Indicator diagram performance analysis-based pumping unit intelligent equipment and calculation method thereof

A technology of intelligent equipment and pumping unit, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve problems such as shortened life of oil production components, insufficient liquid supply, damage to motors and pumping unit equipment, and achieve The effects of protecting oil pumping equipment and safe production, realizing digital management, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

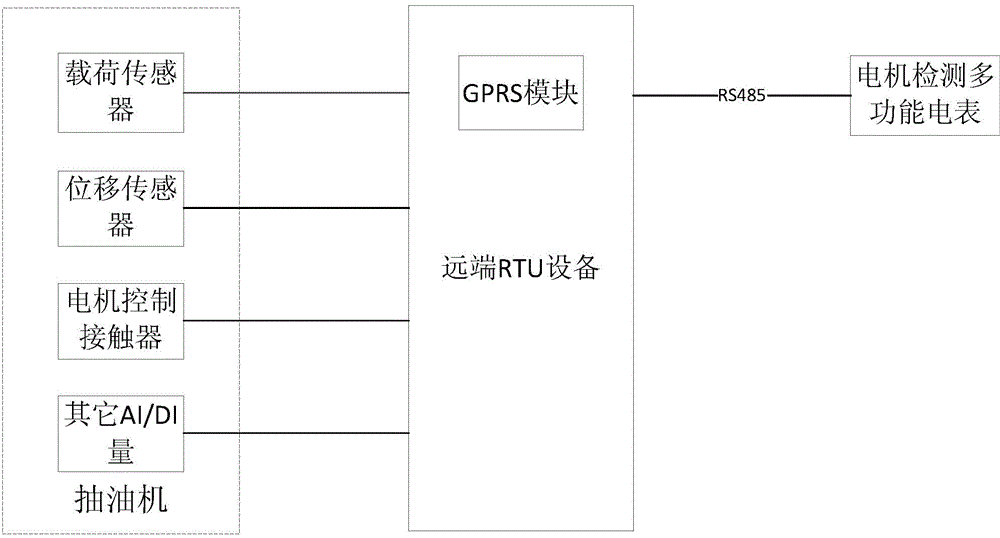

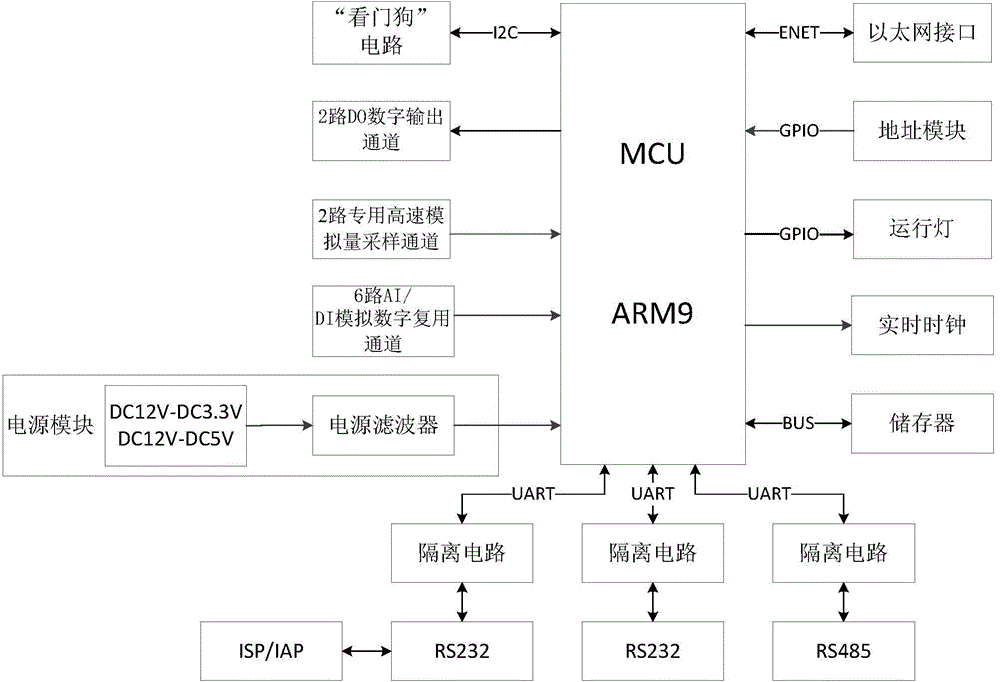

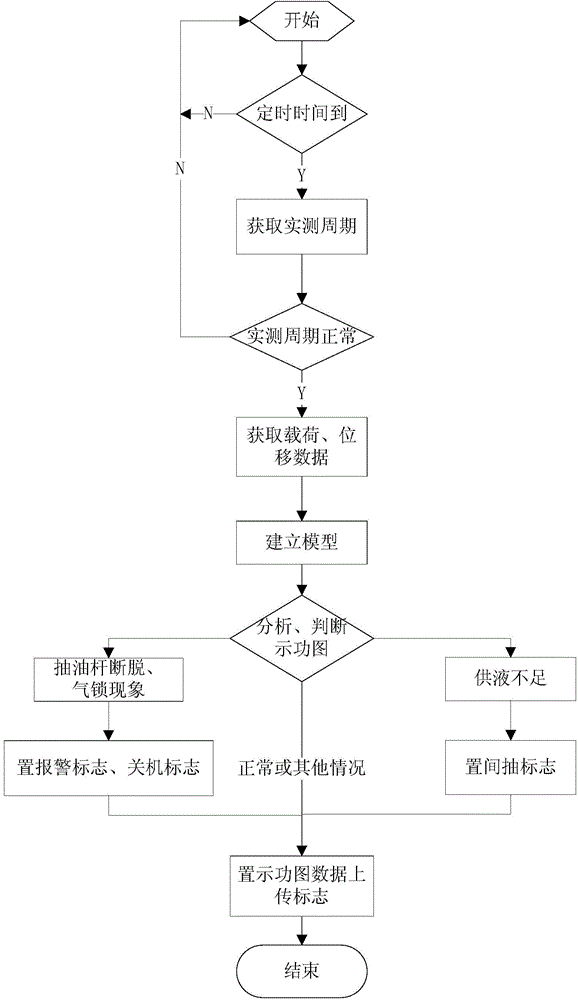

[0037] see figure 1 with figure 2 , the present invention is based on the dynamometer diagram working condition analysis of the pumping unit intelligent equipment, including the pumping unit and remote RTU equipment, the pumping unit includes a motor control contactor, a load sensor and a displacement sensor, and the remote RTU equipment includes an ARM9 processor And the power module connected to it, the power module includes a power filter connected to the ARM9 processor, and a power supply connected to the power filter, the power supply includes DC12V-DC3.3V and DC12V-DC5V, 2 dedicated high-speed channels on the ARM9 processor The analog sampling channel collects the information of the load sensor and displacement sensor of the pumping unit. The ARM9 processor controls the motor control contactor of the pumping unit through 2 DO digital output channels. The ARM9 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com