Liquid silicone rubber and preparation method thereof

A liquid silicone rubber and inhibitor technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor adhesion, unreasonable formula ratio, and inability to meet the needs of use. The effect of good connection and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of liquid silicone rubber of the present invention is made up of following components by weight:

[0035]

[0036] The preparation method comprises the following steps:

[0037] Using a quantitative feeding device, add α, ω-divinylpolysiloxane, α, ω-dihydroxypolydimethylsiloxane, catalyst, and filler to the reaction device and heat-treat at 80°C for 0.5 hours, Add tetramethyldivinyldisiloxane, crosslinking agent, and inhibitor to solidify for 0.1 hour, cool with a cooling device, filter through a filter device, and then fill and store with an automatic filling device.

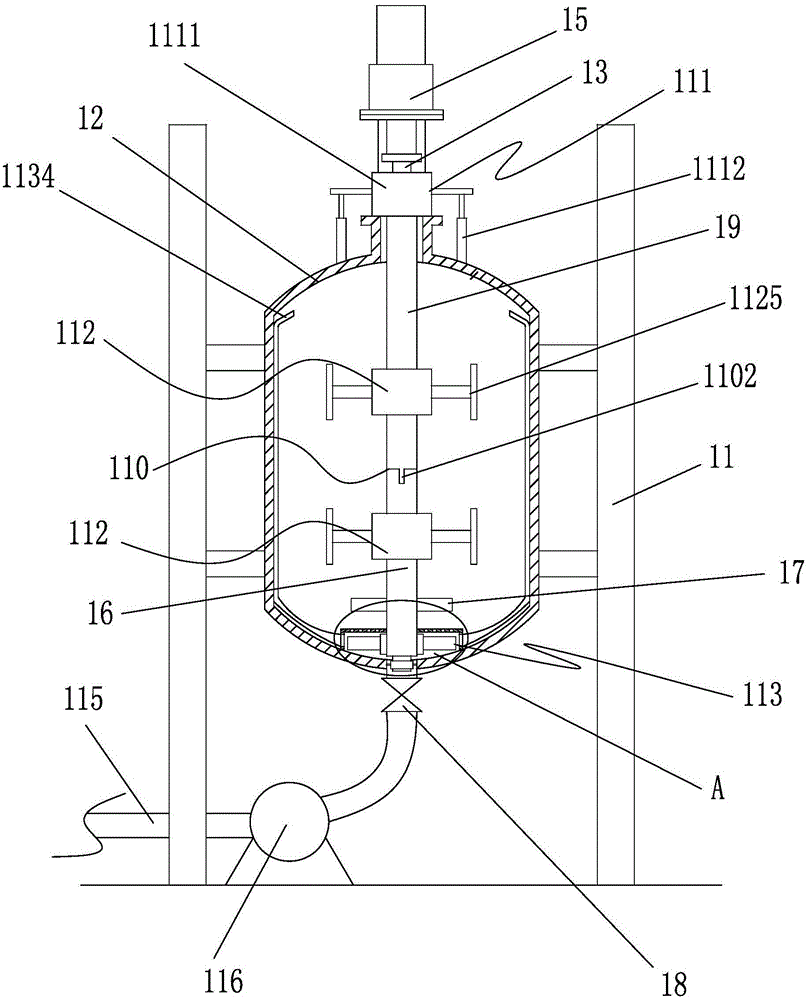

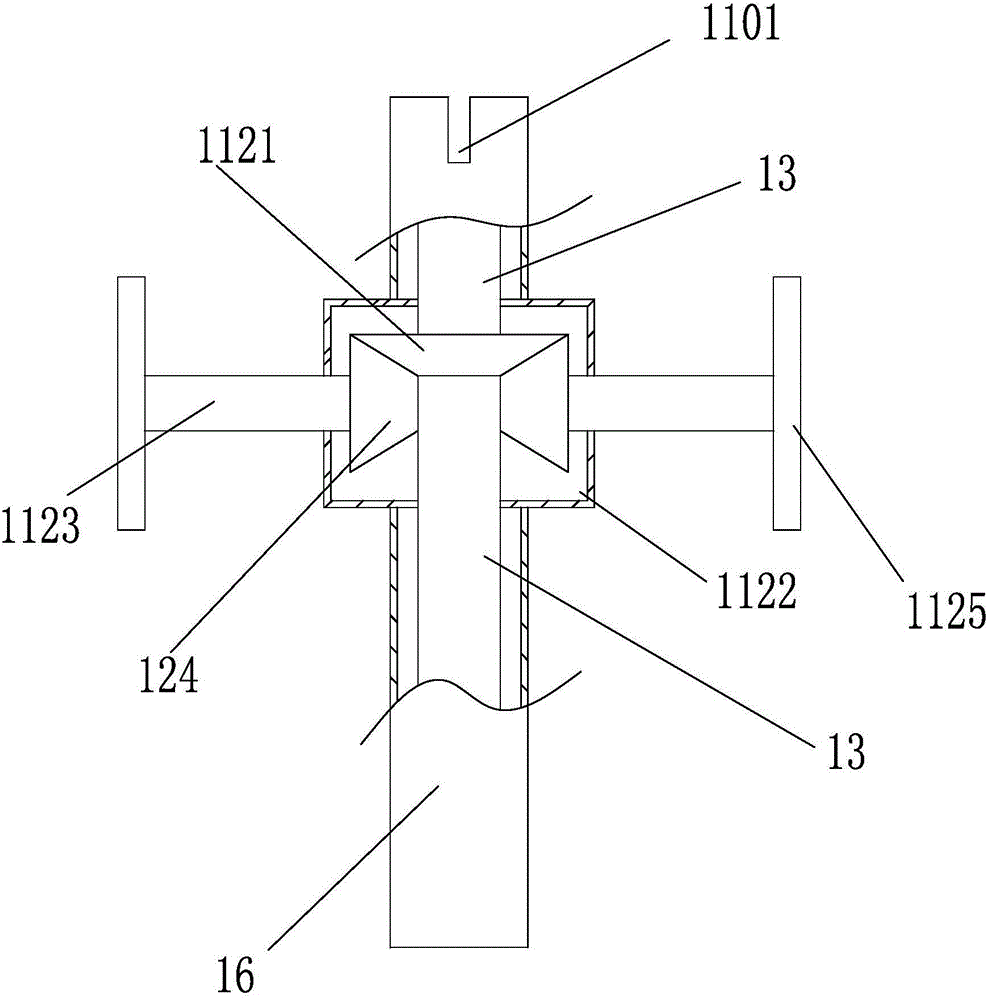

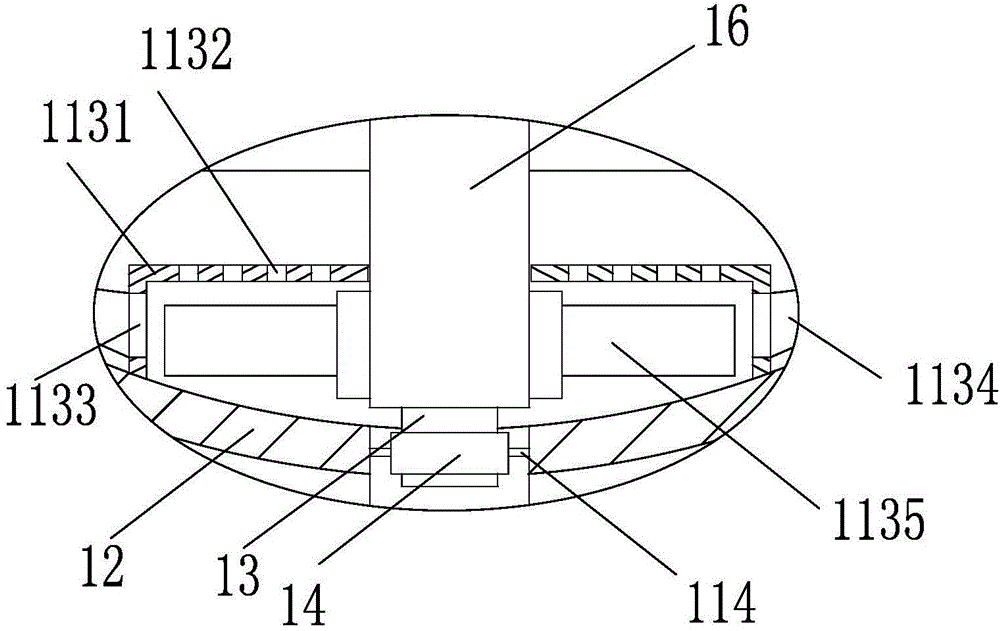

[0038] The reaction device 1 described in the present invention includes a support 11, a reaction kettle 12 is fixedly connected to the support 11, a stirring shaft 13 is arranged in the reaction kettle 12, and one end of the stirring shaft 13 passes through a bearing 14 Connected to the bottom of the reactor 12, the other end of the stirring shaft 13 extends out of the reactor 12 and is conne...

Embodiment 2

[0054] A kind of liquid silicone rubber of the present invention is made up of following components by weight:

[0055]

[0056] The preparation method comprises the following steps:

