activated carbon layer 7. The particle size of the filter material decreases step by step to increase the filtration efficiency. Layer 9 and perlite layer 11 are provided with a steel mesh layer II10, and the lower part of perlite layer 11 is provided with a filter material support layer 12, and the feed pipe 2 is divided into two branch pipes respectively connected to the upper feed port 15 and the lower feed port 16, and the discharge The pipe 3 is also divided into two branch pipes respectively connected to the upper discharge port 17 and the lower discharge port 18....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com