Device for collecting zinc smoke of hot-dip galvanizing workshop

A collection device and hot-dip galvanizing technology are applied in hot-dip galvanizing process, dust removal, coating, etc., which can solve the problems of deformation and damage of movable parts of the cover body, inconvenient galvanizing operation, and cumbersome process flow, etc. Easy maintenance, reduced zinc consumption, and good working vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

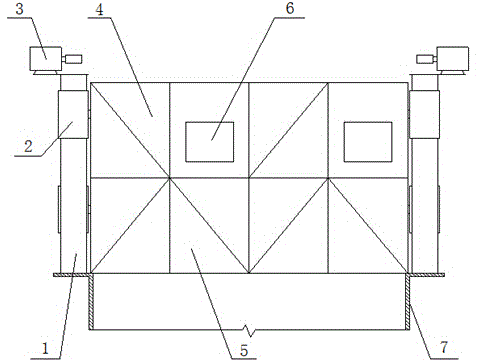

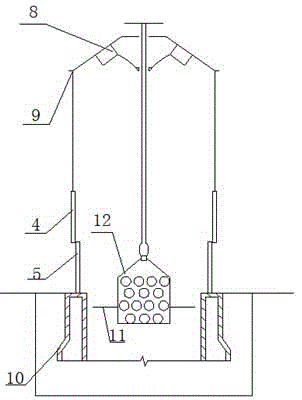

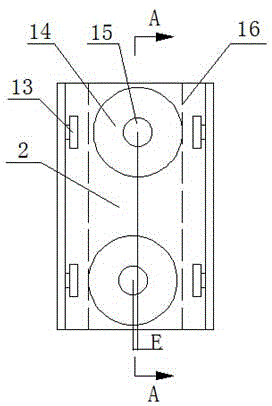

[0021] In the figure, 1-vertical frame; 2-wheel frame; 3-reduction motor; 4-outer movable baffle; 5-inner movable baffle; 6-observation window; Entrance; 9-dust removal cover; 10-longitudinal groove wall of zinc pot; 11-zinc bath; 12-workpiece; 13-small wheel; 14-big wheel. 15-major shaft; 16-big wheel guide groove wall; 17-small shaft; 18-small wheel guide groove wall; E-big wheel eccentricity; e-small wheel eccentricity.

[0022] figure 1 As shown, the wheel frame 2 and the stand 1 move linearly through the sliding contact of each groove surface, and the bumps welded on the wheel frame 2 are connected with the bar-shaped holes on the movable baffles 4 and 5 . When the workpiece is galvanized, the motor 3 starts to drive the external baffles on both sides to rise to a limited position, and the internal baffles on both sides do not move, so that a closed space is formed above the zinc pot; the operator can pass through the observation window 6 Observe the galvanizing work. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com