Novel belt-type conveyer driving roller

A belt conveyor, driving roller technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of complex lagging process, pollution of operators and environment, harsh working environment and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

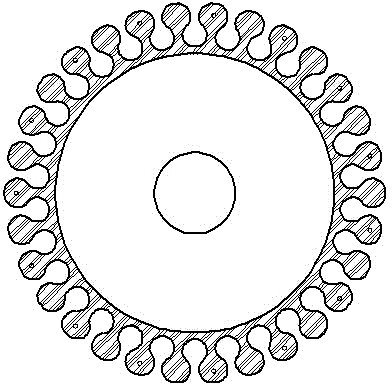

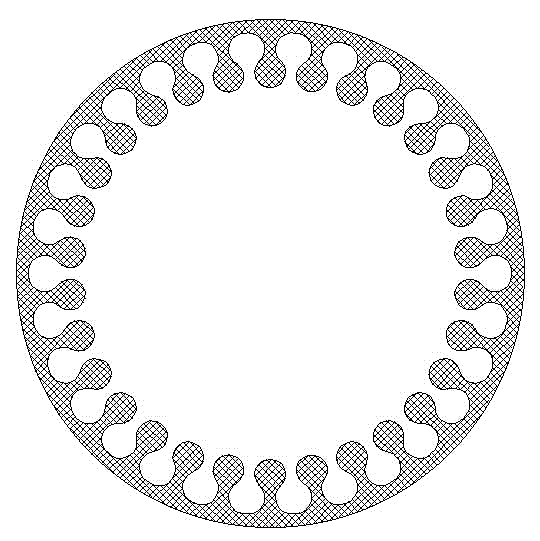

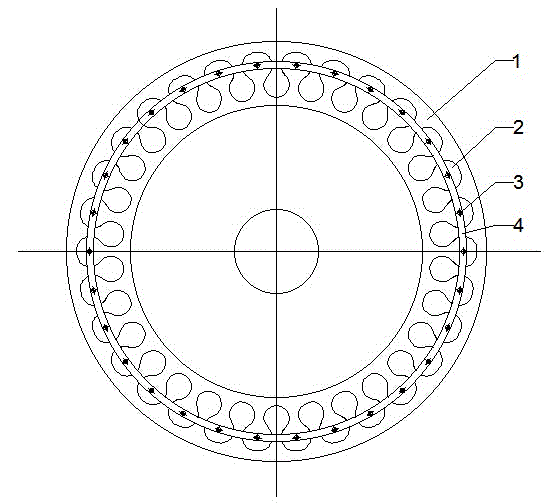

[0012] Forcefully insert the processed rubber lagging (1) into the drum along the groove on the wall of the cylinder (2) to ensure an interference fit between the convex part of the rubber lagging (1) and the concave part of the cylinder. Then fix the two retaining rings (4) on the end face of the barrel with countersunk screws (3). Finally, assemble the roller shaft (6), bearing (5) and other components in sequence. When repairing the lagging (1), there is no need to remove the roller, and the excessively worn part of the groove on the lagging (1) is directly removed, and then repaired by the cold-bonding lagging process.

[0013] The working principle of the new belt conveyor drive roller is as follows:

[0014] The lagging is firmly fixed on the drum body by relying on the mutual engagement of the special rotary surface of the round gourd structure between the drum body and the rubber lagging. This kind of engagement is an interference fit, and the contact area between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com