A kind of method of synthesizing bismuth oxychloride pearlescent pigment

A pearlescent pigment, bismuth oxychloride technology, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of difficult wastewater treatment, high reaction temperature, high energy consumption, etc., to avoid surfactants and impurity ions The effect of introduction, good gloss and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

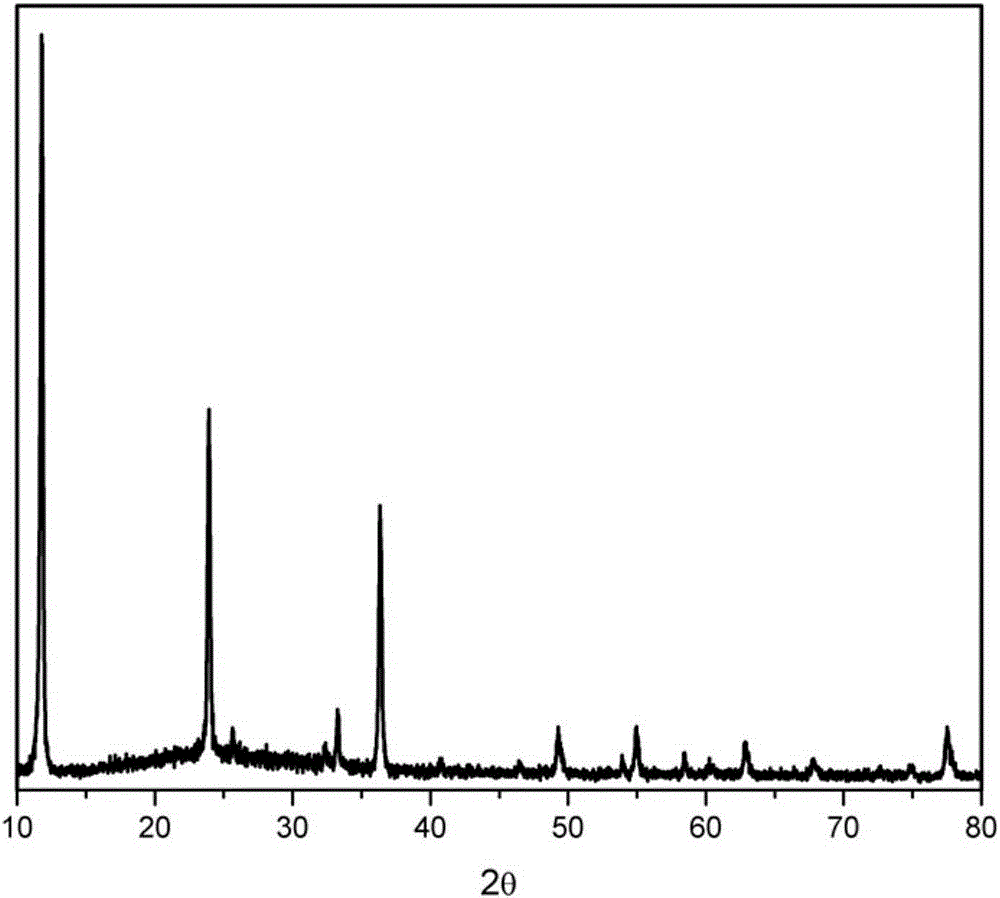

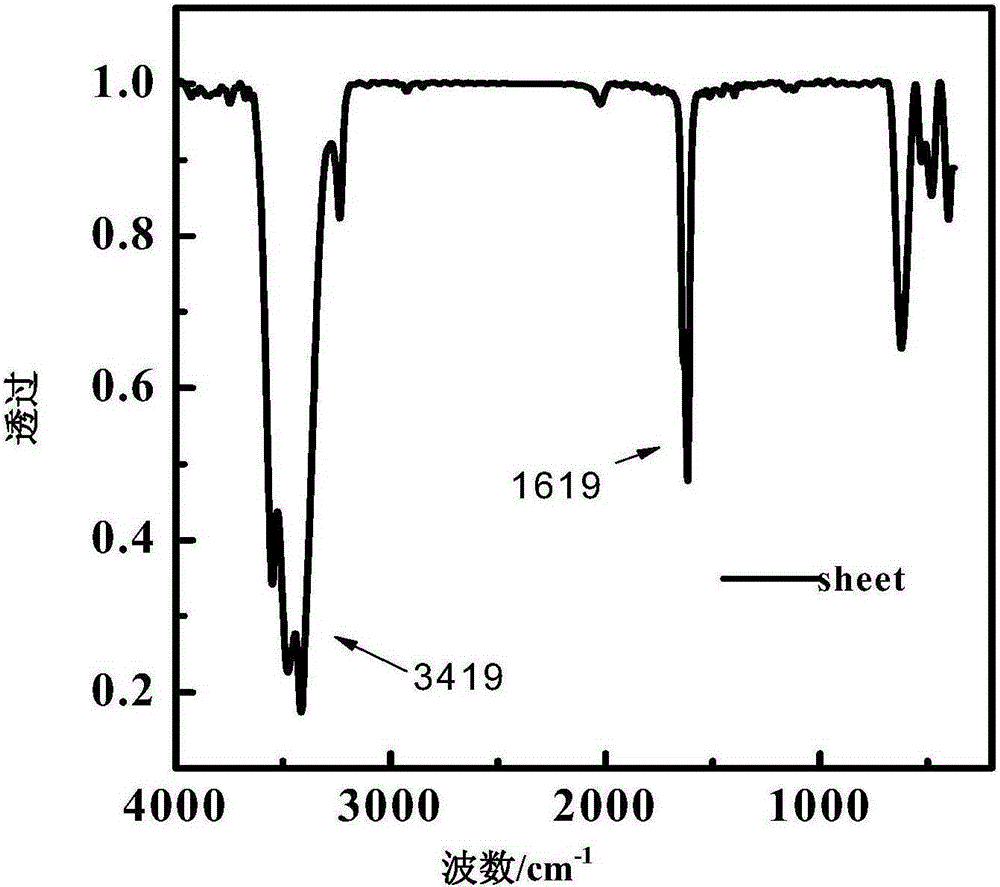

Embodiment 1

[0028] Weigh 0.631g (2mmol) BiCl 3 Dissolve in 50mL hydrochloric acid with a concentration of 1mol / L to make solution A; weigh 25mmol NaOH and dissolve it in 50mL deionized water to make solution B; add 50mL deionized water to a 250mL three-necked flask, and adjust the pH with concentrated hydrochloric acid to 1, and the temperature was raised to 70°C; under magnetic stirring, simultaneously add solution A and solution B into the three-necked flask, wherein, the addition rate of solution A was 1 mL / min, and the addition rate of solution B was 200 μL / min, after solution A was added After completion, continue to add solution B at a constant rate until the reaction is completed; filter the reaction mixture, wash with deionized water, and dry at room temperature to obtain the finished product of flake bismuth oxychloride pearlescent pigment. The product yield is 96%, and the purity is 99.9%.

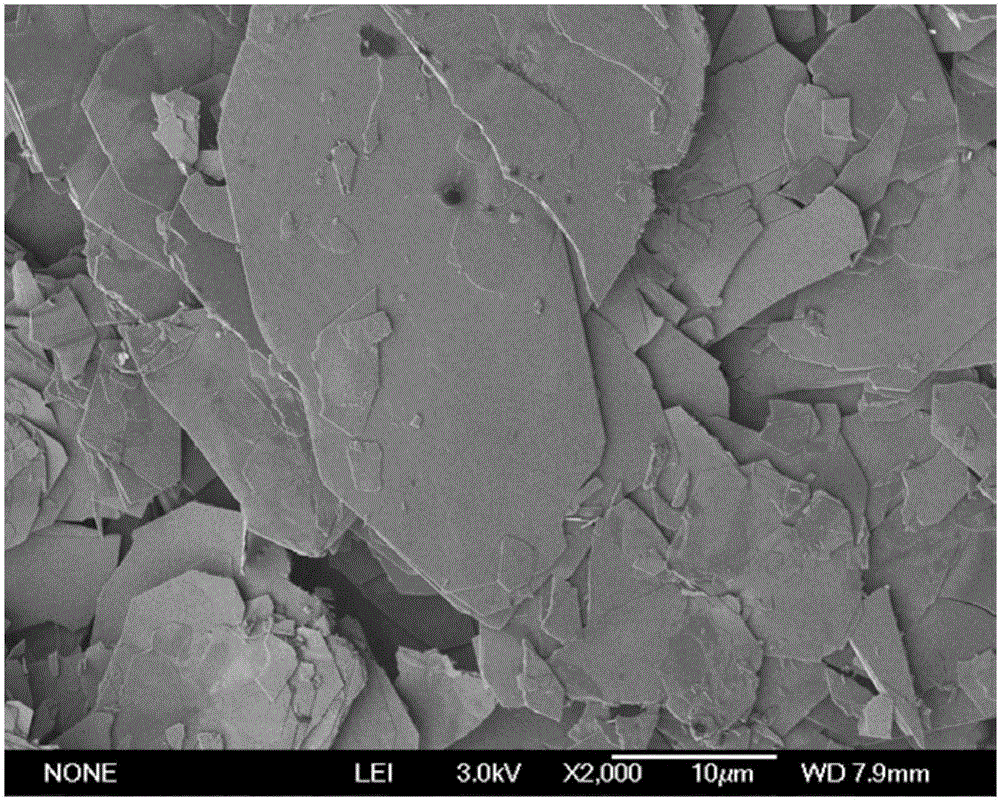

[0029] figure 2 The scanning electron micrograph of finished product is made for this...

Embodiment 2

