Microbeam X-ray spectral fluorometer

A fluorescence spectrometer and X-ray technology, applied in the field of X-ray fluorescence analysis spectrometer, can solve the problems of resolution and analysis data error, the intensity of the irradiated sample point becomes smaller, etc., to solve the analysis error and improve the resolution effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

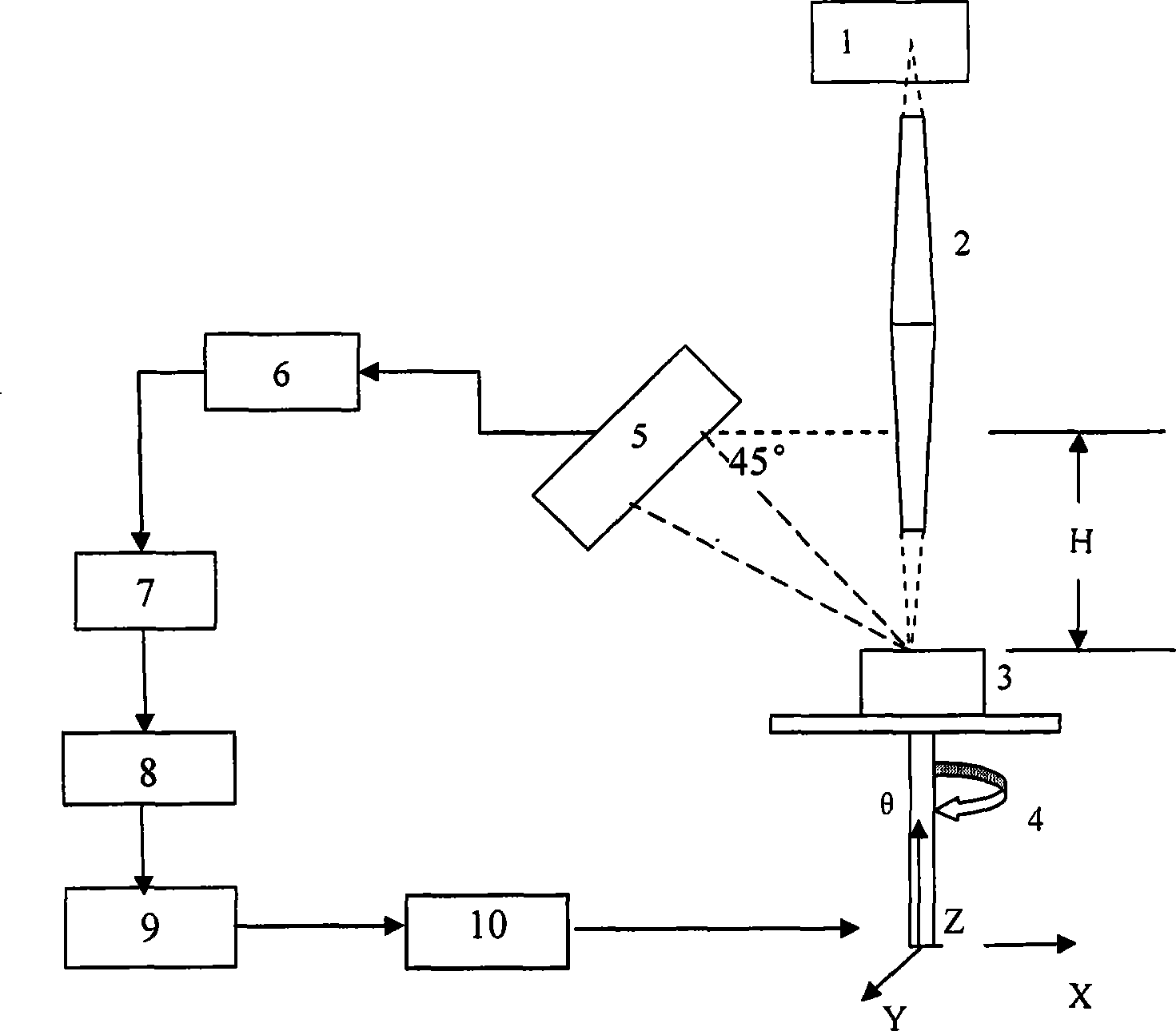

[0020] See attached figure 1 , the present invention provides a micro-beam X-ray fluorescence spectrometer, comprising: Oxford 50 micron, 50-watt micro-focus spot X-ray tube 1, capillary X-ray converging lens 2, sample stage 4, laser with high-precision resolution less than 5 microns Displacement sensor 5, digital-to-analog conversion card 6, computer 7;

[0021] The X-ray tube 1 is located above the sample stage 4, and X-rays pass through the capillary X-ray converging lens 2 and irradiate the sample on the sample stage 4. The sample 3 and the capillary X-ray converging lens 2 The distance between is equal to the back focal length of the capillary X-ray converging lens 2;

[0022] The displacement sensor 5 is located obliquely above the sample 3, and forms an angle of 45° with the horizontal plane, and its detection point is the same point as the tested point; the displacement sensor 5 is electrically connected with the computer 7 for detecting The vertical distance H betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com