Waste gas purification real-time monitoring system and method

A real-time monitoring system and exhaust gas purification technology, applied in transmission systems, signal transmission systems, general control systems, etc., can solve problems such as the inability to monitor and manage effectively in real time, and achieve the effect of automatic real-time monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

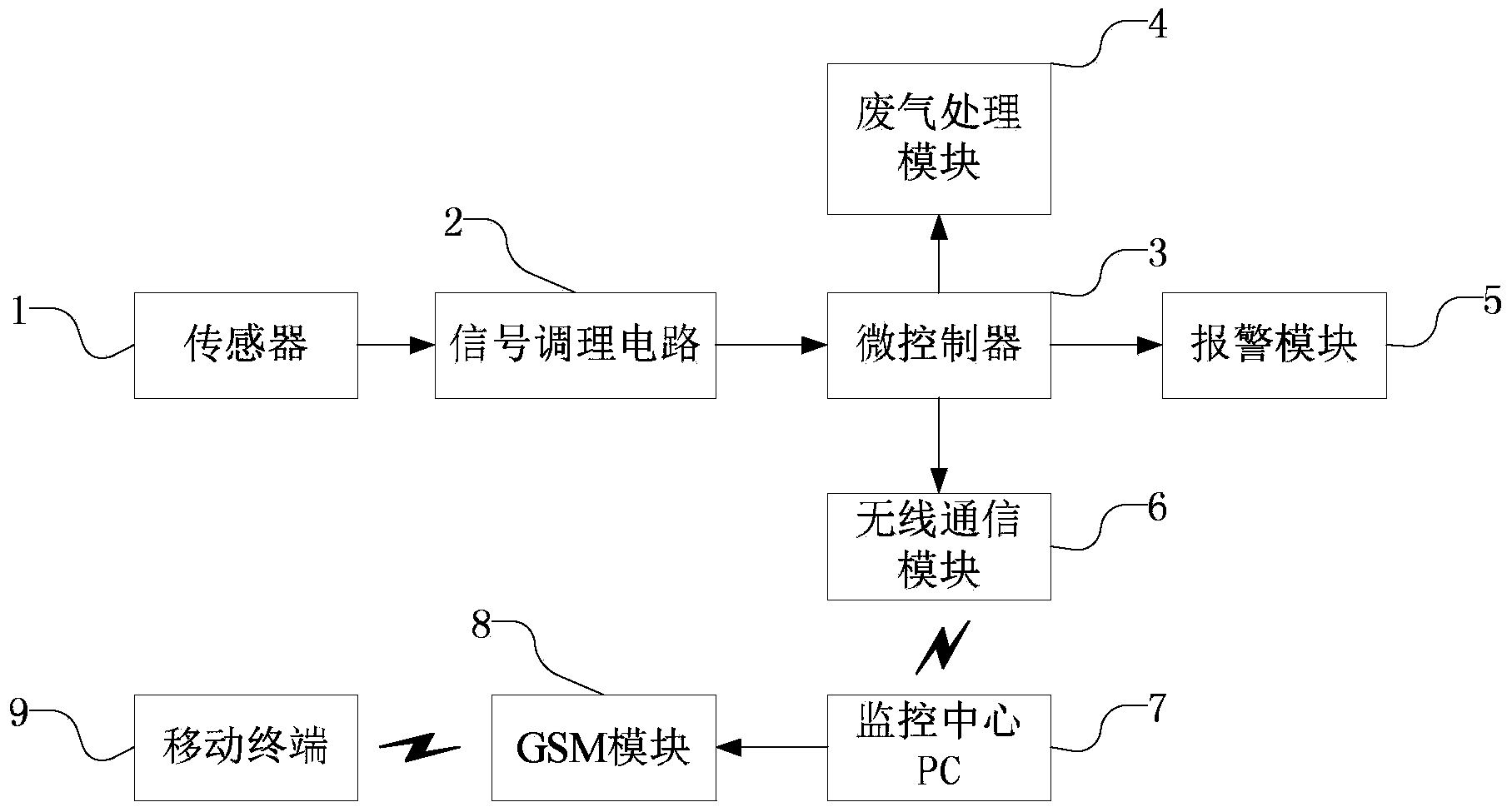

[0033] System embodiment 1: Such as figure 1 As shown, it includes a sensor 1, a signal conditioning circuit 2, a microcontroller 3, an exhaust gas treatment module 4, an alarm module 5, a wireless communication module 6, a monitoring center PC7 and a mobile terminal 9; the sensor 1 is connected to the signal conditioning circuit 2, The signal conditioning circuit 2, exhaust gas treatment module 4, alarm module 5 and wireless communication module 6 are all connected to the microcontroller 3; the microcontroller 3 is wirelessly connected to the monitoring center PC7 through the wireless communication module 6; the monitoring center The PC7 is connected with a GSM module 8, and the monitoring center PC7 is wirelessly connected with the mobile terminal 9 through the GSM module 8.

[0034] The sensor 1 is used to collect data information of exhaust gas to be discharged in real time. The data information includes required information such as the concentration and duration of the...

Embodiment 2

[0048] System embodiment 2: The structure is basically the same as that of system embodiment 1, and the similarities will not be described again, but the difference is:

[0049] The sensor 1 includes 3 groups of sensors, each group of sensors includes 2 galvanic cell type oxidation sensors for detecting oxygen and 2 infrared sensors for detecting hydrocarbons.

