Differential pressure flow meter-type smart adjustable throwing and fishing injection dispenser

A flowmeter and injector technology, which is applied in the direction of measurement, production fluid, wellbore/well components, etc., can solve the problems of inability to achieve accurate injection, eccentric injectors cannot realize continuous adjustment of injection volume, poor sealing, etc., to improve High labor efficiency, good sealing, and the effect of solving blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

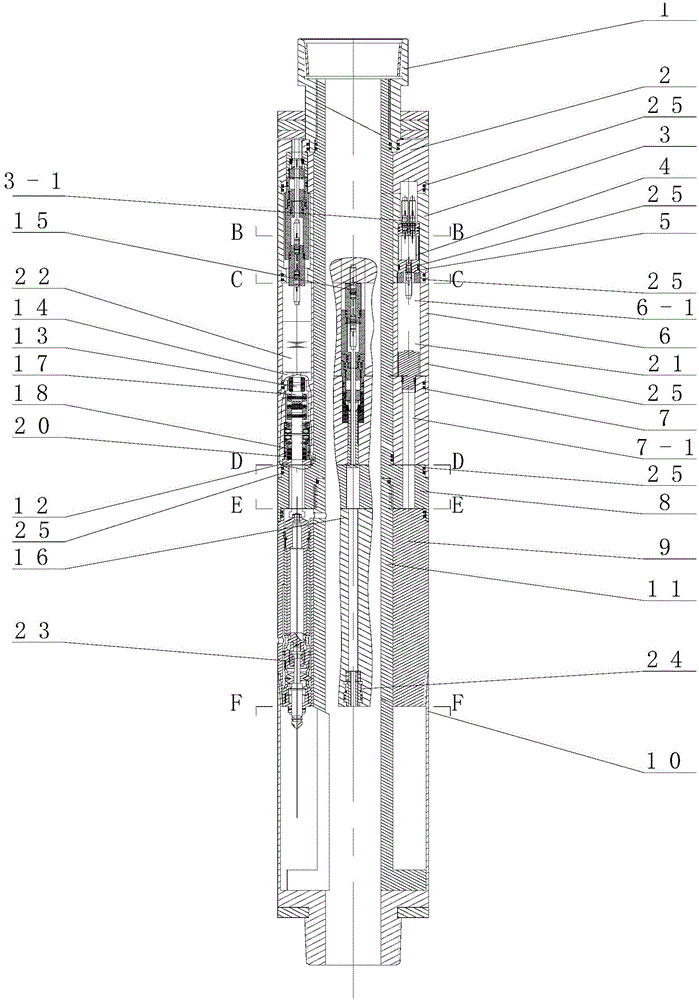

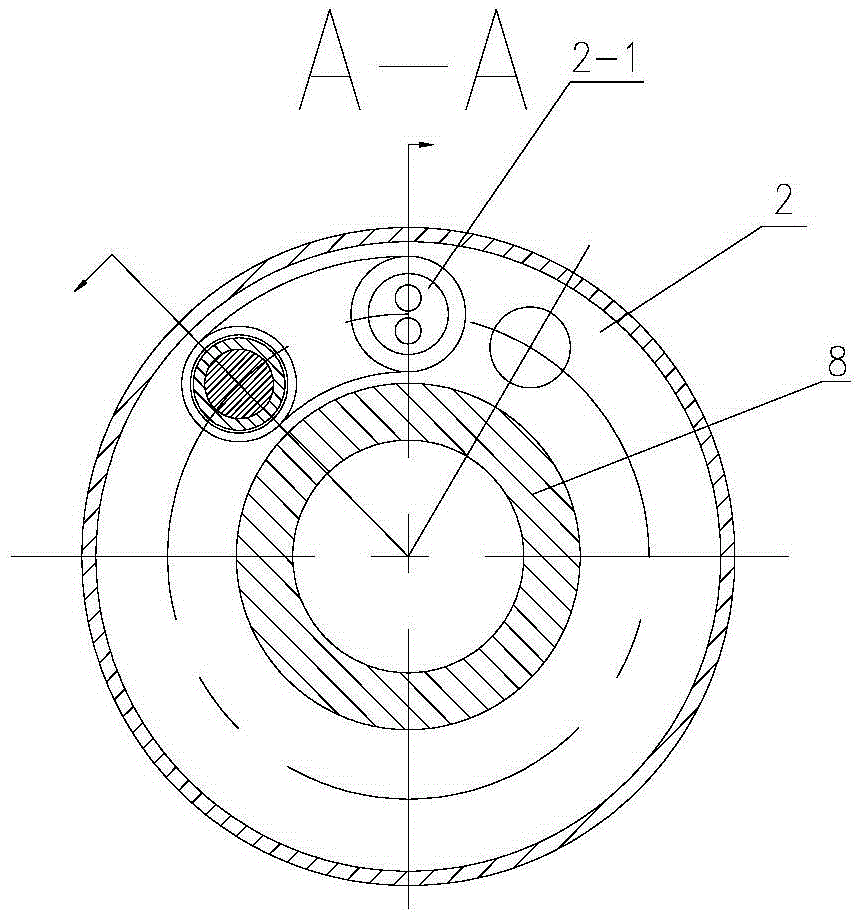

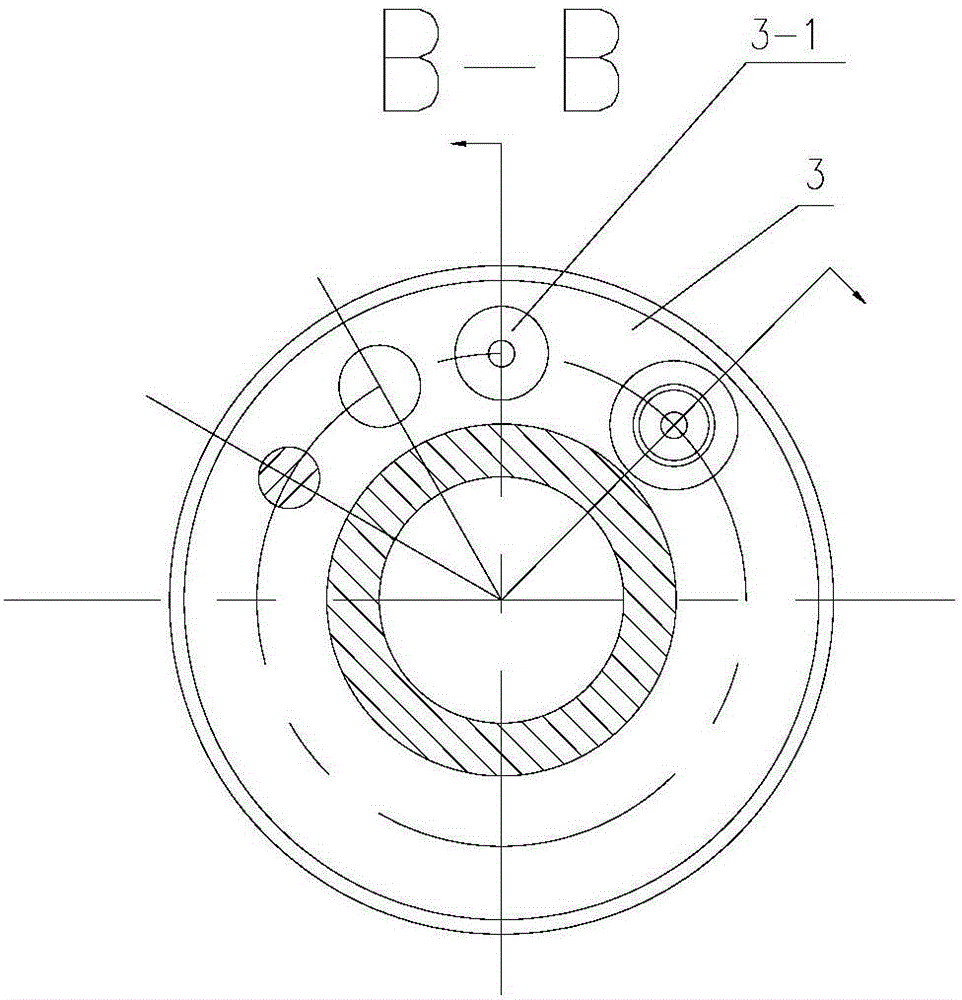

[0008] Specific implementation mode one: combine Figure 1 to Figure 11 To illustrate this embodiment, the differential pressure flowmeter type intelligent adjustable throwing and dispensing device in this embodiment includes an upper connector body 1, an upper cable body 2, a pin body 3, a pin bridge piece 4, and a pin lock nut 5 , motor housing 6, bearing housing 7, connecting body 8, upper outer housing 9, lower joint body 10, central pipe body 11, bearing set jacking wire 12, rigid coupling 13, anti-rotation body 14, middle cable Joint assembly 15, upper cable joint assembly 16, shaft connecting rod 17, car seal installation frame 18, bearing assembly 19, car seal 20, pressure sensor 21, motor 22, plug 23 and cable joint body 24, connecting body 8. The central pipe body 11 is arranged in order from top to bottom. The upper end of the central pipe body 11 is inserted into the lower end of the connecting body 8. The upper cable body 2, the pin body 3, the motor housing 6 and...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the differential pressure flowmeter type intelligent adjustable casting and fishing injection device of this embodiment also includes a plurality of sealing rings 25, and an outer wall at the lower end of the upper joint body 1 and an outer wall at the upper end of the upper cable body 2 are provided. There are two sealing rings 25, two sealing rings 25 are arranged between the outer side wall of the pin bridge 4 and the inner side wall of the first annular cavity 3-1, the outer side wall of the lower end of the pin body 3 and the motor housing Two sealing rings 25 are arranged between the outer side walls of the upper end of the 6, two sealing rings 25 are arranged between the inner side walls of the lower end of the motor housing 6 and the outer side walls of the upper end of the bearing housing 7, and the inner side of the lower end of the bearing housing 7 Two sealing rings 25 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com