Wet dust removal and waste heat recovery device

A waste heat recovery device, wet dust removal technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve problems such as waste of raw materials and energy, air pollution, etc., achieve high energy utilization, reduce thermal pollution and other problems , the effect of reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

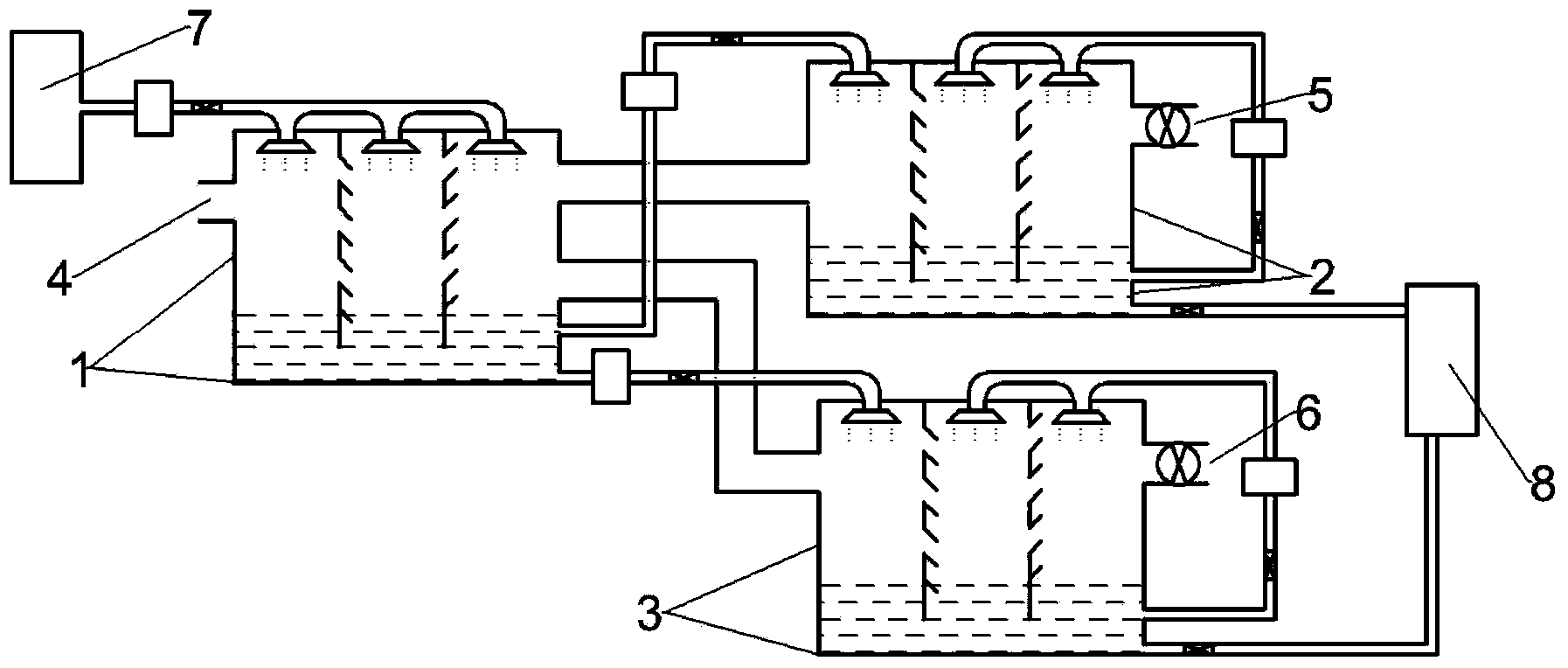

[0020] Such as figure 1 As shown, the invention provides a kind of plasma and water curtain dedusting device, comprising:

[0021] The first liquid storage tank 7 is used to hold molasses alcohol fermentation liquid;

[0022] The first dust removal chamber 1, the second dust removal chamber 2 and the third dust removal chamber 3; the inside of the first dust removal chamber 1, the second dust removal chamber 2 and the third dust removal chamber 3 are all vertically provided with two partitions, the Two partitions divide the first dust removal chamber 1, the second dust removal chamber 2 and the third dust removal chamber 3 into three spaces, the lower parts of the three spaces communicate with each other, and the upper parts of the three spaces are respectively provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com