[0050] The wireless communication module 6 is a wireless WiFi module. Of course, the wireless communication module may also be other wireless communication devices capable of wireless data transmission.

[0051] The alarm module 5 only includes a voice alarm device.

[0052] The GSM module 8 is integrated on the main board of the monitoring center PC, and is connected with the monitoring center PC7 by wire.

Embodiment 3

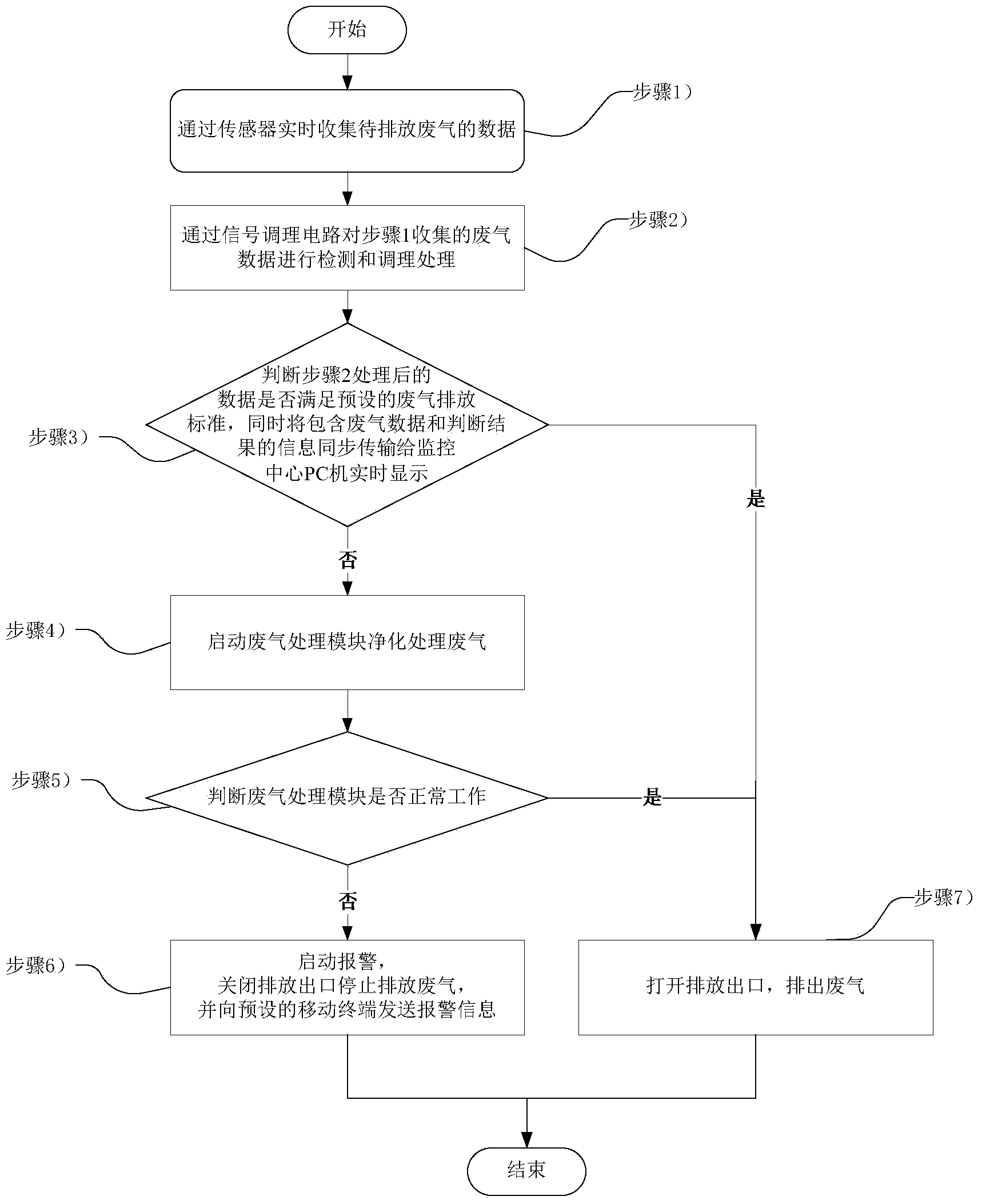

[0054] Such as figure 2 As shown, the exhaust gas purification real-time monitoring method used in the exhaust gas purification real-time monitoring system in the present invention provided by Embodiment 3 of this method includes the following steps:

[0055] Step 1, collect the data of the exhaust gas to be discharged in real time through the sensor;

[0056] Step 2, detecting and conditioning the exhaust gas data collected in step 1 through the signal conditioning circuit;

[0057] Step 3: Judging whether the data processed in step 2 meets the preset exhaust gas emission standards, and synchronously transmitting the information including exhaust gas data and judgment results to the monitoring center PC for real-time display, if yes, go to step 7, otherwise go to step 4 ;

[0058] Step 4, start the waste gas treatment module to purify and treat the waste gas;

[0059] Step 5, judge whether the exhaust gas treatment module is working normally, if so, go to step 7, if not, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com