Method and equipment for underwater welding of sacrificial anode based on friction stud welding

A friction stud welding, sacrificial anode technology, applied in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve the problems of moving to shore or under waterless conditions, and difficult underwater welding methods, and achieve good quality, Quick separation and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is based on the underwater welding method of the sacrificial anode of friction stud welding, adopts friction heat generation mode to weld the workpiece to be welded underwater, and adopts the mode of friction stud welding to directly sacrifice the underwater structure in the water environment The anode assembly is welded, and the method includes the following steps:

[0019] Step 1, positioning and installing the sacrificial anode assembly on the welding equipment on land or on the ship deck;

[0020] Step 2, using lifting equipment to lower and fix the anode assembly and welding equipment on the underwater structure to be welded;

[0021] Step 3, welding the anode assembly;

[0022] Step four, release the anode assembly and recover the welding equipment.

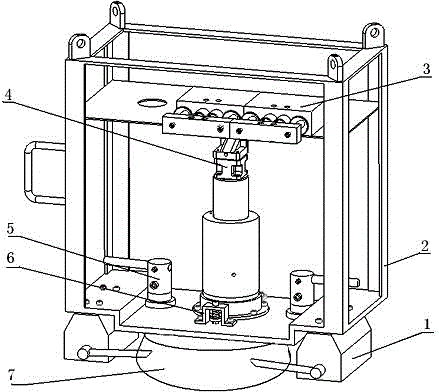

[0023] like figure 2 As shown, the sacrificial anode underwater welding equipment based on friction stud welding of the present invention mainly consists of a positioning locking magnet 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com