[0057] Using a quantitative feeding device, add α, ω-divinylpolysiloxane, α, ω-dihydroxypolydimethylsiloxane, catalyst, and filler to the reaction device and heat-treat at 90°C for 3 hours. Add tetramethyldivinyldisiloxane, crosslinking agent, and inhibitor to solidify for 5 hours, cool with a cooling device, filter through a filter device, and then fill and store with an automatic filling device.

[0058] The quantitative feeding device, reaction device, cooling device, filtering device and automatic filling device described in this embodiment are as described in embodiment 1.

Embodiment 3

[0060] A kind of liquid silicone rubber of the present invention is made up of following components by weight:

[0061]

[0062] Described inhibitor is 1-ethynyl-1-cyclohexanol, 2-methyl-3-butyn-alcohol and 3,5-dimethyl-1-hexyn-3-alcohol and 3-methyl-1 - Mixtures of dodecyn-3-ols. The filler is a mixture of quartz powder, diatomaceous earth, calcium carbonate, mica, aluminum oxide, calcium hydroxide and carbon black; the crosslinking agent is an organopolysiloxane containing at least two Si-H bonds alkyl.

[0063] The preparation method comprises the following steps:

[0064] Using a quantitative feeding device, add α, ω-divinyl polysiloxane, α, ω-dihydroxypolydimethylsiloxane, catalyst, and filler to the reaction device and heat treat at 80-90 ° C for 0.5- After 3 hours, add tetramethyldivinyldisiloxane, crosslinking agent, and inhibitor to solidify for 0.1-5 hours. After cooling with a cooling device, filter through a filter device, and then use an automatic filling de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com