Combined device for oily sewage treatment

A combined device and oil-sewage technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Low cost, reduced sewage production, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

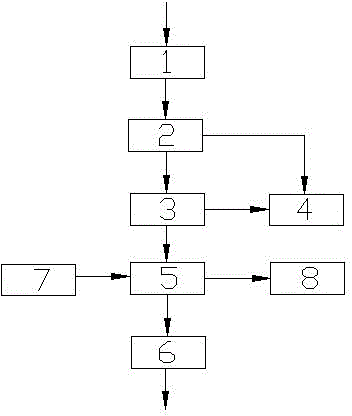

[0015] Example: As shown in the figure, the process of the oily sewage combined treatment device is as follows: oilfield sewage, as shown by the arrow, enters the grille 1, removes the larger debris in the sewage, prevents the pipeline from clogging, and protects the normal operation of the subsequent sewage treatment equipment; After the grid 1 is treated, the sewage enters the regulating oil separation tank 2, and the regulating oil separation pool 2 includes a plurality of oil separation pools in series, preferably two, the incoming water first enters the first oil separation pool, and uses the gravity separation method for oil separation After treatment, the floating oil enters the oil collecting tank 4 through the oil collecting tank. As the liquid level continues to rise, the oily sewage overflows to the second oil collecting tank for further separation, and the floating oil enters the oil collecting tank 4; Oil pool 3, the advection oil separator 3 includes a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com