[0031] Weigh 0.946g (3mmol) BiCl 3 Dissolve in 50mL hydrochloric acid with a concentration of 1mol / L to make solution A; weigh 25mmol NaOH and dissolve it in 50mL deionized water to make solution B; add 50mL deionized water to a 250mL three-necked flask, and adjust the pH with concentrated hydrochloric acid to 1, and heat up to 70°C; under magnetic stirring, add solution A and solution B at the same time, wherein, solution A is added at a rate of 1mL / min, and solution B is added at a rate of 200μL / min. After solution A is added, continue at a constant rate Add solution B until the reaction is complete; filter the reaction mixture, wash with deionized water, and dry at room temperature to obtain the finished product of flaky bismuth oxychloride pearlescent pigment. The product yield is 96%, and the purity is 99.9%.

Embodiment 3

[0033] Weigh 1.261g (4mmol) BiCl 3 Dissolve in 50mL hydrochloric acid with a concentration of 1mol / L to make solution A; weigh 25mmol NaOH and dissolve it in 50mL deionized water to make solution B; add 50mL deionized water to a 250mL three-necked flask, and adjust the pH with concentrated hydrochloric acid to 1, and heat up to 70°C; under magnetic stirring, add solution A and solution B at the same time, wherein, solution A is added at a rate of 1mL / min, and solution B is added at a rate of 200μL / min. After solution A is added, continue at a constant rate Add solution B until the reaction is complete; filter the reaction mixture, wash with deionized water, and dry at room temperature to obtain the finished product of flaky bismuth oxychloride pearlescent pigment. The product yield is 95%, and the purity is 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com